Sensor and its manufacturing method

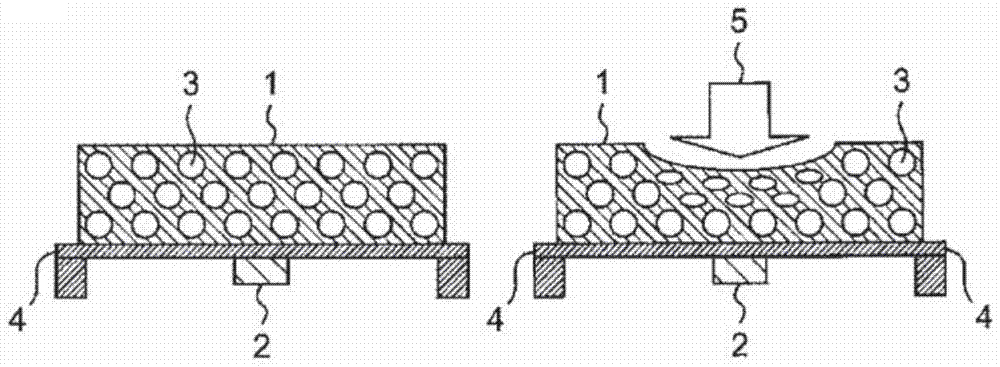

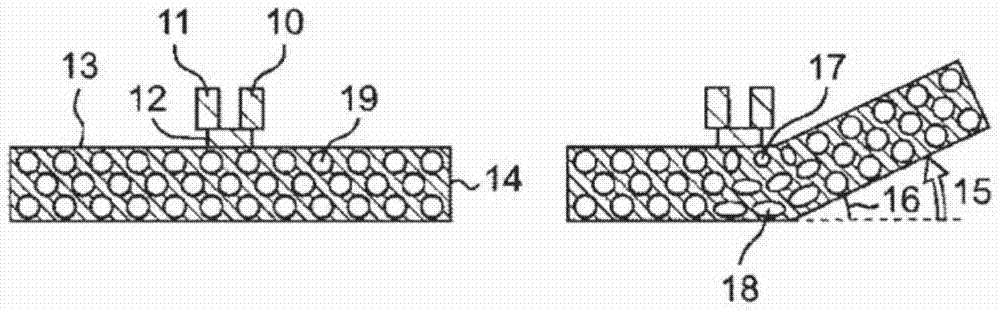

A manufacturing method and sensor technology, applied in the field of sensors, can solve problems such as difficulty in detecting deformation, deterioration in detection sensitivity, and difficulty in moving a magnet, and achieve the effect of improving sensitivity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

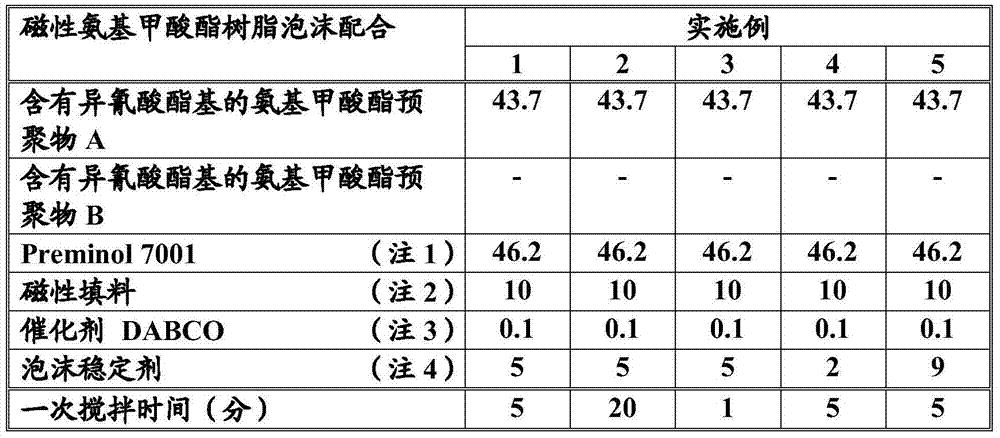

[0062] As methods for preparing urethane resin foams, conventionally there are chemical foaming methods in which reactive foaming agents such as water are used; and mechanical foaming methods in which polyisocyanate components and reactive The mixture of hydrogen component and catalyst is mechanically stirred. It is well known that the molding operation in the above-mentioned mechanical foaming method is simpler than that in the above-mentioned chemical foaming method, and because water is not used as a foaming agent, no urea groups are generated, so that the physical properties are not reduced, and the mechanical foaming method Molded articles having excellent toughness, excellent resilience, and the like can be obtained. However, in the case of molded articles obtained by the above-mentioned mechanical foaming method, since it is difficult to maintain air bubbles in the reaction mixture solution, the resulting molded article has too high a density and has a problem of low fl...

Embodiment 1

[0080] Add 40 parts by mass of polypropylene glycol (number average molecular weight 6000, trifunctional) purchased from Asahi Glass Co., Ltd. under the trade name "Preminol 7001" and 60 parts by mass of purchased from Asahi Glass Co., Ltd. under the trade name "Preminol 7001" in the reaction vessel. Excenol 3020 "polypropylene glycol (number average molecular weight 3000, bifunctionality), and stirring dehydration under reduced pressure 1 hour. Then, the inside of the reaction vessel was replaced with nitrogen. Then, 10 parts by mass of diphenylmethane diisocyanate purchased from Japan Polyurethane Industry Co., Ltd. under the trade name "MillionateMT" was added to the reaction vessel, and the temperature in the reaction vessel was kept at 80° C., allowing it to react for 5 hours to synthesize Urethane prepolymer A containing isocyanate groups.

[0081] Then, as shown in Table 1 below, by adding 46.2 parts by mass of polypropylene glycol (number-average molecular weight of 6...

Embodiment 2

[0084] A magnetic urethane resin foam was prepared in the same manner as in Example 1 except that the above-mentioned primary stirring time was 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com