Thermoplastic elastomer medical film material

A thermoplastic elastic and film material technology, applied in the field of medical film materials, can solve the problems of poor low temperature resistance and elasticity, poor aging resistance, narrow hardness range, etc., achieve good low temperature resistance and heat aging resistance, and simple processing procedures , the effect of a wide range of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

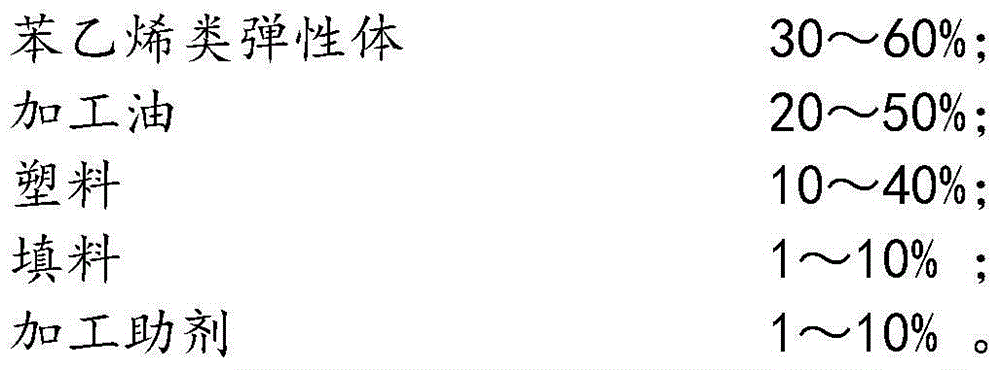

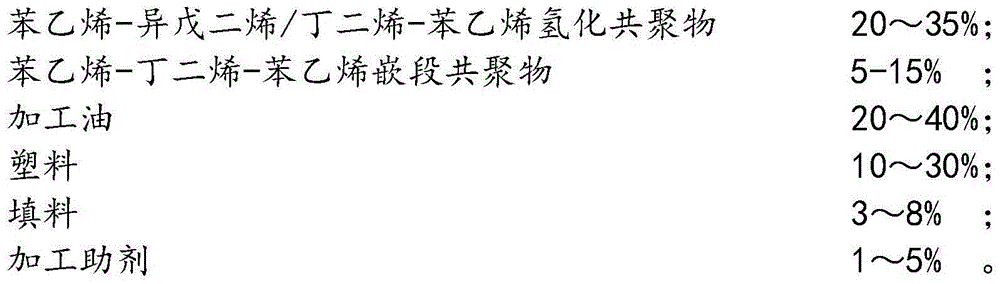

Method used

Image

Examples

Embodiment 1

[0032] Molding process: extrusion blown film

[0033] Process flow: high-speed oil absorption of styrene elastomer → oil absorption and standing → batching → twin-screw extrusion → granulation

[0034] Processing parameters:

[0035] Cylinder temperature

set value

Feed section temperature

170℃

front temperature

175℃

middle temperature

190℃

back temperature

145℃

Die temperature

140℃

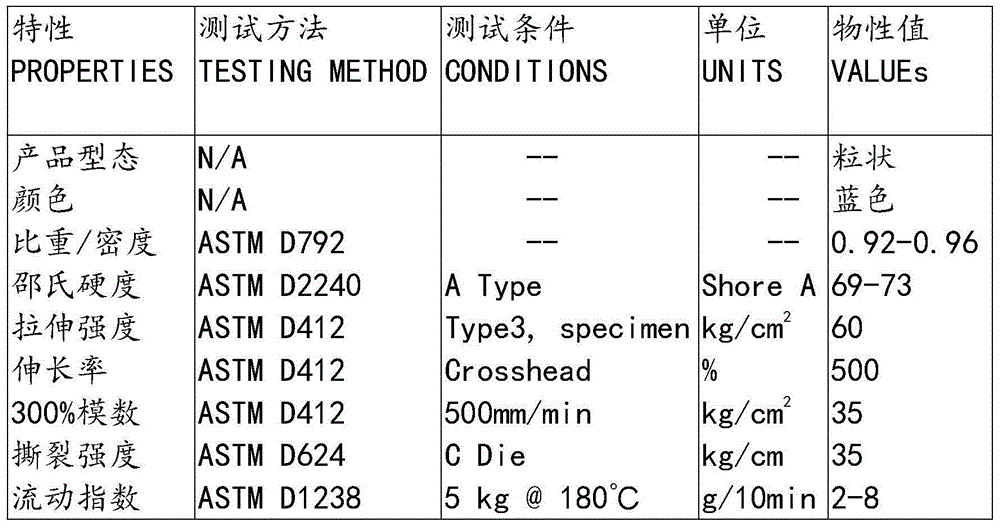

[0036] Physical properties:

[0037]

Embodiment 2

[0039] raw material

Embodiment 3

[0041] raw material

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com