Thickening agent for liquid carbon dioxide fracturing and preparation method thereof

A thickener and fracturing technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of ineffective thickening effect, high wellbore friction, and high construction pressure, and improve sand-carrying performance. , The effect of increasing viscosity and reducing filtration loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take 25g of clear water and 10g of isopropanol 1000 into the flask, heat to 60°C, add 15g of acetic acid, stir to dissolve, then add 30g of octadecyltrimethylammonium chloride, 20g of octadecyldihydroxyethyl Ammonium methyl ammonium nitrate, keep the temperature at 60°C, stir for 30 minutes, after it is completely dissolved, cool to room temperature to obtain liquid CO 2 Viscosifier for fracturing.

Embodiment 2

[0038] Take 55g of clear water and 10g of ethanol into the flask, heat to 60°C, add 5g of citric acid, stir to dissolve, then add 20g of octadecyltrimethylammonium bromide, 10g of octadecyldihydroxyethylmethyl ammonium bromide, keep the temperature at 60°C, stir for 30 minutes, after all dissolve evenly, cool to room temperature to obtain liquid CO 2 Viscosifier for fracturing.

Embodiment 3

[0040] Take 15g of clear water and 20g of methanol into the flask, heat to 60°C, add 15g of salicylic acid, stir to dissolve, then add 30g of cetyltrimethylammonium bromide, 20g of octadecyldihydroxyethyl Methyl ammonium chloride, keep the temperature at 60°C, stir for 30 minutes, after it is completely dissolved, cool to room temperature to obtain liquid CO 2 Viscosifier for fracturing.

PUM

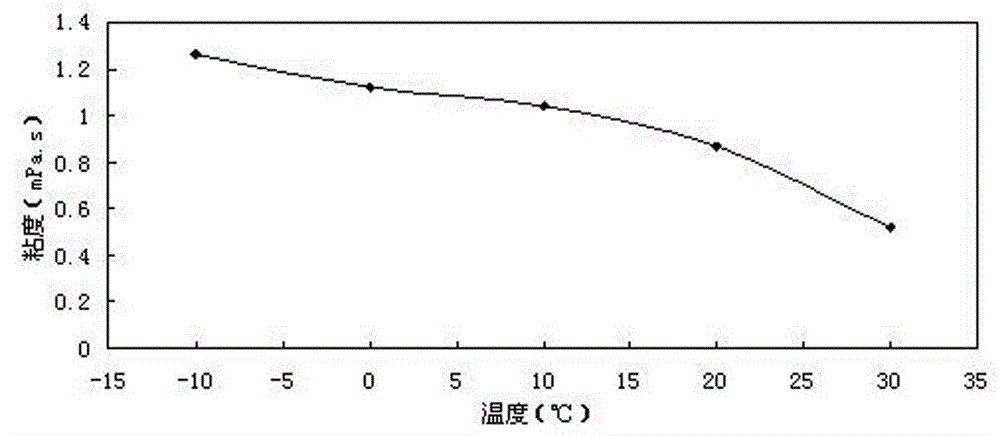

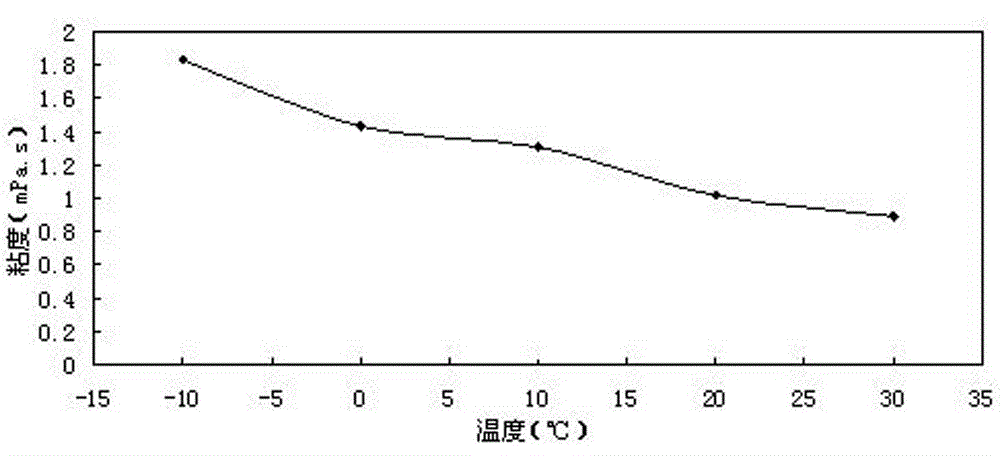

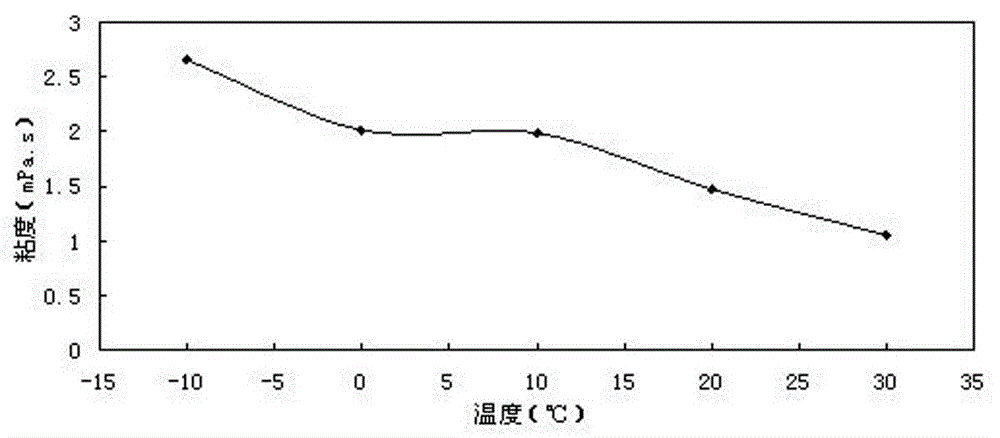

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com