Light-weight flexible irradiation-resistant cover glass and preparation method thereof

A glass cover sheet, anti-radiation technology, applied in glass manufacturing equipment, glass production, glass cutting devices, etc., can solve the problems of aerospace vehicles losing power supply, unable to guarantee solar light transmittance, and reducing transmittance, etc. To achieve the effect of reducing density, good resistance to space particle impact, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

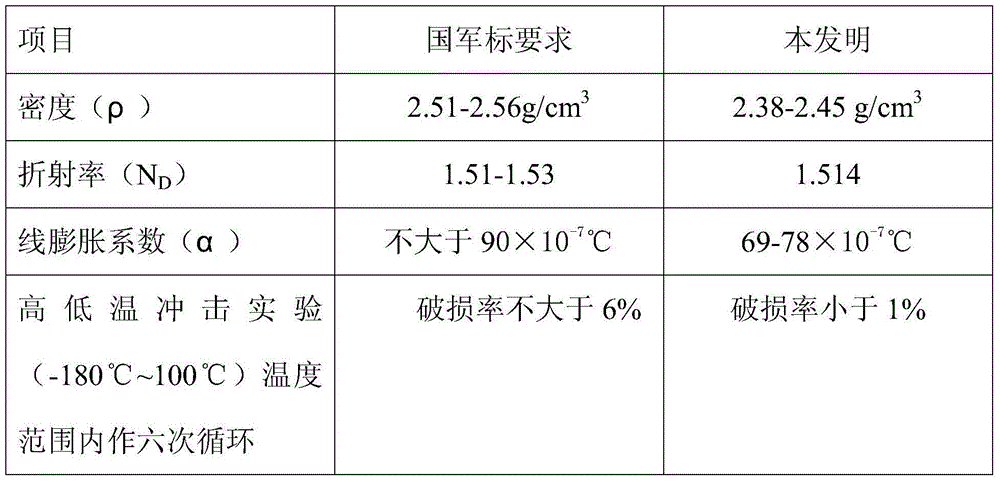

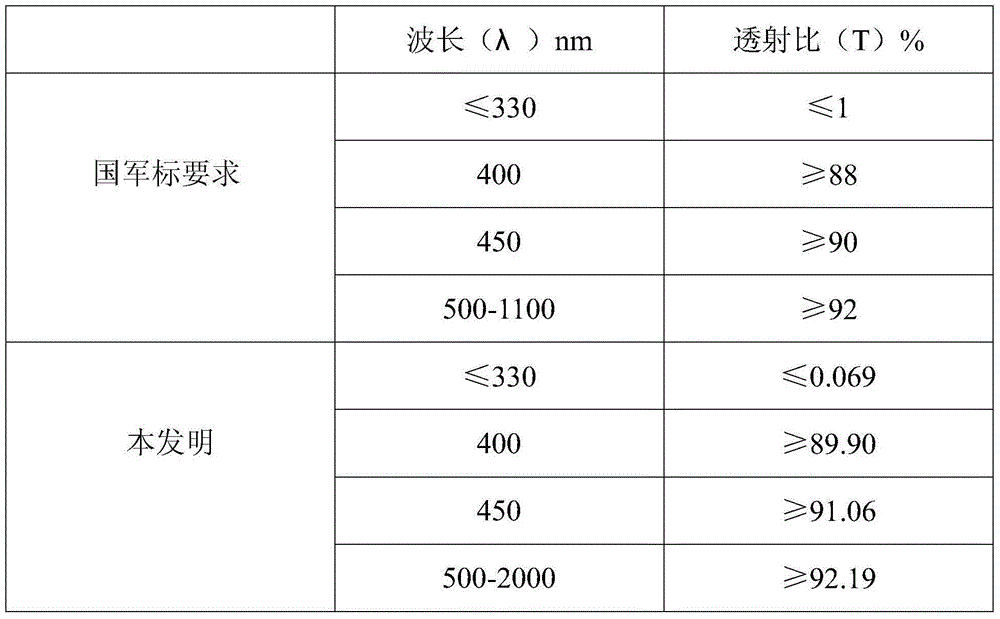

Examples

Embodiment 1

[0032] A light-weight flexible radiation-resistant glass cover sheet, the raw material composition of which is: by mass percentage, SiO 2 : 53.9%, Al 2 o 3 : 0.5%, B 2 o 3 : 13.2%, MgO: 8.8%, Na 2 O: 5.1%, Li 2 O: 12.5%, K 2 O: 0.1%, CeO 2 : 4.8%, P 2 o 5 : 1.1%. All the raw materials are of analytical grade.

[0033] The preparation method of the light-weight flexible radiation-resistant glass cover sheet is as follows:

[0034] A. Ingredients: Weigh each raw material according to the raw material composition of the above-mentioned cover glass, mix evenly, and set aside;

[0035] B. Feeding: Take the melting crucible and heat it. When the temperature of the melting crucible is 700-800°C, carry out the first stage of feeding. The amount of feeding is the entire volume of the melting crucible; after the first stage of feeding, continue to heat up. When the temperature is 1530-1560°C, the second stage of feeding is carried out. At this time, since part of the raw mat...

Embodiment 2

[0046] A light-weight flexible radiation-resistant glass cover sheet, the raw material composition of which is: by mass percentage, SiO 2 : 50.8%, Al 2 o 3 : 0.7%, B 2 o 3 : 15.9%, MgO: 10.2%, Na 2 O: 6%, Li 2 O: 11.1%, K 2 O: 0.5%, CeO 2 : 4.6%, P 2 o 5 : 0.2%. All the raw materials are of analytical grade.

[0047] The preparation method of the light-weight flexible radiation-resistant glass cover sheet is as follows:

[0048] A. Ingredients: Weigh each raw material according to the raw material composition of the above-mentioned cover glass, mix evenly, and set aside;

[0049] B. Feeding: Take the melting crucible and heat it. When the temperature of the melting crucible is 700-800°C, carry out the first stage of feeding. The amount of feeding is the entire volume of the melting crucible; after the first stage of feeding, continue to heat up. When the temperature is 1530-1560°C, the second stage of feeding is carried out. At this time, since part of the raw mate...

Embodiment 3

[0060] A light-weight flexible radiation-resistant glass cover sheet, the raw material composition of which is: by mass percentage, SiO 2 : 53%, Al 2 o 3 : 0.6%, B 2 o 3 : 14%, MgO: 9.5%, Na 2 O: 5%, Li 2 O: 12.5%, K 2 O: 0.2%, CeO 2 : 4.7%, P 2 o 5 : 0.5%. All the raw materials are of analytical grade.

[0061] The preparation method of the light-weight flexible radiation-resistant glass cover sheet is as follows:

[0062] A. Ingredients: Weigh each raw material according to the raw material composition of the above-mentioned cover glass, mix evenly, and set aside;

[0063] B. Feeding: Take the melting crucible and heat it. When the temperature of the melting crucible is 700-800°C, carry out the first stage of feeding. The amount of feeding is the entire volume of the melting crucible; after the first stage of feeding, continue to heat up. When the temperature is 1530-1560°C, the second stage of feeding is carried out. At this time, since part of the raw materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com