Protector with sensor and method of molding end part of the same

一种防护装置、传感器的技术,应用在密封装置、测量装置、测量装置外壳等方向,能够解决电路短路、安装到模具上的作业困难、粘接不良等问题,达到稳定密封性能、缩短作业时间、作业容易的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

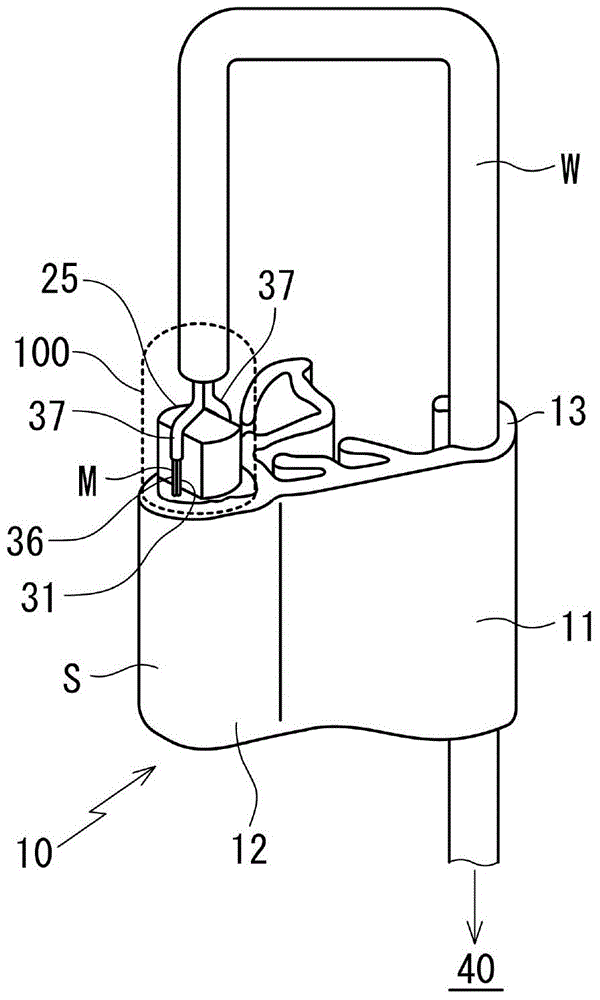

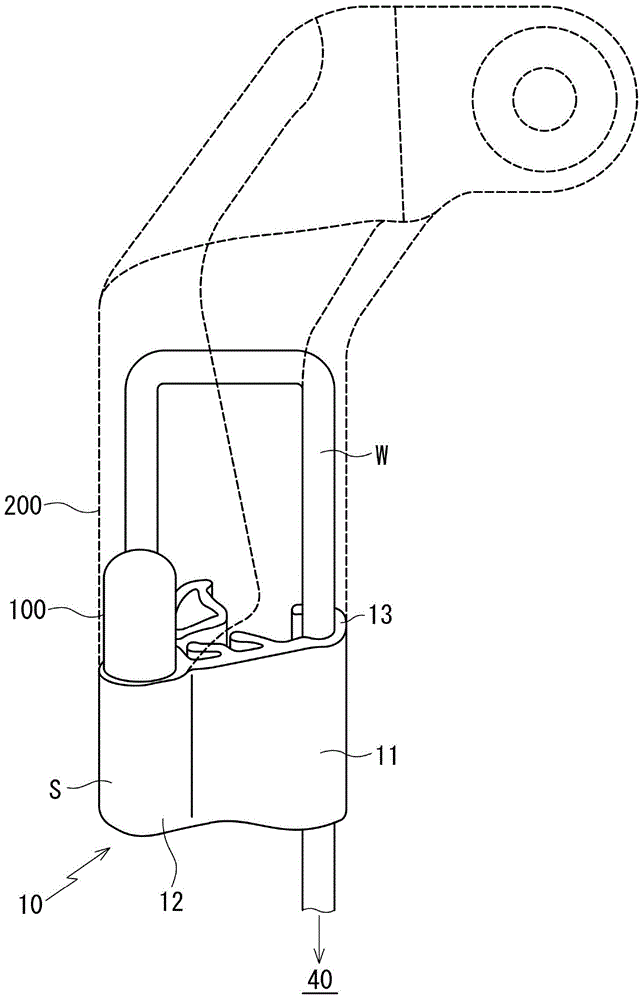

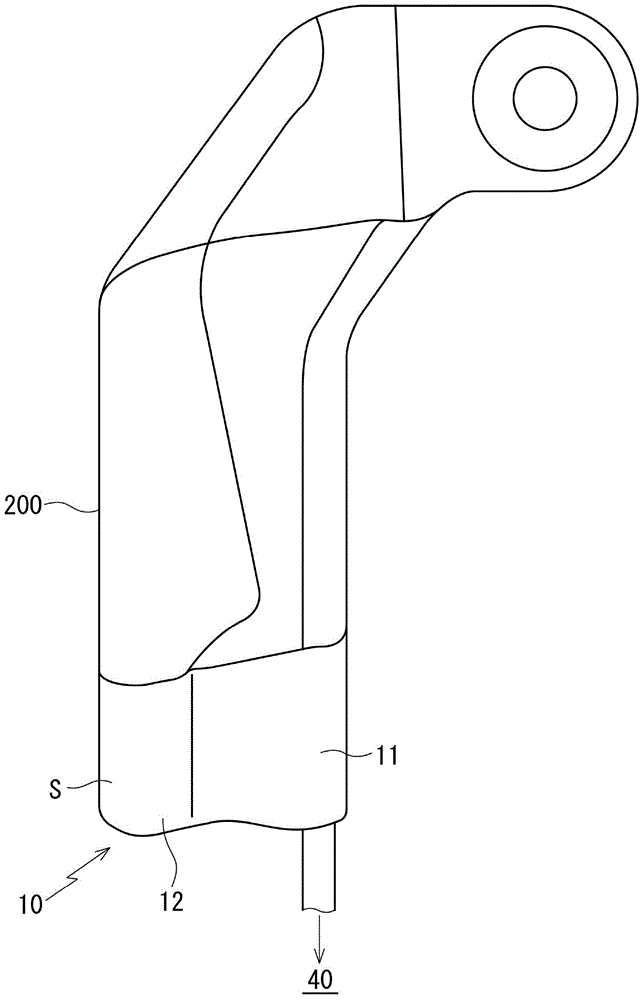

[0077] With reference to the drawings, the protective device with sensor according to the embodiment of the present invention will be described.

[0078] The protective device 10 with a sensor according to the embodiment of the present invention is installed in the Figure 5 The front end surface of the sliding door 1 on a car that opens and closes the opening of the car body as shown in the sliding door 1 and protrudes toward the front side of the car body, the guard 10 is equipped with a sensor (pressure sensitive sensor) S, which The sensor (pressure sensitive sensor) S detects a part of the human body (fingers, hands and feet) and other foreign objects between the sliding door 1 and the opening on the vehicle body side (there is also a front door (side door)). Output the corresponding electronic signal, in Figure 7 to Figure 10 Although the part shown has the same structure as the part shown in the previous example, the structure of the terminal part of the protective device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com