Tapered lining of conical crusher and casting process of tapered lining

A cone crusher and cone bushing technology, which is applied in the manufacture of tools, casting molding equipment, casting molds, etc., can solve the problems of difficult casting and difficult to guarantee the quality of the overall bushing of the main shaft, so as to speed up heat dissipation and air discharge, reduce Effect of small sticky sand defect and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

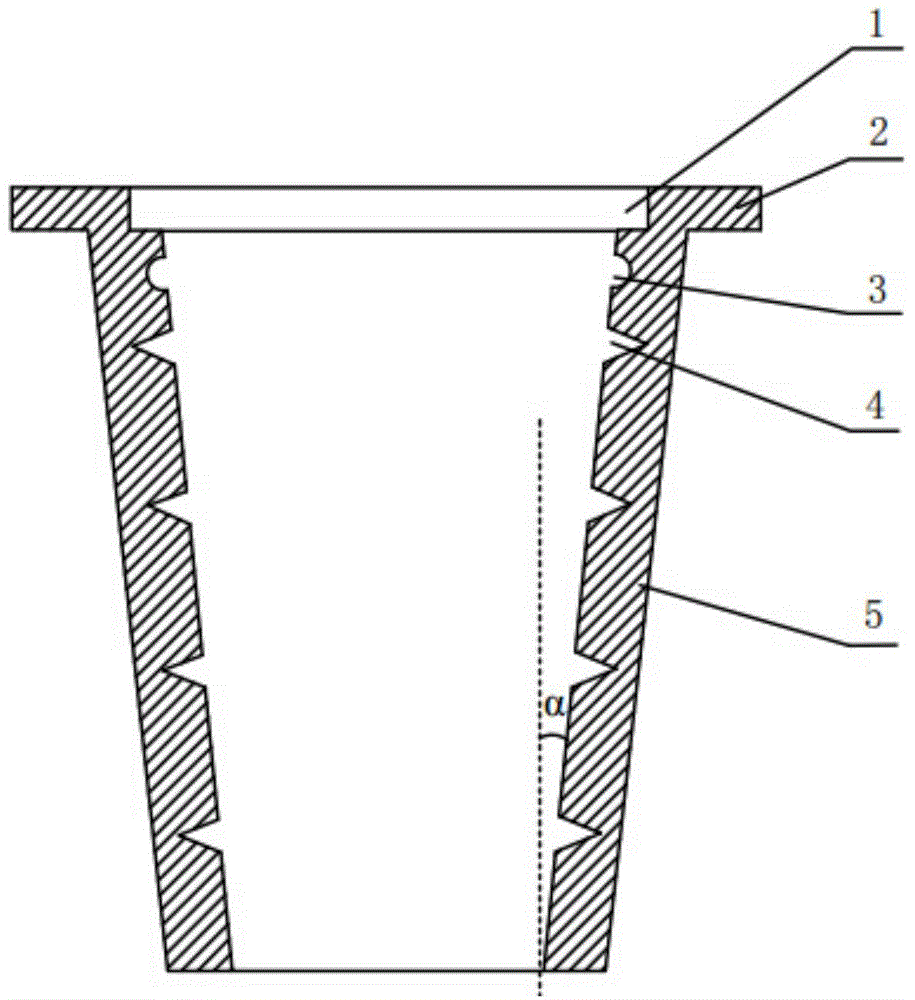

[0028] like figure 1 As shown, a conical bushing of a cone crusher, the bushing is a hollow frustum 5 made of high manganese steel, the upper bottom of the frustum 5 is larger than the bottom; The inner surface of 5 is provided with several annular grooves 4 transversely, the cross-sectional shape of said annular grooves 4 is triangular, and the number of said annular grooves 4 is four. The inclination angle α of the tapered bush in the vertical direction is 15 degrees.

[0029] The inner surface above the annular groove 4 is provided with several grooves 3 for storing lubricating oil, and the grooves 3 are evenly distributed on an annular surface of the inner surface of the circular frustum; the cross-sectional shape of the groove 3 is circle.

[0030] The upper top of the truncated truncated body 5 is provided with a limit structure 2, and the limited structure 2 is arranged around the periphery of the truncated truncated body top and extends outward; The step hole 1 of t...

Embodiment 2

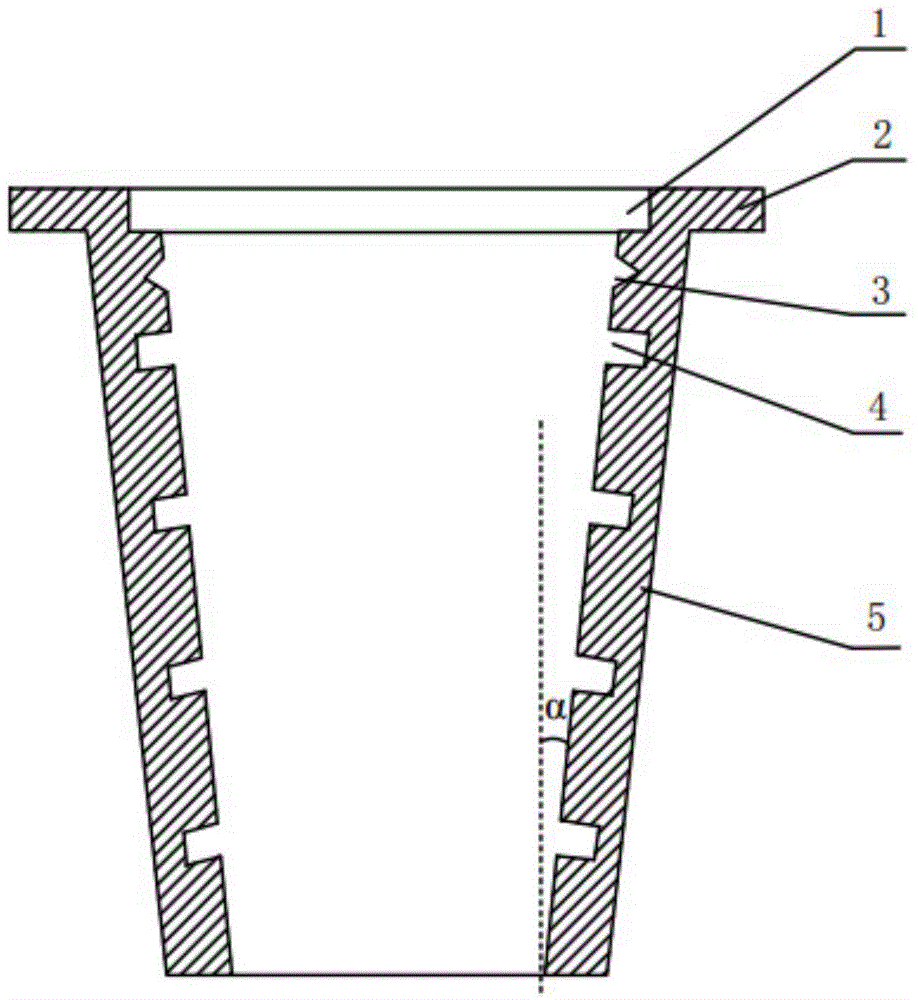

[0039] like figure 2 As shown, a conical bushing of a cone crusher, the bushing is a hollow frustum 5 made of high manganese steel, the upper bottom of the frustum 5 is larger than the bottom; The inner surface of 5 is provided with several annular grooves 4 transversely, the cross-sectional shape of said annular grooves 4 is square, and the number of said annular grooves 4 is four. The inclination angle α of the tapered bush in the vertical direction is 15 degrees.

[0040] The inner surface above the annular groove 4 is provided with several grooves 3 for storing lubricating oil, and the grooves 3 are evenly distributed on an annular surface of the inner surface of the circular frustum; the cross-sectional shape of the groove 3 is triangle.

[0041] The upper top of the truncated truncated body 5 is provided with a limit structure 2, and the limited structure 2 is arranged around the periphery of the truncated truncated body top and extends outward; The step hole 1 of th...

Embodiment 3

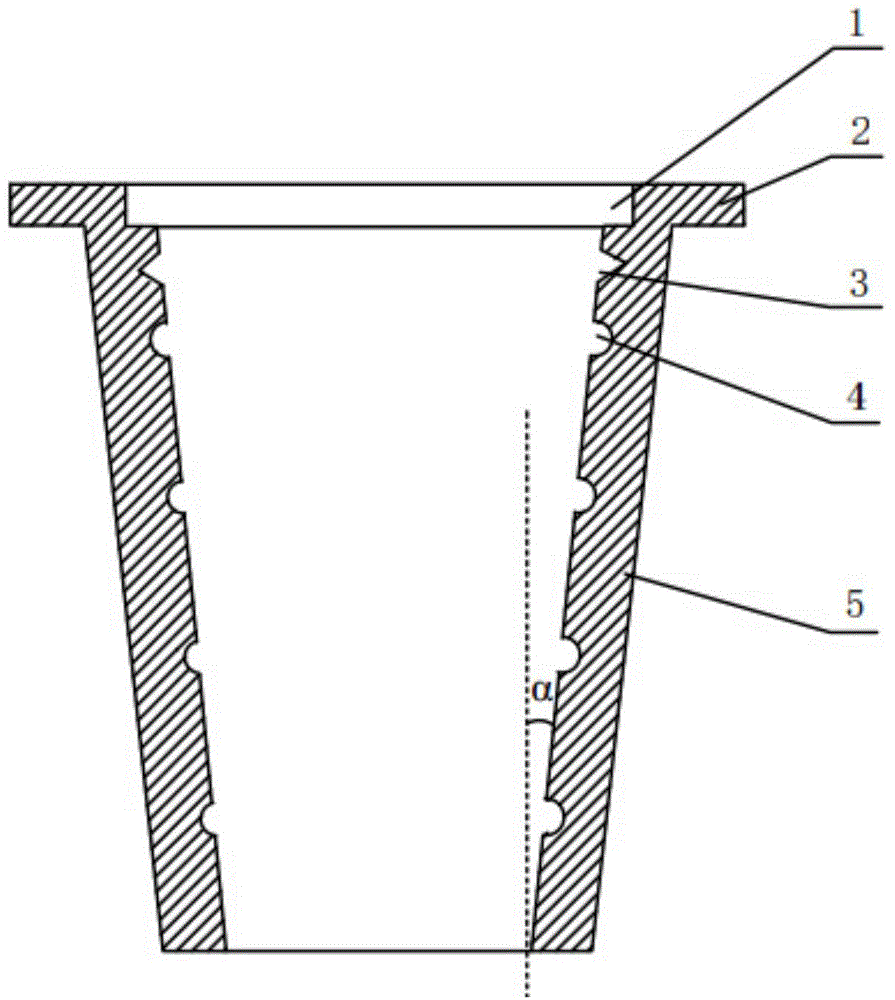

[0045] like image 3 As shown, a conical bushing of a cone crusher, the bushing is a hollow frustum made of high manganese steel, the upper bottom of the frustum is larger than the lower bottom; the inner frustum of the frustum There are several annular grooves arranged laterally on the surface, the cross-sectional shape of the annular grooves is arc-shaped, and the number of the annular grooves is four. The inclination angle α of the tapered bush in the vertical direction is 12 degrees.

[0046] The inner surface above the annular groove is provided with several grooves for storing lubricating oil, and the grooves are evenly distributed on an annular surface of the inner surface of the circular frustum; the cross-sectional shape of the grooves is square.

[0047] The upper top of the conical truncated body is provided with a limiting structure, and the limiting structure is arranged around the periphery of the top of the conical truncated body and extends outward; the upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com