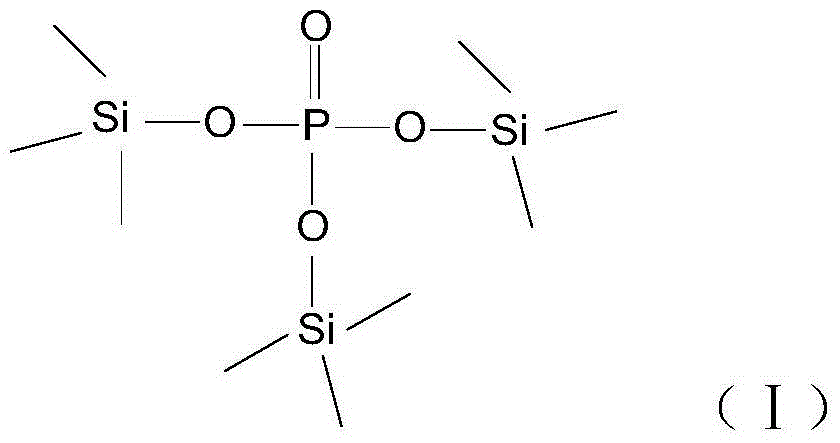

Preparation method of tris(trimethylsilyl)phosphate ester

A technology of trimethylsilyl, phosphate ester, applied in the direction of phosphorus organic compounds, etc., can solve the problems of high reaction temperature, large dosage, and high production cost, and achieve the effects of reducing reaction temperature, improving product yield, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In a 500mL three-necked flask equipped with an electric stirrer, a reflux condenser, and a thermometer, add 115g of ammonium dihydrogen phosphate, 255g of hexamethyldisilazane, and 3.7g of tetrabutylammonium bromide, and stir at 78°C for 3 Hours, the reaction process was carried out under nitrogen protection. After the reaction, filter to obtain the filtrate crude product of tris(trimethylsilyl) phosphate; then carry out vacuum distillation on the filtrate, collect the fraction at 126~128°C / 30mmHg to obtain 285g of tris(trimethylsilyl)phosphate . Based on hexamethyldisilazane, the molar yield is 86.1%.

Embodiment 2

[0023] In a 1000mL three-necked flask equipped with an electric stirrer, a reflux condenser, and a thermometer, add 230g of ammonium dihydrogen phosphate, 520g of hexamethyldisilazane, and 7.5g of dodecyltrimethylammonium chloride. The reaction was stirred for 5 hours, and the reaction process was carried out under the protection of nitrogen. After the reaction, filter to obtain the crude filtrate tris(trimethylsilyl) phosphate; then carry out vacuum distillation on the filtrate, collect the fraction at 126~128°C / 30mmHg to obtain 580g of tris(trimethylsilyl)phosphate . Based on hexamethyldisilazane, the molar yield is 85.8%.

Embodiment 3

[0025] In a 2000mL three-necked flask equipped with an electric stirrer, a reflux condenser, and a thermometer, add 460g of ammonium dihydrogen phosphate, 1040g of hexamethyldisilazane, and 45g of trioctylmethylammonium bromide, and stir the reaction at 68°C After 4 hours, the reaction process was carried out under the protection of argon. After the reaction, filter to obtain the crude filtrate tris(trimethylsilyl) phosphate; then carry out vacuum distillation on the filtrate, collect the fraction at 126~128°C / 30mmHg to obtain 1175g of tris(trimethylsilyl)phosphate . Based on hexamethyldisilazane, the molar yield is 86.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com