Turbocharger integral type bearing with locating mechanism

A technology of turbocharger and positioning mechanism, which is applied in the directions of bearings, bearings and bearing components in rotating motion, and achieves the effects of convenient production and manufacturing quality control, simple structure and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

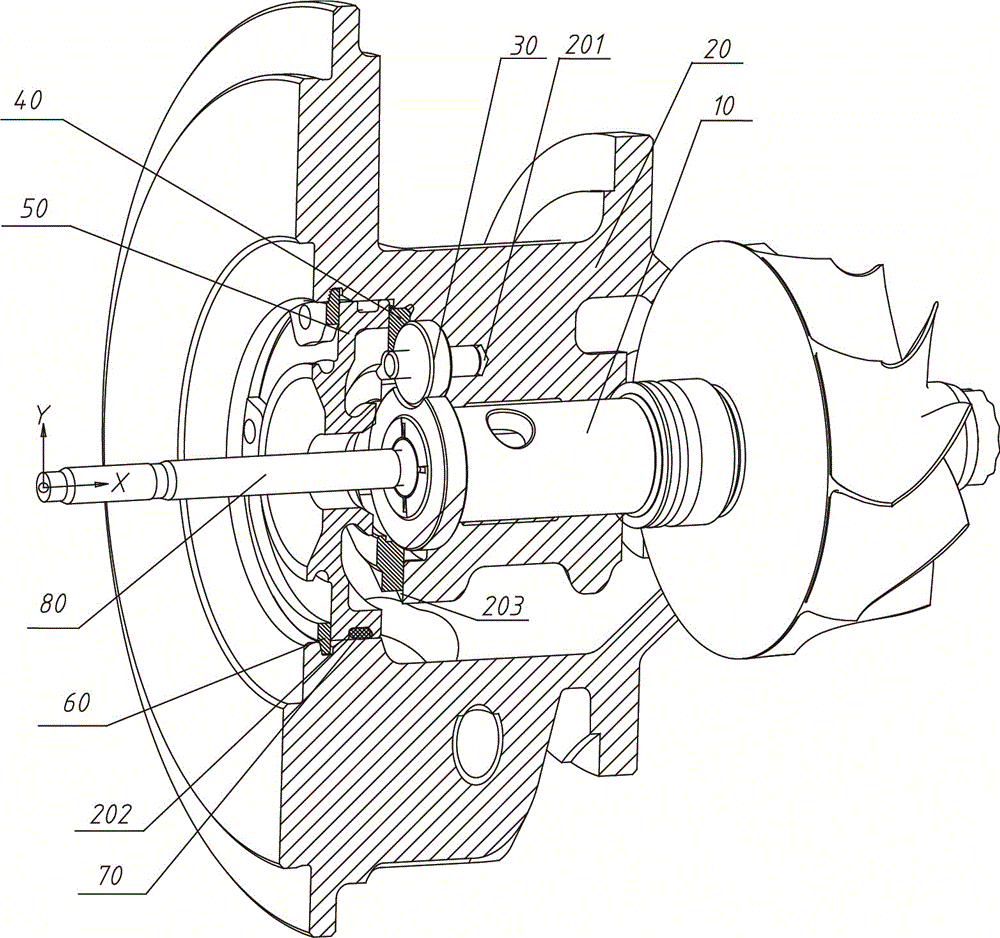

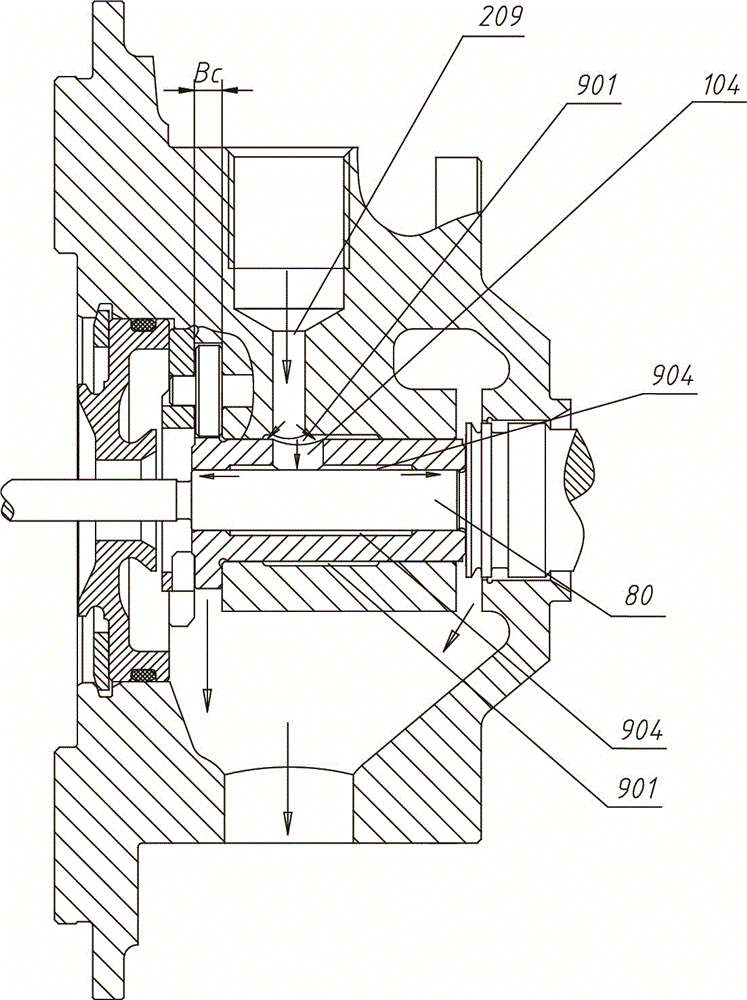

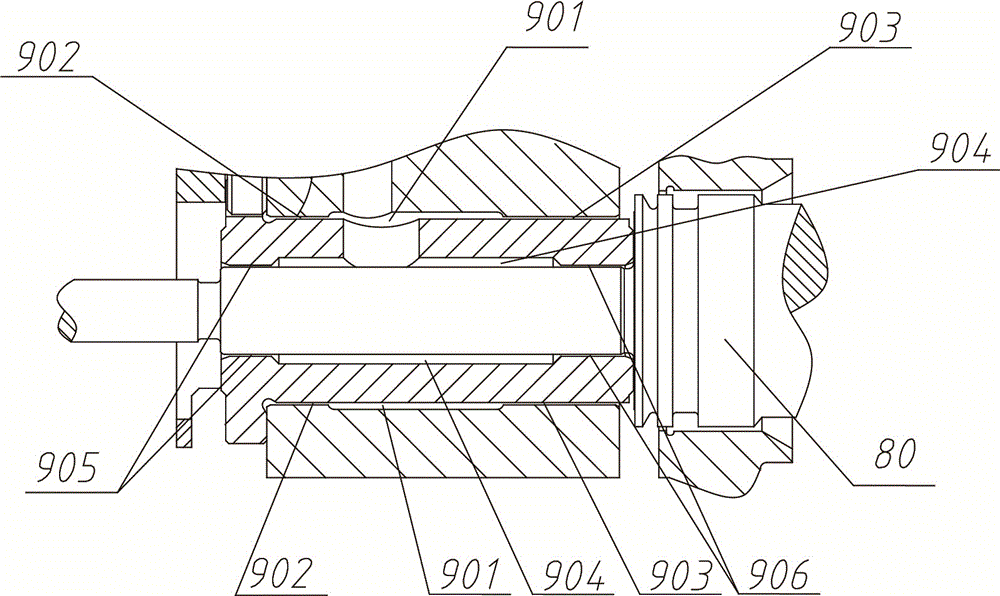

[0033] See Figure 1 to Figure 10 , a turbocharger integral bearing with a positioning mechanism, comprising an integral bearing 10 provided with an oil hole 104, and a positioning mechanism that cooperates with the integral bearing 10, and one end of the integral bearing 10 facing the positioning mechanism is provided with Shaft shoulder 105, said shaft shoulder 105 is provided with gap 103, and said gap 103 is an arc-shaped gap; said positioning mechanism includes positioning pin 30, a thrust plate 40 for limiting the lateral movement of integral bearing 10, located on The oil seal cover 50 on the outside of the thrust plate 40, the positioning pin 30 is provided with a disk 301 that can partially enter the arc-shaped gap; the thrust plate 40 is provided with a hole 403 for the positioning pin 30 to insert ; The oil seal cap 50 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com