Epoxy resin toughening agent based on cyclotriphosphazene six-arm star polymer and preparation method for epoxy resin toughening agent

A technology of star-shaped polymer and cyclotriphosphazene is applied in the field of epoxy resin toughening agent. problem, to achieve the effect of good compatibility, improved toughness and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

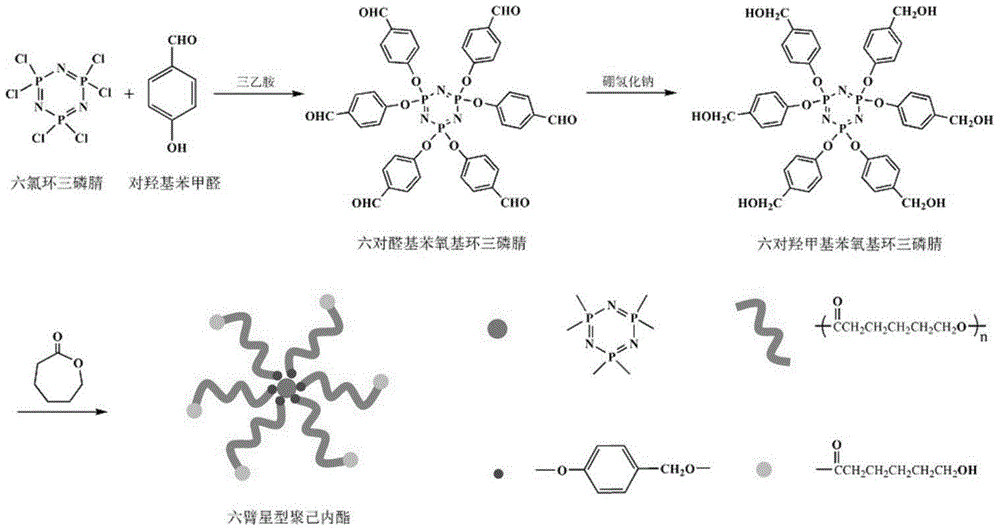

[0023] Add 14.76 g of p-hydroxybenzaldehyde and 50 mL of tetrahydrofuran, and then add 20 mL of triethylamine (TEA) into a 250 mL dry three-necked flask equipped with a magnet, a thermometer, a constant pressure dropping funnel, and a condensing reflux device. After heating to 60°C, a solution of 6.95 g of hexachlorocyclotriphosphazene in tetrahydrofuran (40 mL) was added dropwise with stirring, and the reaction was refluxed for 8 hours while stirring. Hexa(p-aldehydephenoxy)cyclotriphosphazene was obtained after recrystallization from ethyl acetate.

[0024] Into a 250 mL three-necked flask, 4.31 g of hexa(p-formylphenoxy)cyclotriphosphazene, 30 mL of tetrahydrofuran, and 15 mL of methanol were sequentially added, and stirred evenly. Add 2g of sodium borohydride and react at 25°C for 14h. After the solvent was removed by rotary evaporation, it was washed with water and recrystallized twice in ethanol to obtain hexa(p-hydroxymethylphenoxy)cyclotriphosphazene.

[0025] Add 6....

Embodiment 2

[0033] Add 14.76 g of p-hydroxybenzaldehyde and 50 mL of tetrahydrofuran, and then add 20 mL of triethylamine (TEA) into a 250 mL dry three-necked flask equipped with a magnet, a thermometer, a constant pressure dropping funnel, and a condensing reflux device. After heating to 60°C, a solution of 6.95 g of hexachlorocyclotriphosphazene in tetrahydrofuran (40 mL) was added dropwise with stirring, and the reaction was refluxed for 8 hours while stirring. Hexa(p-aldehydephenoxy)cyclotriphosphazene was obtained after recrystallization from ethyl acetate.

[0034] Into a 250 mL three-necked flask, 4.31 g of hexa(p-formylphenoxy)cyclotriphosphazene, 30 mL of tetrahydrofuran, and 15 mL of methanol were sequentially added, and stirred evenly. Add 2g of sodium borohydride and react at 25°C for 14h. After the solvent was removed by rotary evaporation, it was washed with water and recrystallized twice in ethanol to obtain hexa(p-hydroxymethylphenoxy)cyclotriphosphazene.

[0035] Add 6....

Embodiment 3

[0038] Add 14.76 g of p-hydroxybenzaldehyde and 50 mL of tetrahydrofuran, and then add 20 mL of triethylamine (TEA) into a 250 mL dry three-necked flask equipped with a magnet, a thermometer, a constant pressure dropping funnel, and a condensing reflux device. After heating to 60°C, a solution of 6.95 g of hexachlorocyclotriphosphazene in tetrahydrofuran (40 mL) was added dropwise with stirring, and the reaction was refluxed for 8 hours while stirring. Hexa(p-aldehydephenoxy)cyclotriphosphazene was obtained after recrystallization from ethyl acetate.

[0039] Into a 250 mL three-necked flask, 4.31 g of hexa(p-formylphenoxy)cyclotriphosphazene, 30 mL of tetrahydrofuran, and 15 mL of methanol were sequentially added, and stirred evenly. Add 2g of sodium borohydride and react at 25°C for 14h. After the solvent was removed by rotary evaporation, it was washed with water and recrystallized twice in ethanol to obtain hexa(p-hydroxymethylphenoxy)cyclotriphosphazene.

[0040] Add 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com