Egg compound feed

A technology for compound feed and laying hens, which is applied to the field of compound feed for laying hens, can solve the problems of difficulty in regulating energy intake by feed intake, low-energy feed containing more fiber, and reduced egg production, etc. Satisfy the needs of survival and egg production, and inhibit the effect of reducing components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A compound feed for laying hens is composed of the following parts by weight: corn 52.5, soybean meal 15, cottonseed meal 8.5, peanut meal 6.7, wheat bran 15, soybean oil 0.95, salt 0.35, stone powder 0.9, gravel 0.1.

[0020] The preparation method of described laying hen compound feed is:

[0021] 1. Mix and pulverize soybean meal, cotton kernel meal and peanut meal to obtain mixed meal, and then sterilize with high-temperature steam at a controlled temperature of 105°C to 135°C for 15 to 25 minutes;

[0022] 2. Lower the temperature to 23°C-25°C, add 0.5-1.5% of the total amount of mixed meal with Lactobacillus for anaerobic solid fermentation for 2-4 days;

[0023] 3. Raise the temperature to 26°C-30°C, add 0.5-1.5% of the total amount of mixed meal to the aerobic solid fermentation of Saccharomyces cerevisiae for 2-4 days;

[0024] 4. Raise the temperature to 32°C-38°C, add 1-3% of the total amount of mixed meal to the aerobic solid fermentation of Bacillus for 0....

Embodiment 2

[0031] A compound feed for laying hens is composed of the following parts by weight: corn 55, soybean meal 12, cottonseed meal 8, peanut meal 8, wheat bran 15, soybean oil 0.5, salt 0.4, stone powder 1, gravel 0.1.

[0032] The preparation method of described laying hen compound feed is:

[0033] 1. Mix and pulverize soybean meal, cotton kernel meal and peanut meal to obtain mixed meal, and then sterilize with high-temperature steam at a temperature of 115°C for 25 minutes;

[0034] 2. Lower the temperature to 23°C-25°C, add 0.5-1.5% of the total amount of mixed meal with Lactobacillus for anaerobic solid fermentation for 2-4 days;

[0035] 3. Raise the temperature to 26°C-30°C, add 0.5-1.5% of the total amount of mixed meal to the aerobic solid fermentation of Saccharomyces cerevisiae for 2-4 days;

[0036] 4. Raise the temperature to 32°C-38°C, add 1-3% of the total amount of mixed meal to the aerobic solid fermentation of Bacillus for 0.5-1d;

[0037] 5. Drying the mixed ...

Embodiment 3

[0040] A compound feed for laying hens is composed of the following parts by weight: corn 50, soybean meal 15, cottonseed meal 10, peanut meal 8, wheat bran 15, soybean oil 1, salt 0.3, stone powder 0.6, gravel 0.1.

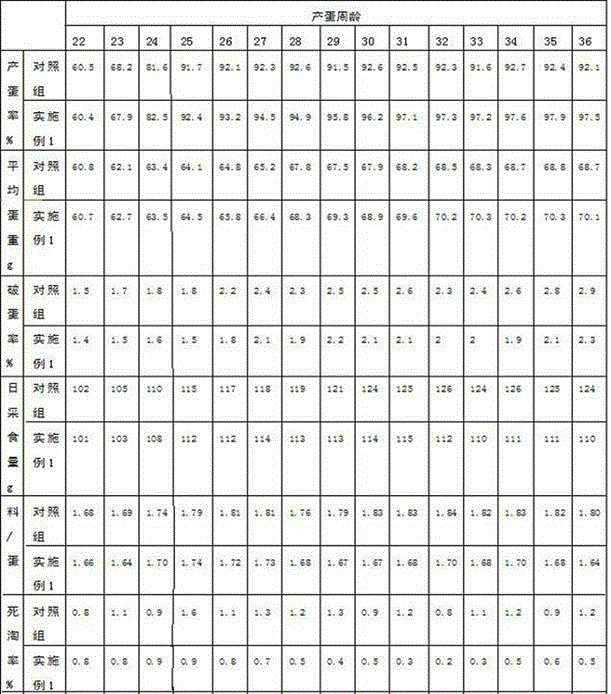

[0041] Below with embodiment 1 and corn-soybean meal type diet, laying hen production performance and dead rate are compared, table one:

[0042]

[0043] As can be seen from the comparison in Table 1, the laying hen feed provided by the application is fed in the laying cycle of 22 to 36 weeks of age, and the feed of the application is fed, and the egg production rate is increased by nearly 5%, the egg weight increases, and the eggs are broken The rate is reduced, the feed intake is reduced, and the dead elimination rate is reduced, which greatly increases the economic benefits of the breeders.

[0044] In the formula of the present invention, the metabolic energy is moderate, and the amount of soybean meal is reduced, and no fish meal or bone meal is used, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com