Organic electroluminescent light emitting device and preparation method thereof

An electroluminescent device and luminescent technology, which is applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of reduced luminous efficiency and low probability of exciton recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

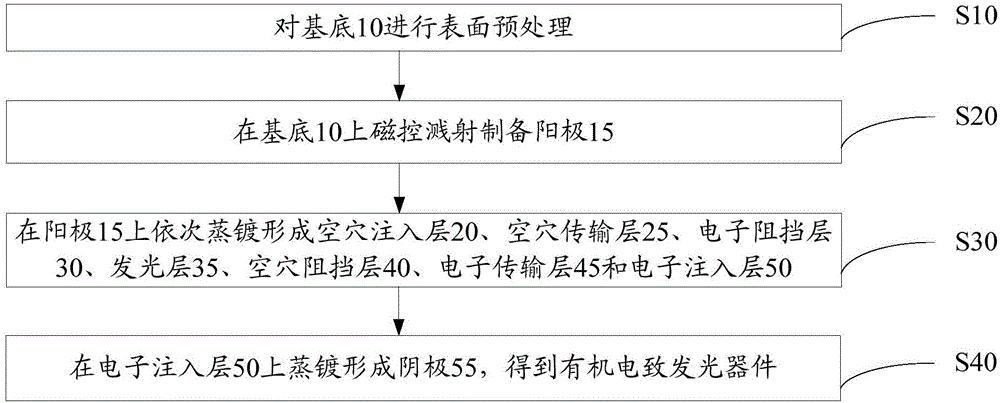

[0051] Such as figure 2 The preparation method of the above-mentioned organic electroluminescence device shown, comprises the following steps:

[0052] S10 , performing surface pretreatment on the substrate 10 .

[0053] The substrate 10 is glass. Generally speaking, ordinary glass will do. In special application fields, special glass made by special process can also be selected.

[0054] The surface pretreatment process specifically includes: after the substrate 10 is rinsed with distilled water and ethanol in sequence, it is soaked in isopropanol overnight.

[0055] S20 , preparing the anode 15 on the substrate 10 by magnetron sputtering.

[0056] The anode 15 can be an indium tin oxide film (ITO), an aluminum-doped zinc oxide film (AZO) or an indium-doped zinc oxide film (IZO), and the thickness of the anode 15 is 50nm-300nm. In a preferred embodiment, the anode 15 is an indium tin oxide film (ITO), and the thickness of the anode 15 is 110 nm.

[0057] The accelerati...

Embodiment 1

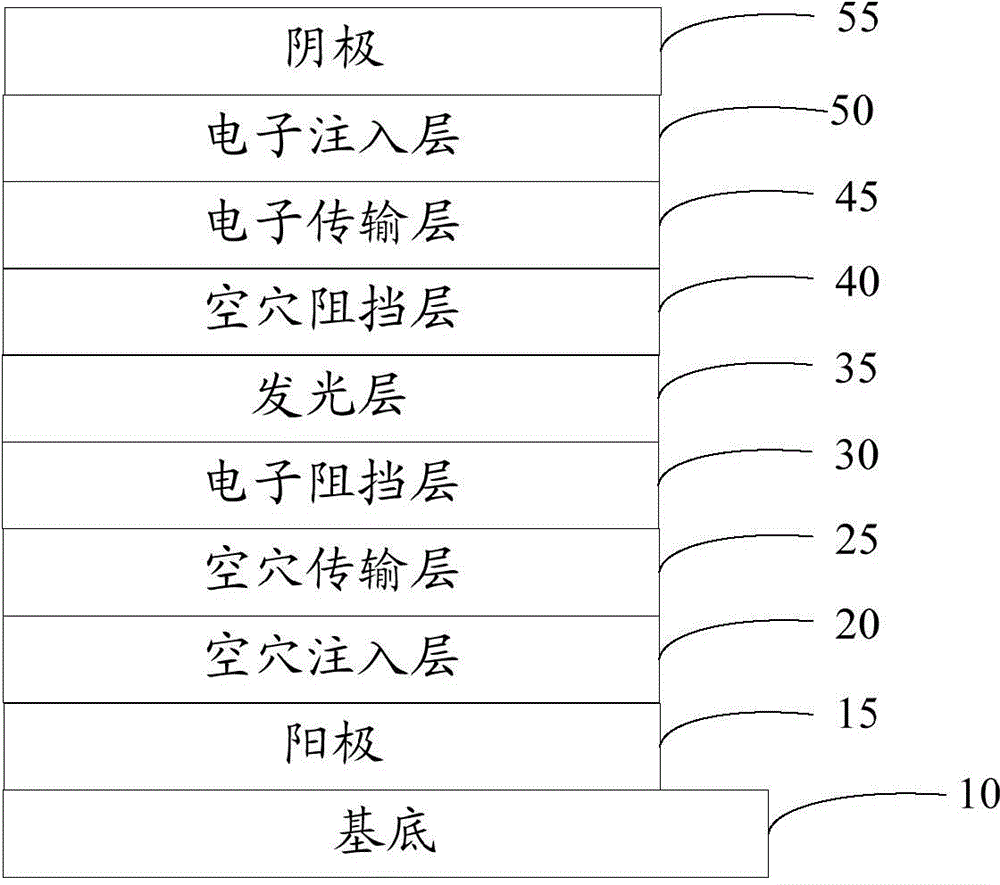

[0080] An organic electroluminescent device, comprising a substrate, an anode, a hole injection layer, a hole transport layer, an electron blocking layer, a light-emitting layer, a hole blocking layer, an electron transport layer, an electron injection layer and a cathode stacked in sequence, the specific structure Expressed as: glass / ITO / MoO 3 / NPB / UGH2: CuPc / Alq 3 / Re 2 o 7 :(Ir(ppy) 3 / TPBI / Cs 2 CO 3 / Ag.

[0081] The preparation steps are:

[0082] Provide a commercially available common glass, rinse the glass with distilled water and ethanol in sequence, and soak it in isopropanol overnight.

[0083] The anode was prepared by magnetron sputtering on the surface-treated glass surface. The material of the anode is ITO, and the thickness is 110nm. The acceleration voltage of magnetron sputtering is 700V, the magnetic field is 120G, and the power density is 25W / cm 2 .

[0084] The working pressure is 8×10 -4 Under the condition of Pa, according to the vapor deposi...

Embodiment 2

[0090] An organic electroluminescent device, comprising a substrate, an anode, a hole injection layer, a hole transport layer, an electron blocking layer, a light-emitting layer, a hole blocking layer, an electron transport layer, an electron injection layer and a cathode stacked in sequence, the specific structure Expressed as: Glass / AZO / V 2 o 5 / NPB / UGH1: ZnPc / BCzVBi / ReO 2 : FIrpi / TAZ / LiF / Pt.

[0091] The preparation steps are:

[0092] Provide a commercially available common glass, rinse the glass with distilled water and ethanol in sequence, and soak it in isopropanol overnight.

[0093] The anode was prepared by magnetron sputtering on the surface-treated glass surface. The material of the anode is AZO with a thickness of 300nm. The acceleration voltage of magnetron sputtering is 300V, the magnetic field is 50G, and the power density is 40W / cm 2 .

[0094] The working pressure is 2×10 -3 Under the condition of Pa, the evaporation rate of organic materials is 1nm / s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com