Carbide-reinforced Mo2NiB2 metal ceramic and preparation method thereof

A cermet and carbide technology, which is applied in the field of carbide-reinforced Mo2NiB2 cermet and its preparation, can solve the problem that the research on cermet materials has not been reported, and achieve the effects of short preparation cycle, simple process and high material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

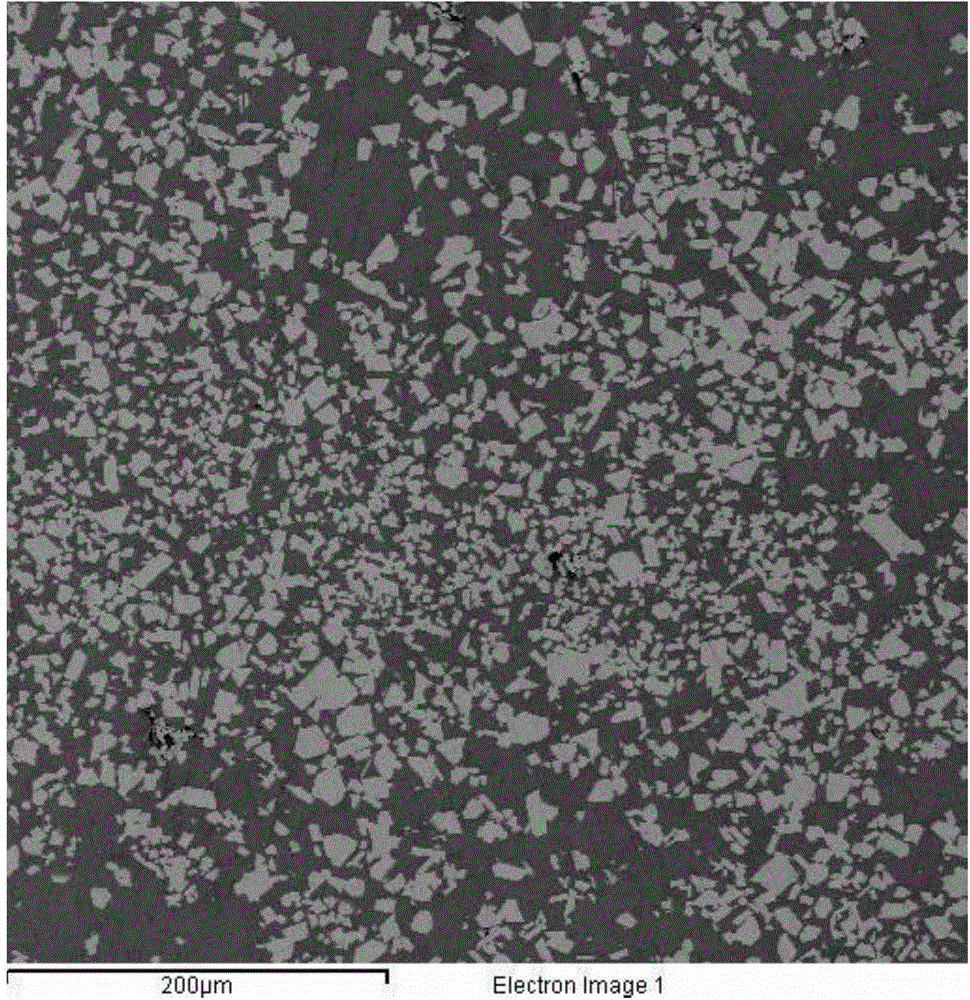

Image

Examples

preparation example Construction

[0025] The carbide reinforced Mo provided by the present invention 2 NiB 2 A method for preparing a cermet material, comprising the following steps:

[0026] 1) Use Mo powder, B powder, Ni powder and graphite powder with a purity of not less than 99.9% as the main raw materials, and the mass ratio is Ni:B:Mo:C=(21~45):6:(44~63) : (5~10) For batching, the particle size of Mo powder and graphite powder is required to be ≤20 μm, and the particle size of B powder and Ni powder is ≤50 μm.

[0027] Put Mo powder and graphite powder into a high-energy ball mill tank, fill it with argon gas and carry out mechanical alloying for 24.5-25.5 hours, then add B powder and Ni powder, and mix for 5-10 hours to obtain a mixed powder.

[0028] 2) Take out the mixed powder, and perform compression molding in a metal mold to obtain a green body, and the molding pressure is 150-300 MPa.

[0029] Put the molded green body into a vacuum sintering furnace for pressureless sintering, the vacuum deg...

Embodiment 1

[0033] 1) Use Mo powder, B powder, Ni powder and graphite powder with a purity of not less than 99.9% as the main raw materials. The particle size of Mo powder and graphite powder is required to be ≤20 μm, and the particle size of B powder and Ni powder is ≤50 μm. According to the mass ratio: Ni:B:Mo:C=41:6:48:5 for batching.

[0034] Put Mo powder and graphite powder into a high-energy ball mill tank, fill it with argon gas and carry out mechanical alloying for 25 hours, then add B powder and Ni powder, and mix for 10 hours to obtain a mixed powder.

[0035] 2) Take out the mixed powder, and perform compression molding in a metal mold to obtain a green body, and the molding pressure is 150 MPa.

[0036] Put the molded green body into a vacuum sintering furnace for pressureless sintering, the vacuum degree is ≤10 -2 Pa, from room temperature to the sintering temperature of 1240°C at a heating rate of 10°C / min, after reaching the sintering temperature without heat preservation...

Embodiment 2

[0039] 1) Use Mo powder, B powder, Ni powder and graphite powder with a purity of not less than 99.9% as the main raw materials. The particle size of Mo powder and graphite powder is required to be ≤20 μm, and the particle size of B powder and Ni powder is ≤50 μm. According to the mass ratio: Ni:B:Mo:C=32.7:6:53.3:8 for batching.

[0040] Put Mo powder and graphite powder into a high-energy ball mill tank, fill it with argon gas and carry out mechanical alloying for 25 hours, then add B powder and Ni powder, and mix for 10 hours to obtain a mixed powder.

[0041] 2) Take out the mixed powder, and perform compression molding in a metal mold to obtain a green body, and the molding pressure is 180 MPa.

[0042] Put the molded green body into a vacuum sintering furnace for pressureless sintering, the vacuum degree is ≤10 -2 Pa, from room temperature to the sintering temperature of 1260°C at a heating rate of 10°C / min, after reaching the sintering temperature without heat preserva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com