A method of detecting the content of triacontanol in a foliar fertilizer by applying gas chromatography

A technology of triacontanol and foliar fertilizers, which is applied in the directions of measuring devices, material separation, and material analysis, can solve problems such as bud sheath bending, young leaves curling, and root deformity at the seedling stage, and achieve fast processing and high content Detect accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

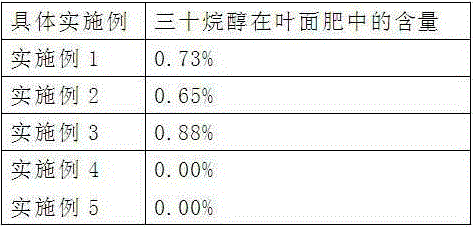

Examples

Embodiment 1

[0024] Accurately pipette 1.0g of liquid foliar fertilizer, dissolve it with 30mL of chloroform, add 5mL of phosphoric acid to it, ultrasonicate for 30min, shake for 30min, then rest for 30min, take out the lower organic phase, and continue to extract the upper emulsion with 30mL of chloroform Twice, combine the chloroform phase, rotary evaporate to near dryness, set the volume to 25mL, take 1mL to pass through a 0.22μm filter membrane, to be tested;

[0025] The above liquid to be tested was analyzed by a gas chromatograph. The gas chromatograph conditions were: HP-5 capillary column, 30mm×320μm×0.25μm; inlet temperature: 280°C, splitless; detector temperature: 320°C; Column temperature: adopt temperature program, initial temperature is 160°C, keep for 1min, increase to 320°C at 15°C / min, keep for 3min; carrier gas is nitrogen: flow rate is 1.0mL / min; injection volume: 1μL; use external standard method Obtain the concentration of triacontanol in the liquid to be tested, and t...

Embodiment 2

[0027] Accurately pipette 1.0g of powder foliar fertilizer, dissolve it with 30mL of chloroform, add 5mL of phosphoric acid to it, sonicate for 30min, shake for 30min, rest for 30min, centrifuge at 8000rpm for 5min, remove the precipitate, add the supernatant to 20mL of ultrapure water in a separatory funnel, shake intermittently for 5 minutes, and stand still for 30 minutes. After the chloroform phase and the water phase are separated, remove the chloroform phase, rotary evaporate to near dryness, set the volume to 25mL, and take 1mL to pass through 0.22μm filter membrane, to be tested;

[0028] The above liquid to be tested was analyzed by a gas chromatograph. The gas chromatograph conditions were: HP-5 capillary column, 30mm×320μm×0.25μm; inlet temperature: 300°C, splitless; detector temperature: 330°C; Column temperature: adopt temperature program, the initial temperature is 200°C, keep for 1min, rise to 320°C at 15°C / min, keep for 3min; carrier gas is nitrogen: flow rate ...

Embodiment 3

[0030] Accurately pipette 1.0g of crushed solid foliage fertilizer, dissolve it with 30mL of chloroform, add 5mL of phosphoric acid to it, ultrasonicate for 30min, shake for 30min, rest for 30min, centrifuge at 8000rpm for 5min, remove the precipitate, add the supernatant to 20mL In ultrapure water, transfer to a separatory funnel, shake intermittently for 5 minutes, and let stand for 30 minutes. After the chloroform phase and the water phase are separated, remove the chloroform phase, rotary evaporate to nearly dryness, set the volume to 25mL, and take 1mL Pass through a 0.22μm filter membrane, to be tested;

[0031] The above-mentioned liquid to be tested is analyzed by a gas chromatograph, and the conditions of the gas chromatograph are: the conditions of the gas chromatograph include HP-5 capillary chromatographic column, 30mm×320μm×0.25μm; the temperature of the inlet: 300°C, splitless; the detection Detector temperature: 320°C; column temperature: adopt temperature progr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com