Organic electroluminescent light emitting device and preparation method thereof

An electroluminescent device and electroluminescent technology, which are applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of reducing luminous efficiency, adverse effects on device life, etc., so as to improve luminous efficiency and improve luminous efficiency. , the effect of strong reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

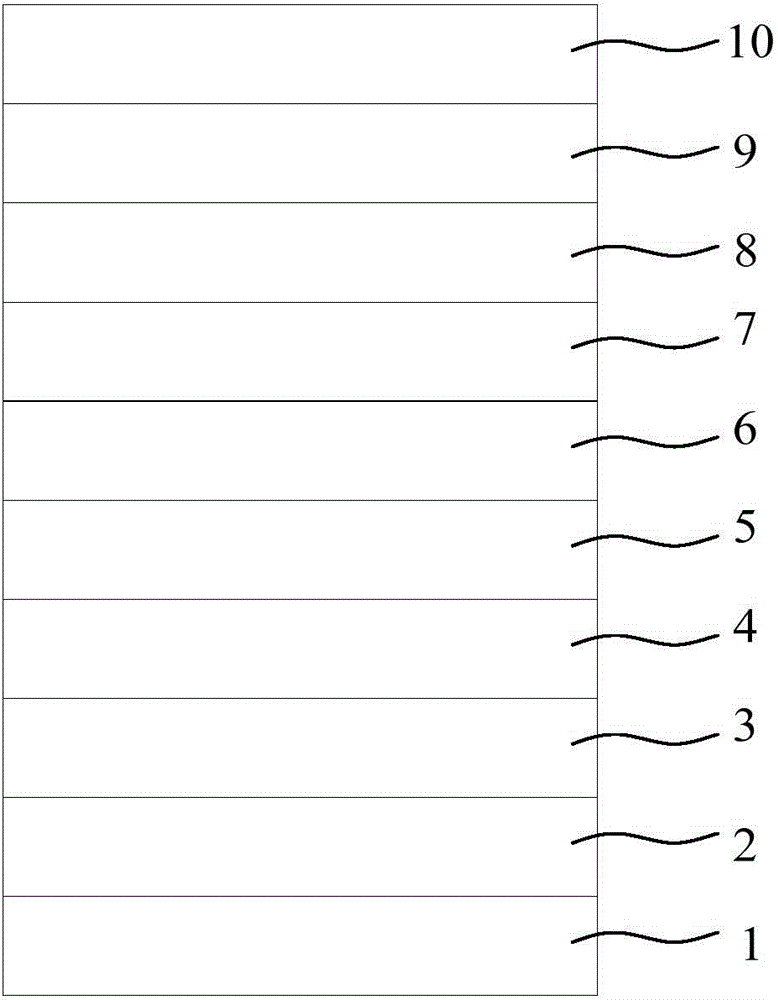

[0054] A method for preparing an organic electroluminescent device, comprising the following steps:

[0055] (1) Rinse the commercially available common glass substrate with distilled water and ethanol, and soak it in isopropanol for one night. The anode 2 is prepared on the glass substrate 1 by magnetron sputtering. The material of the anode 2 is ITO, the thickness is 110nm, the acceleration voltage of the magnetron sputtering is 700V, the magnetic field is about 120G, and the power density is 25W / cm 2 ; Then on the anode 2, the thermal resistance evaporation hole injection layer 3 and the hole transport layer 4 are sequentially deposited; wherein the material of the hole injection layer is MoO 3 , the thickness is 33nm, and the pressure used in evaporation is 8×10 -4 Pa, the evaporation rate is 2nm / s; the material of the hole transport layer is NPB, the thickness is 50nm, and the pressure used in the evaporation is 8×10 -4 Pa, the evaporation rate is 0.2nm / s;

[0056] (2)...

Embodiment 2

[0063] A method for preparing an organic electroluminescent device, comprising the following steps:

[0064] (1) Rinse the commercially available common glass substrate with distilled water and ethanol, and soak it in isopropanol for one night. The anode is prepared on the glass substrate by magnetron sputtering. The material of the anode is AZO, the thickness is 300nm, the acceleration voltage of magnetron sputtering is 300V, the magnetic field is about 50G, and the power density is 40W / cm 2 ; Then on the anode, the thermal resistance evaporation hole injection layer and the hole transport layer are sequentially deposited; wherein the material of the hole injection layer is V 2 o 5 , the thickness is 20nm, and the pressure used in evaporation is 2×10 -3 Pa, the evaporation rate is 10nm / s; the material of the hole transport layer is TCTA, the thickness is 50nm, and the pressure used in the evaporation is 2×10 -3 Pa, the evaporation rate is 1nm / s;

[0065] (2) On the hole t...

Embodiment 3

[0072] A method for preparing an organic electroluminescent device, comprising the following steps:

[0073] (1) Rinse the commercially available common glass substrate with distilled water and ethanol, and soak it in isopropanol for one night. The anode is prepared on the glass substrate by magnetron sputtering. The material of the anode is IZO, the thickness is 150nm, the acceleration voltage of magnetron sputtering is 800V, the magnetic field is about 200G, and the power density is 1W / cm 2 ; Then on the anode, the thermal resistance evaporation hole injection layer and the hole transport layer are sequentially deposited; wherein the material of the hole injection layer is V 2 o 5 , the thickness is 55nm, and the pressure used in evaporation is 5×10 -5 Pa, the evaporation rate is 1nm / s; the material of the hole transport layer is TAPC, the thickness is 60nm, and the pressure used in the evaporation is 5×10 -5 Pa, the evaporation rate is 0.1nm / s;

[0074] (2) On the hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com