Method for improving cellulase use efficiency, and apparatus thereof

A technology of cellulase and cellulose, which is applied in the direction of biochemical equipment and methods, enzymes, enzymes, etc., can solve the problems of product inhibition, reduce the efficiency of cellulase use, and reduce the efficiency of enzymatic hydrolysis, so as to increase the contact area and the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

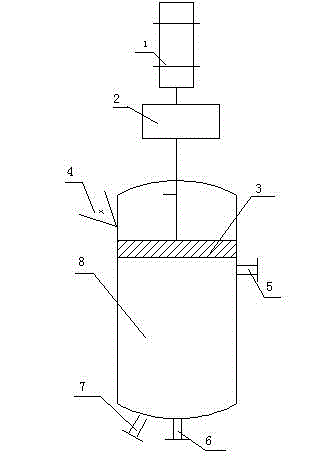

Image

Examples

Embodiment 1

[0031] (1) Processing of bagasse

[0032] 1. Take by weighing 10kg of dry bagasse, use 30L mass concentration of 5% dilute sulfuric acid to process the cellulose raw material to extract the hemicellulose in the cellulose raw material;

[0033] ② Filter out the solid from the solution treated in step (1) ①, wash the solid with water until the pH is 6.5-7.0; collect the filtrate at the same time, and the filtrate is dilute sulfuric acid liquid containing hemicellulose;

[0034] ③ Soak the solid obtained through step (1) ② with an aqueous sodium hydroxide solution with a mass concentration of 15% at 120 degrees for 5 hours to remove lignin, filter out the processed bagasse, and oxidize The mass ratio of sodium aqueous solution to solid is 10:1;

[0035] ④ Dilute sulfuric acid liquid containing hemicellulose Continue to process the untreated cellulose in step (1) ①, and then go through step (1) ② to obtain dilute sulfuric acid liquid containing hemicellulose, which can be used re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com