Sugar mill millroller shaft neck wear repairing method

A repair method and sugar press technology, applied in the field of metal surface engineering, can solve the problems of unsuitable parts maintenance, inability to solve the material, high cost, etc., to avoid material brittleness and thermal stress, avoid large stress, and dense working layer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

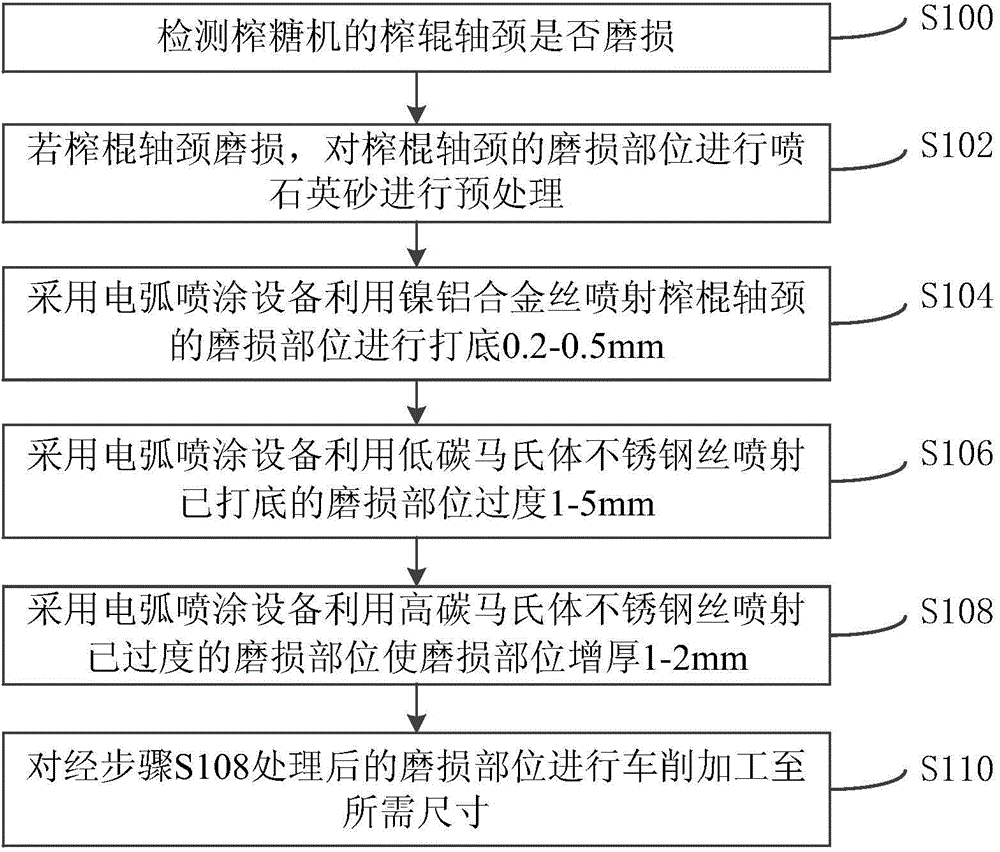

[0026] Such as figure 1 As shown, according to a specific embodiment of the present invention, a method for repairing the press roll journal wear of a sugar press comprises the following steps:

[0027] Step S100: Detect whether the press roller journal of the sugar extractor is worn.

[0028] Step S102: if the journal of the pressing stick is worn, pre-treat the worn part of the journal of the pressing stick by spraying quartz sand;

[0029] In this step, the wear part is firstly processed by rough turning, and then the dry clean air with a flow rate of 3-4 cubic meters or more and 10-12MP is used to pretreat the wear part of the journal of the pressing stick with quartz sand to obtain the best activated metal surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com