Aluminum silicate fiber reinforced oxide ceramic and preparation method thereof

A technology of aluminum silicate fiber and oxide ceramic, which is applied in the field of aluminum silicate fiber reinforced oxide ceramic and its preparation, can solve problems such as inability to form three-dimensional components, and achieve excellent oxidation resistance, high process efficiency and high specific strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

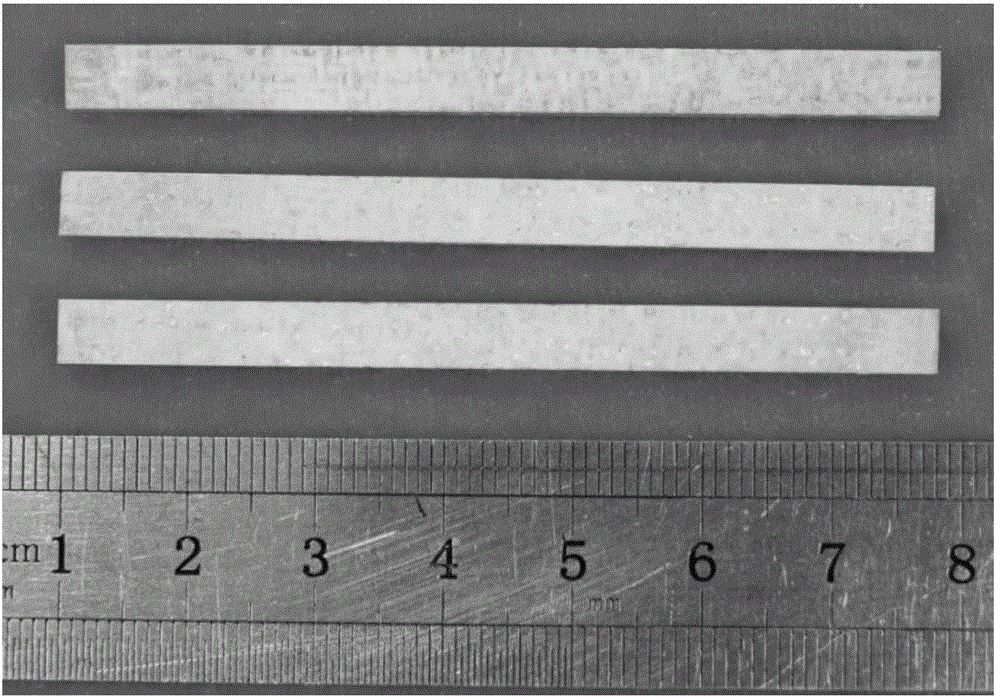

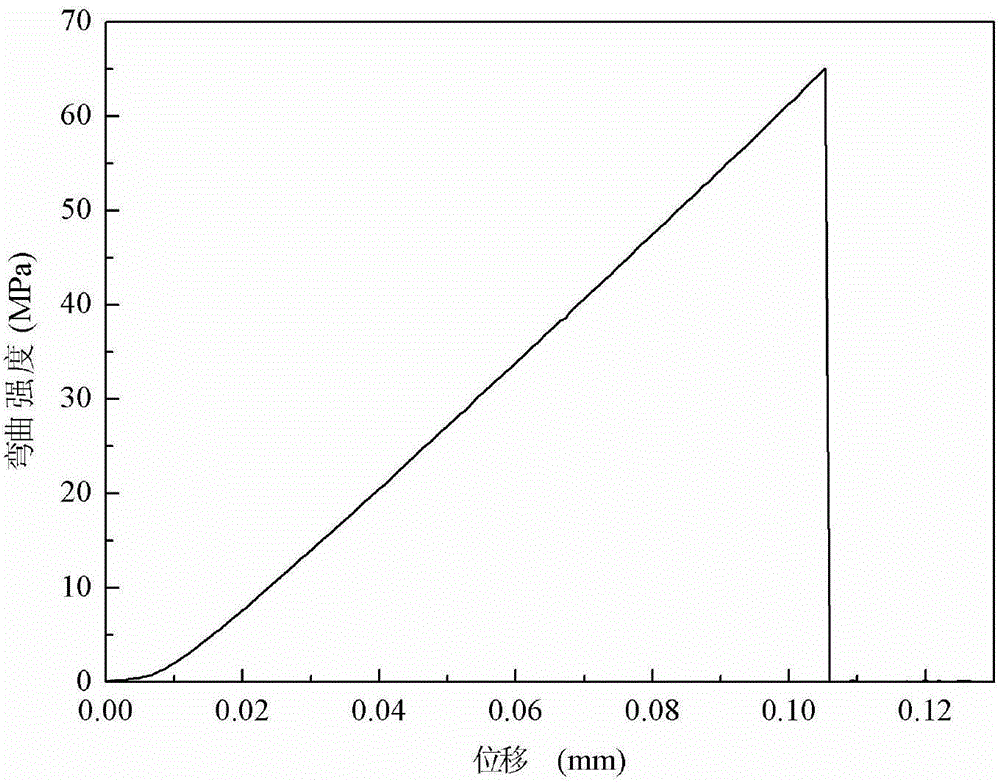

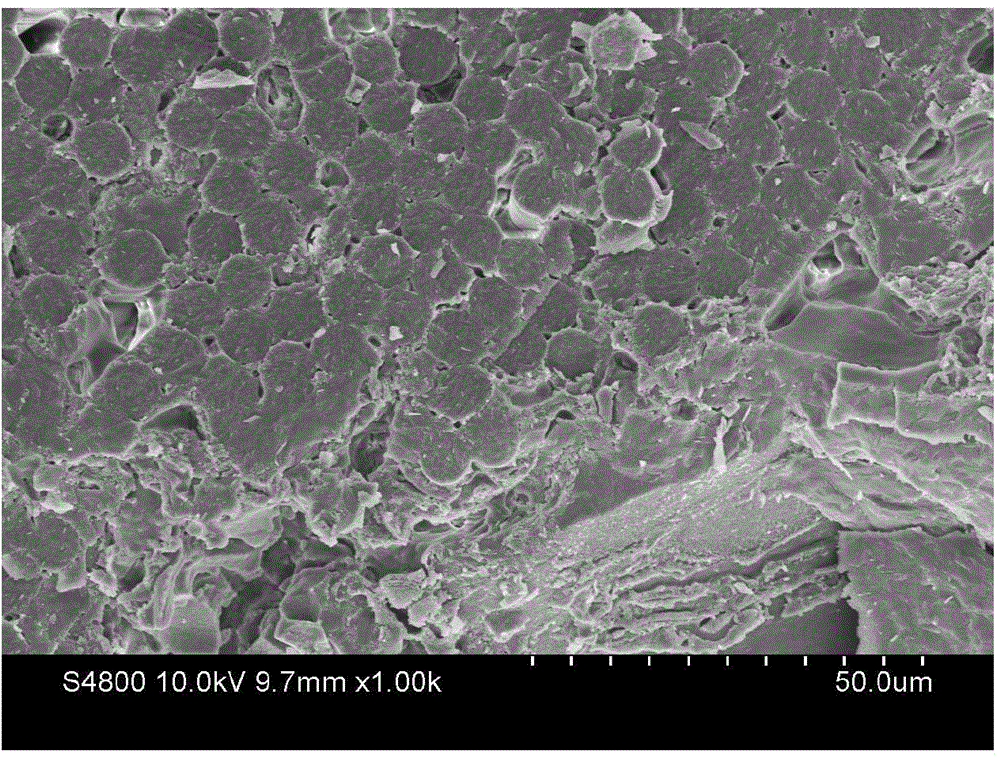

[0037] a kind of like figure 1The aluminum silicate fiber-reinforced mullite ceramics shown in the present invention use mullite as a ceramic matrix, and the reinforcing phase is aluminum silicate fibers.

[0038] A method for preparing the above-mentioned aluminum silicate fiber reinforced mullite ceramics, specifically comprising the following steps:

[0039] (1) Pretreatment of aluminum silicate fiber fabric: place the three-dimensional orthogonal aluminum silicate fiber fabric with a fiber volume fraction of 40% in a muffle furnace, and raise the temperature to 600°C in air at a rate of 10°C / min , keep warm for 1 hour, cool naturally to room temperature and take out;

[0040] (2) Primary densification of the matrix: first, using mullite sol as a precursor, vacuum impregnate the aluminum silicate fiber fabric obtained in step (1) for 6 hours, take it out and let it dry in the air for 2 hours; then, vacuum-impregnate the aluminum silicate fiber fabric Put the final aluminu...

Embodiment 2

[0048] An aluminum silicate fiber-reinforced alumina ceramic of the present invention uses alumina as a ceramic matrix, and the reinforcing phase is aluminum silicate fiber.

[0049] A method for preparing the above-mentioned aluminum silicate fiber reinforced alumina ceramics, specifically comprising the following steps:

[0050] (1) Pretreatment of aluminum silicate fiber fabric: the three-dimensional four-way aluminum silicate fiber fabric with a fiber volume fraction of 45% is placed in a muffle furnace, and the temperature rises to 550 °C in air at a rate of 8 °C / min , keep warm for 1.5h, cool down to room temperature naturally, take out for later use;

[0051] (2) Primary densification of the matrix: first, use alumina sol as a precursor, vacuum impregnate the aluminum silicate fiber fabric obtained in step (1) for 7 hours, take it out and let it dry in the air for 1.5 hours; then, vacuum-impregnate the aluminum silicate fiber fabric Put the final aluminum silicate fibe...

Embodiment 3

[0057] An aluminum silicate fiber-reinforced silica ceramic of the present invention uses silicon oxide as a ceramic matrix, and the reinforcing phase is aluminum silicate fiber.

[0058] A method for preparing the above-mentioned aluminum silicate fiber reinforced silica ceramics, specifically comprising the following steps:

[0059] (1) Pretreatment of aluminum silicate fiber fabric: the three-dimensional orthogonal aluminum silicate fiber fabric with a fiber volume fraction of 42% is placed in a muffle furnace, and the temperature is raised to 520 °C in air at a rate of 6 °C / min , keep warm for 2 hours, cool down to room temperature naturally, take out for later use;

[0060] (2) Primary densification of the matrix: first, using silica sol as a precursor, vacuum-impregnate the aluminum silicate fiber fabric obtained in step (1) for 8 hours, take it out and let it air in the air for 1 hour; then, vacuum-impregnate the aluminum silicate fiber fabric Put the aluminum silicate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com