Diffusion process for making solar cells

A solar cell and diffusion process technology, which is applied in the field of solar cell diffusion process, can solve the problems that the phosphorus concentration affects the uniformity of diffusion sheet resistance, reduces the concentration of phosphorus, and affects the uniformity of sheet resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

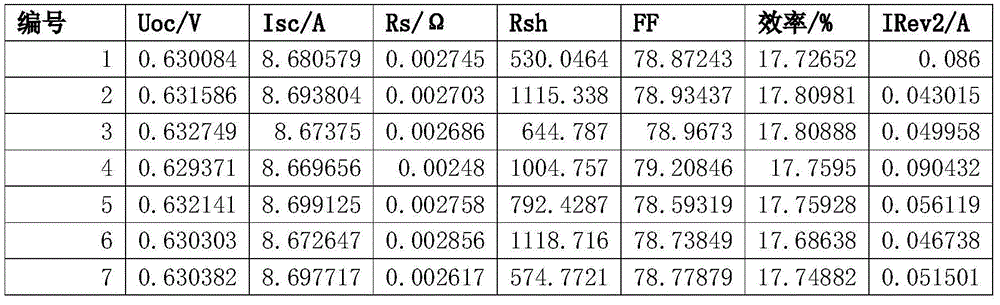

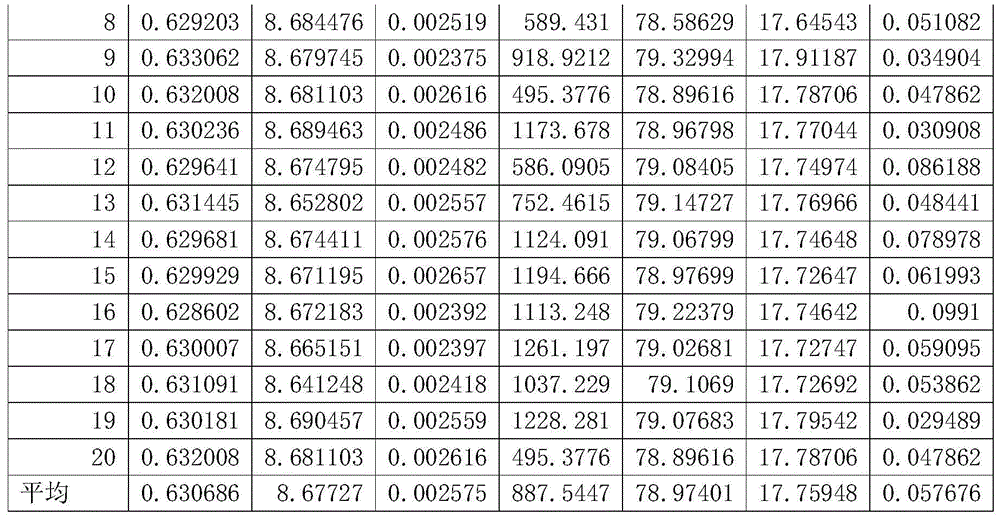

Image

Examples

Embodiment 1

[0025] The embodiment of the present invention discloses a diffusion process for making a solar cell, which includes the following steps:

[0026] 1) Control the temperature in the furnace at 840°C;

[0027] 2) At this temperature, feed 200ml / min of oxygen and 750ml / min of small nitrogen concentration, and at the same time feed 11000mL / min of large nitrogen to diffuse on the polysilicon wafer to form the first layer of diffusion thin layer, and the treatment time is 8min ;

[0028] 3) Introduce 200ml / min of oxygen and 700ml / min of small nitrogen concentration, and at the same time, inject 11000mL / min of large nitrogen, and diffuse again, and the treatment time is 11min;

[0029] 4) Stop the flow of the phosphorus source, and lower the temperature to 700°C in 25 minutes. During the entire cooling process, 2000ml / min of oxygen and 10000mL / min of nitrogen are continuously introduced to promote the impurity. Deep push, reduce the surface impurity concentration, thereby reducing ...

Embodiment 2

[0032] The embodiment of the present invention discloses a diffusion process for making a solar cell, which includes the following steps:

[0033] 1) Control the temperature in the furnace at 840°C;

[0034] 2) At this temperature, feed 500ml / min of oxygen and 1000ml / min of small nitrogen concentration, and at the same time feed 15000mL / min of large nitrogen to diffuse on the polysilicon wafer to form the first layer of diffusion thin layer, and the processing time is 8min ;

[0035] 3) Pass through 500ml / min of oxygen and 900ml / min of small nitrogen concentration, and at the same time pass through 15000mL / min of large nitrogen, and diffuse again, and the treatment time is 16 minutes;

[0036] 4) Stop the flow of the phosphorus source, and reduce the temperature to 700°C in 40 minutes. During the entire cooling process, 2500ml / min of oxygen and 15000mL / min of nitrogen are continuously introduced to promote the impurity. Deep push, reduce the surface impurity concentration, t...

Embodiment 3

[0039] The embodiment of the present invention discloses a diffusion process for making a solar cell, which includes the following steps:

[0040] 1) Control the temperature in the furnace at 840°C;

[0041] 2) At this temperature, feed 300ml / min of oxygen and 900ml / min of small nitrogen concentration, and at the same time feed 12000mL / min of large nitrogen to diffuse on the polysilicon wafer to form the first layer of diffusion thin layer, and the treatment time is 12min ;

[0042] 3) Pass 300ml / min of oxygen and 900ml / min of small nitrogen concentration, and at the same time pass through 12000mL / min of large nitrogen, and diffuse again, and the treatment time is 15min;

[0043] 4) Stop the flow of the phosphorus source, and lower the temperature to 780°C in 30 minutes. During the entire cooling process, 2300ml / min of oxygen and 12000mL / min of nitrogen are continuously introduced to promote the impurity. Deep push, reduce the surface impurity concentration, thereby reducing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com