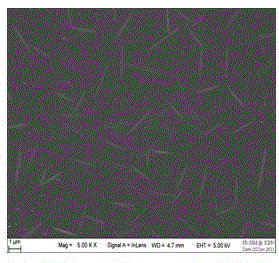

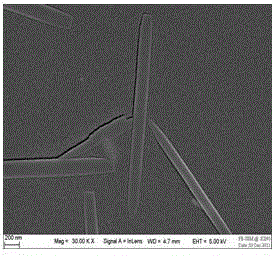

Self-assembly preparation method of gas-liquid interface of silver nanowire/graphene polymer composite film

A technology of silver nanowires and composite films, applied in the field of chemistry, can solve the problems of high conductivity recovery of graphene, and achieve the effects of being suitable for large-scale promotion, improving solubility, and increasing loading capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Graphene oxide colloid (GO, 4mg / ml) was prepared by Hummers method;

[0016] (2) Mix the same volume and concentration (5ml, 0.1M) of sodium citrate aqueous solution and silver nitrate water-DMF solution (V / V=1:1) in a three-necked flask, as solution A. Add 12.96ml polydiallyldimethylammonium chloride (PDDA) modified graphene oxide aqueous solution 54ml (silver:graphene oxide mass ratio is 1:4) as solution B. Sonicate for 30 minutes at room temperature, and then magnetically stir for 12 hours in the dark. Stir magnetically in an oil bath at 130°C for 3h. Then add sodium citrate 2.16g and ascorbic acid 17.28g as the reducing agent of graphene oxide. Graphene oxide was reduced to conductive graphene sheets by ascorbic acid, sodium citrate and polydiallyl dimethyl ammonium chloride at 90°C for 10 hours, and finally washed and centrifuged to prepare 12mg / ml silver nanowires / Graphene hybrid aqueous solution concentration;

[0017] (3) The improved gas-liquid i...

Embodiment 2

[0019] (1) Graphene oxide colloid (GO, 4.5mg / ml) was prepared by Hummers method;

[0020](2) Mix sodium citrate aqueous solution and silver nitrate aqueous-DMF solution (V / V=1:1.2) of the same volume and concentration (5ml, 0.2M) in a three-necked flask and make it as solution A. Add 30.24ml polydiallyldimethylammonium chloride (PDDA) modified graphene oxide aqueous solution 96ml (silver:graphene oxide mass ratio is 1:4) as solution B. Sonicate for 30 min at room temperature, and then magnetically stir for 10 hours in the dark. Then magnetically stir in an oil bath at 130° C. for 3 h. Then add 8.64g sodium citrate and 34.56g ascorbic acid as the reducing agent of graphene oxide. Graphene oxide was reduced to conductive graphene sheets by ascorbic acid, sodium citrate and polydiallyl dimethyl ammonium chloride at 60°C for 7 hours, and finally fully washed and centrifuged to prepare 14mg / ml silver nanosheets. Concentration of wire / graphene hybrid aqueous solution;

[0021] ...

Embodiment 3

[0023] (1) Graphene oxide colloid (GO, 5mg / ml) was prepared by Hummers method;

[0024] (2) Mix sodium citrate aqueous solution and silver nitrate aqueous-DMF solution (V / V=1:1.2) of the same volume and concentration (5ml, 0.3M) in a three-necked flask, as solution A. Add 51.84ml polydiallyldimethylammonium chloride (PDDA) modified graphene oxide aqueous solution 129.6ml (silver:graphene oxide mass ratio is 1:4) as solution B. Sonicate for 30 min at room temperature, and then magnetically stir for 10 hours in the dark. Then magnetically stir in an oil bath at 130° C. for 3 h. Then add 12.96g sodium citrate and 58.32g ascorbic acid as the reducing agent of graphene oxide. Graphene oxide was reduced to conductive graphene sheets by ascorbic acid, sodium citrate and polydiallyl dimethyl ammonium chloride at 70°C for 8 hours, and finally fully washed and centrifuged to prepare 15mg / ml silver nanosheets. Concentration of wire / graphene hybrid aqueous solution;

[0025] (3) The i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com