Flue gas waste heat recovery system and recovery method and application thereof

A flue gas waste heat recovery system technology, applied in the field of flue gas waste heat recovery, can solve problems such as cost increase, achieve the effect of improving efficiency, improving heat utilization value and economic benefits, and optimizing heat utilization methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

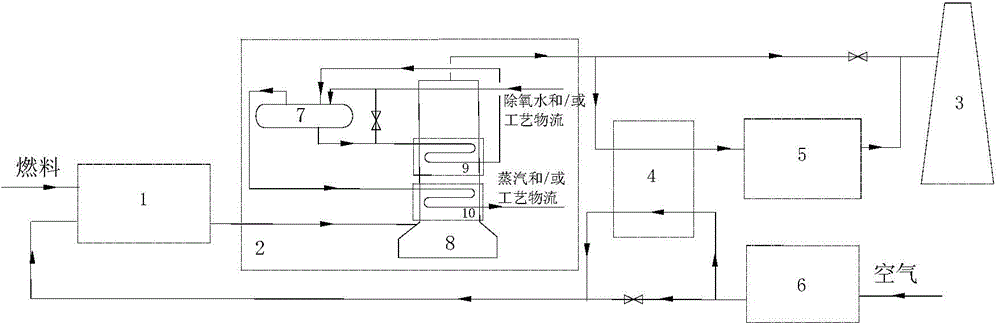

Embodiment 1

[0036] This embodiment adopts figure 1 The system shown performs flue gas waste heat recovery. Fuel and air heated by the air preheater 4 from the blower 6 enter the heating furnace radiant chamber 1, and the flue gas leaving the heating furnace radiant chamber 1 is the flue gas in the convection chamber 2 of the heating furnace The inlet enters the furnace body 8, and the material is directly added to the material inlet of the steam drum 7. A part of the liquid in the steam drum 7 enters the evaporation section 9 from the downcomer of the steam drum 7 to be heated to produce steam, and part of the liquid material becomes steam to form a gas-liquid mixture , The gas-liquid mixture leaves the evaporation section 9 and enters the steam drum 7, where the gas-liquid separation is carried out in the steam drum 7, and the liquid falls into the liquid space in the steam drum 7; the other part of the liquid in the steam drum 7 is connected to the material inlet of the steam drum 7 After...

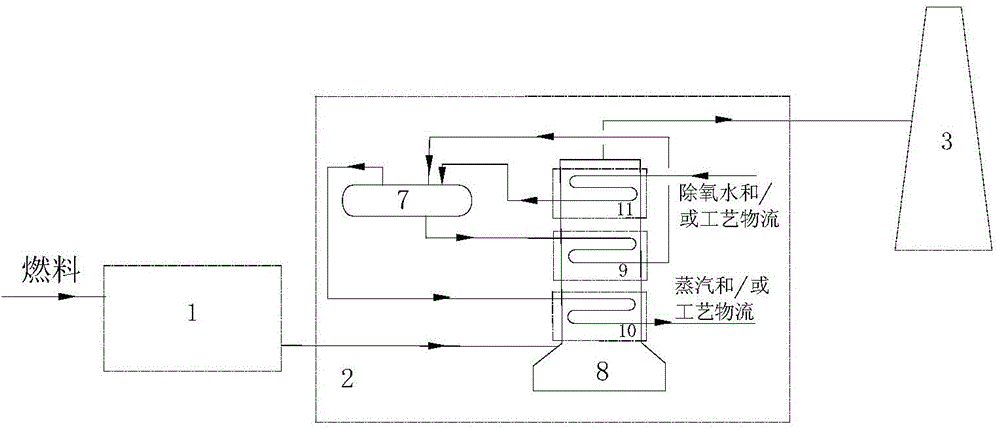

Embodiment 2

[0039] Except that the coal-saving section 11 in the convection chamber 2 of the heating furnace is drawn out while one furnace tube in the evaporation section 9 in the convection chamber 2 of the heating furnace is drawn out, the other processes are the same as in Embodiment 1.

[0040] It increases the temperature of the flue gas at the outlet of the convection chamber 2 of the heating furnace to 250-350°C, thereby effectively increasing the temperature of the air entering the radiation chamber of the heating furnace, and finally achieves the purpose of rationally optimizing the heat energy distribution of the flue gas and reducing the fuel consumption of the heating furnace.

Embodiment 3

[0042] Except that the coal-saving section 11 in the convection chamber 2 of the heating furnace is drawn out while three furnace tubes in the evaporation section 9 in the convection chamber 2 of the heating furnace are drawn out, the other processes are the same as in Embodiment 1.

[0043] It increases the temperature of the flue gas at the outlet of the convection chamber 2 of the heating furnace to 250-350°C, thereby effectively increasing the temperature of the air entering the radiation chamber of the heating furnace, and finally achieves the purpose of rationally optimizing the heat energy distribution of the flue gas and reducing the fuel consumption of the heating furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com