Ginger wine preparation method

A technology of ginger wine and turmeric, applied in the preparation of alcoholic beverages, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problems of long time, little improvement in the spicy taste of ginger wine, etc., so as to reduce the spicy taste and shorten the Aging time, the effect of reducing alcohol loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

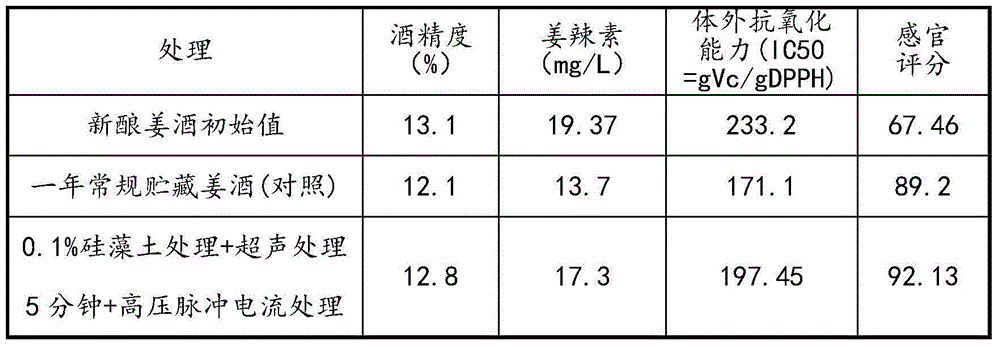

Embodiment 1

[0018] Take 100L wine as an example:

[0019] The preparation of freshly brewed ginger wine: squeeze the juice of fresh small turmeric, remove the starch, add water according to the weight ratio of ginger juice 30%, add sucrose to adjust the Bohr concentration of the fermented liquid to BIX28-30 °, Saccharomyces cerevisiae F33 according to the inoculation amount 0.25% (w / vol) was added, fermented at 20°C for 8 days, and when the alcohol content reached 12%, 100 mg / L sodium metabisulfite was added to stop the fermentation.

[0020] Add diatomaceous earth to the newly brewed ginger wine at a mass / volume ratio of 0.1%, stir evenly, let it stand at 25±1°C for 2 weeks, and pour it out. Then the wine is transferred to an ultrasonic processor for processing, the ultrasonic processing frequency is 30000MHz for 5min, and the temperature is controlled at 35°C. The processed wine liquid is then treated with high-voltage pulse current, the electric field strength is 15Kv / cm high-voltage c...

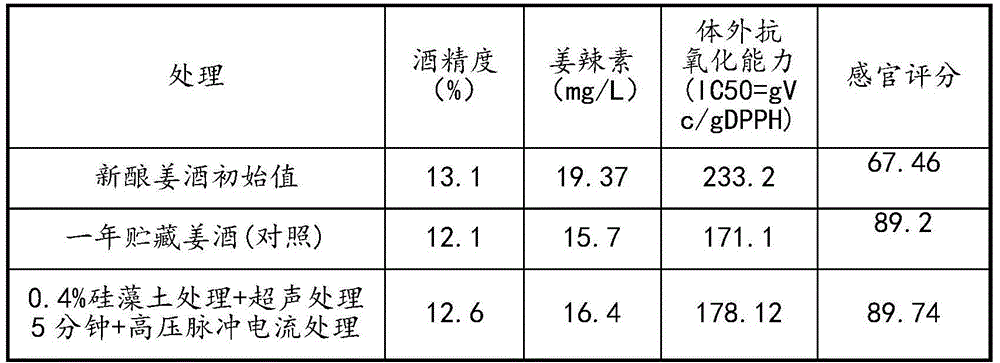

Embodiment 2

[0025] Take 100L wine as an example:

[0026] The preparation of freshly brewed ginger wine: squeeze the juice of fresh little turmeric, after removing the starch, add water by ginger juice weight ratio 30%, add sucrose to adjust the Bohr concentration of the fermented liquid to be BIX28-30 °, Saccharomyces cerevisiae F33 by 0.3% ( w / vol) ratio was added, and fermented at 20°C for 10 days. When the alcohol content reached 13%, 100mg / L sodium metabisulfite was added until the fermentation was stopped.

[0027] Add diatomaceous earth to the newly brewed ginger wine at a mass / volume ratio of 0.4%, stir evenly, let it stand at 25±1°C for 2 weeks, and pour it out. Then the liquor is transferred to an ultrasonic processor for treatment, the ultrasonic treatment frequency is 30000-35000MHz for 5 minutes, the temperature is controlled at 40°C, the treated liquor is then treated with high-voltage pulse current, the electric field strength is 20Kv / cm high-voltage current treatment, and ...

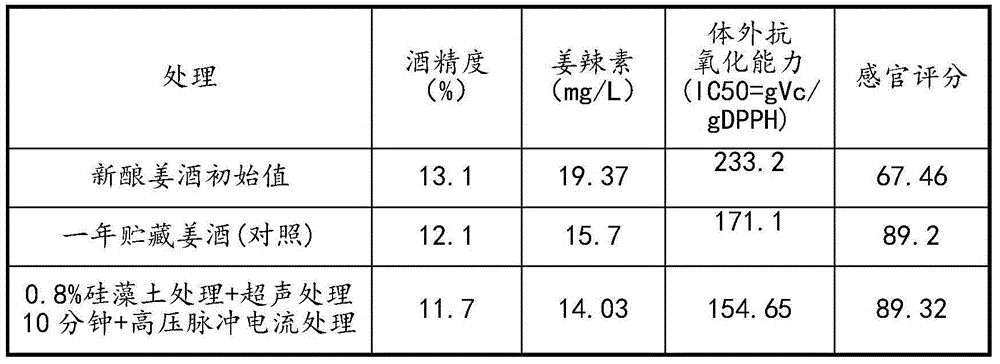

Embodiment 3

[0031] Take 100L wine as an example:

[0032] The preparation of freshly brewed ginger wine: squeeze the juice of fresh little turmeric, after removing the starch, add water by ginger juice weight ratio 30%, add sucrose to adjust the Bohr concentration of the fermented liquid to be BIX28-30 °, Saccharomyces cerevisiae F33 by 0.3% ( w / vol) ratio was added, fermented for 10 days at 20°C, and when the alcohol content reached 13%, 100 mg / L sodium metabisulfite was added to stop the fermentation.

[0033] Add diatomaceous earth to the newly brewed ginger wine at a mass / volume ratio of 0.8%, stir evenly, let it stand at 25±1°C for 2 weeks, and pour it out. Then the wine is transferred to an ultrasonic processor for treatment, the ultrasonic treatment frequency is 35000MHz for 10min, the temperature is controlled at 40°C, the treated wine is then treated with high-voltage pulse current, the electric field strength is 20Kv / cm high-voltage current treatment, and the number of pulses is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com