Preparation method of self-supporting flexible composite electrode material used by lithium ion battery

A lithium-ion battery and composite electrode technology, which is applied in the field of electrode materials and composite electrode materials, can solve the problems of battery capacity drop, low conductivity, etc., and achieve the effect of avoiding capacity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

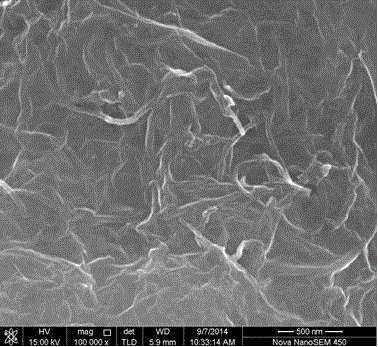

[0023] The self-supporting composite electrode material was prepared by adding graphene oxide / carbon nanotube / metal manganese complex at a mass ratio of 2:1:7, and its electrochemical lithium storage performance was measured. The specific steps are as follows:

[0024] (1) Prepare a 0.6 mg / ml graphene oxide ethanol solution.

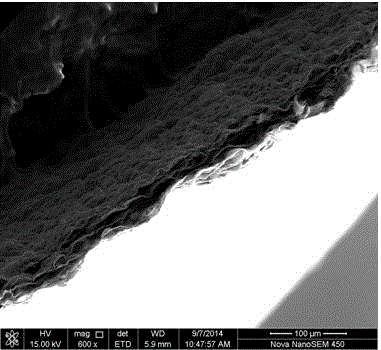

[0025] (2) Take 0.0238g of manganese complex nanofibers into a beaker, add 50mL of ethanol, put it into ultrasonic dispersion for 30min, then stir on a magnetic stirrer for 2h to ensure that the manganese salt is evenly dispersed in the solution, and then take 7.5ml of graphene oxide solution and 18ul of 7.5wt% carbon nanotube aqueous dispersion were added to the beaker, followed by stirring for 2 hours to allow the substances in the solution to be evenly distributed, and then suction-filtered to form a film.

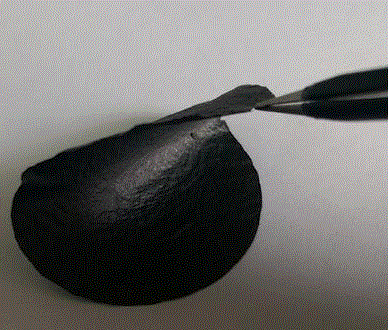

[0026] (3) The film was placed in a laser calciner and calcined with a 2.4 W laser for 5 seconds to prepare a self-supporting flexible composite ...

Embodiment 2

[0029] Prepare the self-supporting composite electrode material by adding graphene carbon nanotubes and manganese salt at a mass ratio of 2:2:6, and measure its electrochemical lithium storage performance. The specific steps are as follows:

[0030] (1) Prepare 0.6 mg / ml graphene oxide isopropanol solution.

[0031] (2) Add 0.0208g of manganese complex nanofibers into a beaker, add 30 ml of ethanol to the beaker, put it into ultrasonic dispersion for 30 minutes, and then stir on a magnetic stirrer for 2 hours to ensure that the manganese salt is evenly dispersed in the solution , and then respectively take 7.5ml of graphene oxide solution and 36 ul of 7.5 wt% carbon nanotube aqueous dispersion into the beaker, then stir for 2 h to allow the substances in the solution to be evenly distributed, and then filter to form a film.

[0032] (3) The film was placed in a laser calciner and calcined with a 2.4 W laser for 10 seconds to prepare a self-supporting flexible composite electro...

Embodiment 3

[0036] Prepare a self-supporting composite electrode material by adding graphene carbon nanotubes and manganese salt at a mass ratio of 2:3:5, and measure its electrochemical lithium storage performance. The specific steps are as follows:

[0037] (1) Prepare a 0.6 mg / ml graphene oxide ethanol solution.

[0038] (2) Add 0.0170g of manganese complex nanofibers into a beaker, add 20 ml of ethanol to the beaker, put it into ultrasonic dispersion for 30min, and then stir on a magnetic stirrer for 1h to ensure that the manganese salt is evenly dispersed in the solution , and then respectively take 7.5ml of graphene oxide solution and 54ul of carbon nanotube aqueous dispersion into the beaker, then stir for 4 hours to allow the substances in the solution to be evenly distributed, and then suction filter to form a film.

[0039] (3) The film was placed in a laser calciner and calcined with a 2.4 W laser for 10 seconds to prepare a self-supporting flexible composite electrode film mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com