Two-dimensional reflection type supersonic wave wind speed anemoscope and measuring method

An anemometer, wind speed and direction technology, applied in the direction of fluid velocity measurement, velocity/acceleration/impact measurement, measuring device, etc., can solve the problems of many measurements, shortened service life, fast wear of moving parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

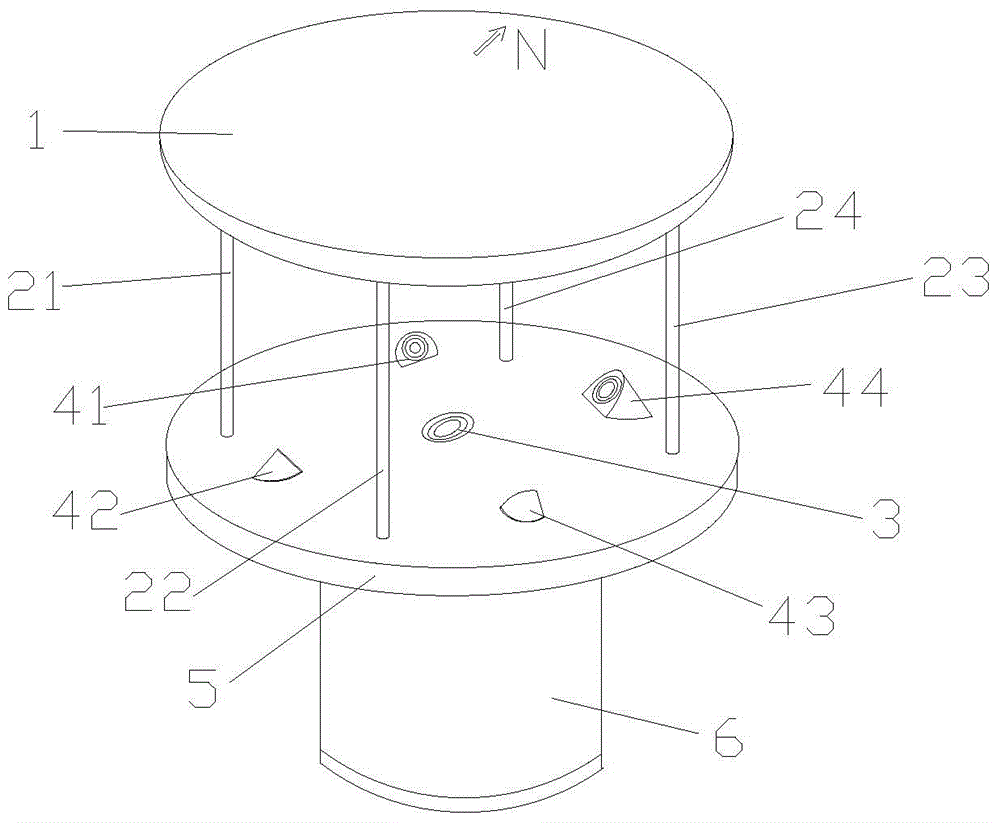

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

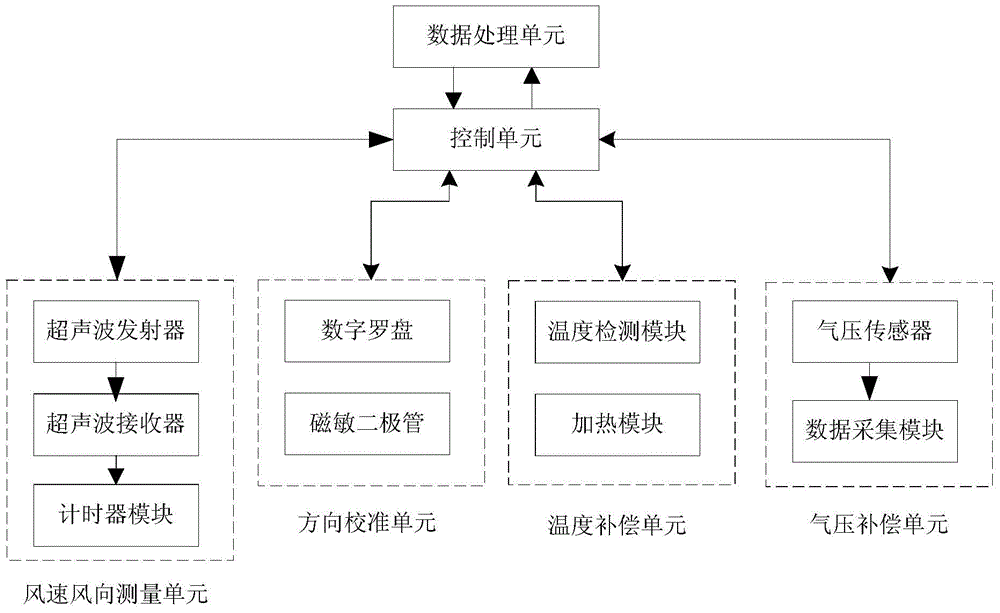

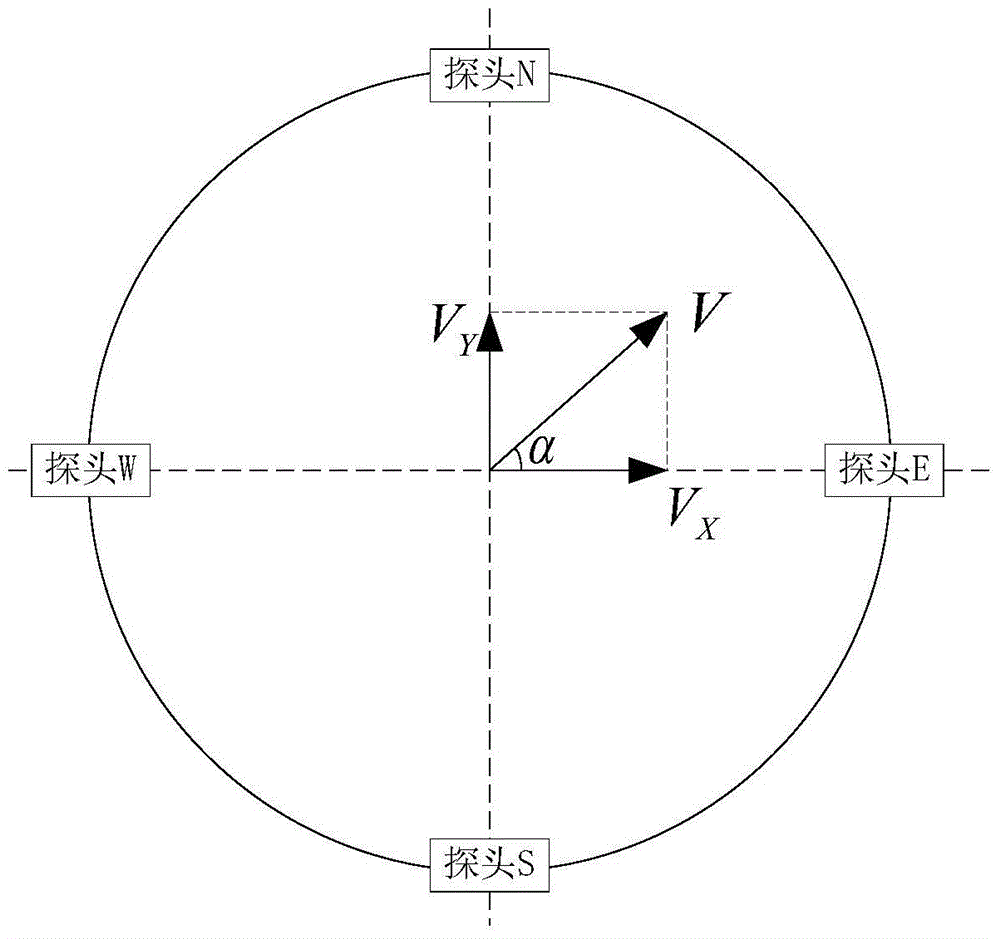

[0043] Such as figure 1 As shown, the core of the ultrasonic anemometer of the present invention is the control unit, which is connected with the data processing unit to process relevant data during the measurement process and obtain the final wind speed and direction data. It is connected with the wind speed and direction measurement unit to control the transmission and reception of ultrasonic waves, and start and close the timer module through interrupts to obtain the propagation time of ultrasonic waves. It is connected with the direction calibration unit to determine the reference direction, that is, the direction of the geographic north pole (magnetic south pole), which is used to calibrate the wind direction data to make it consistent with the actual wind direction. It is connected with the temperature compensation module, and judges whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com