Ultrporous nanofiber mats and uses thereof

A nanofiber and fiber technology, applied in the field of liquid filtration media, can solve problems that have not been reported yet, achieve high water flux and reduce the amount of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

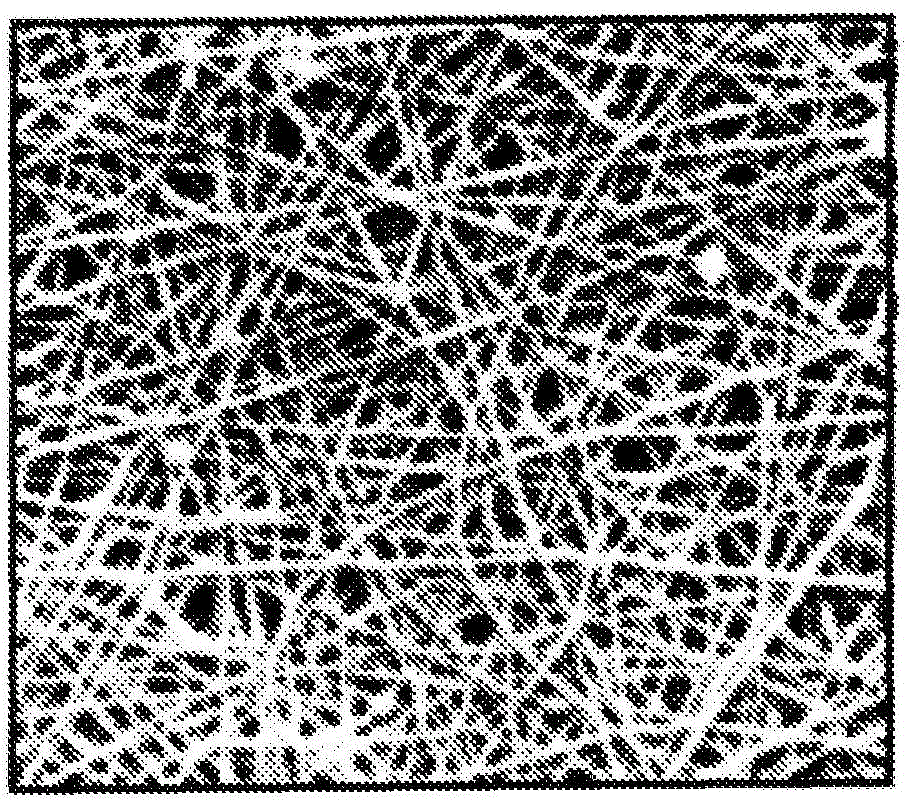

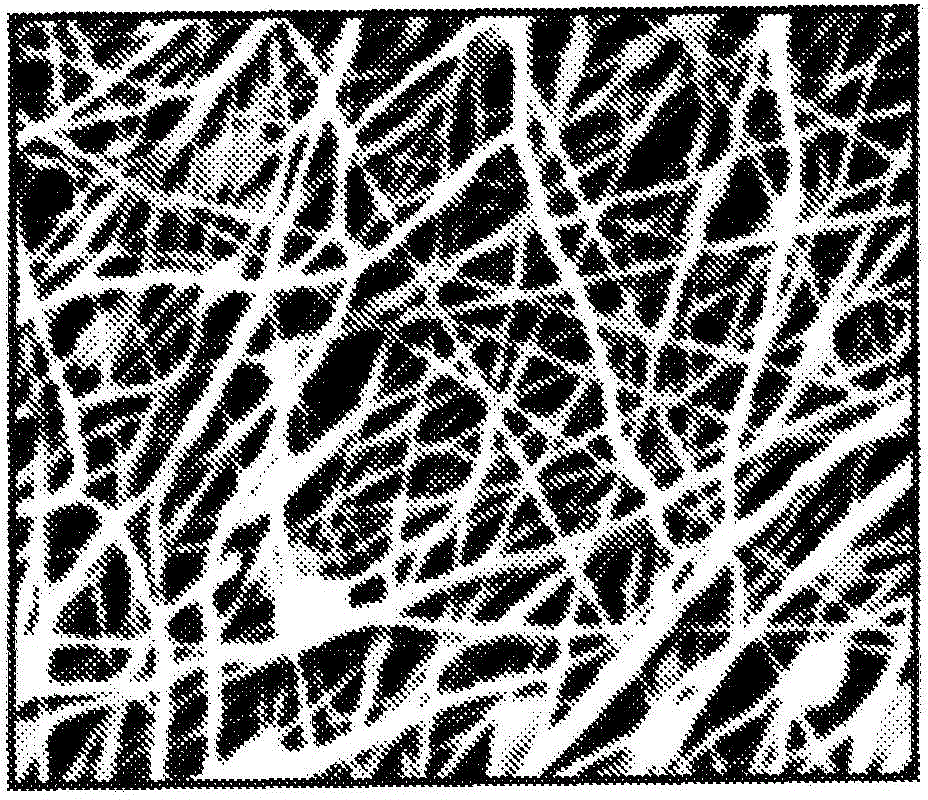

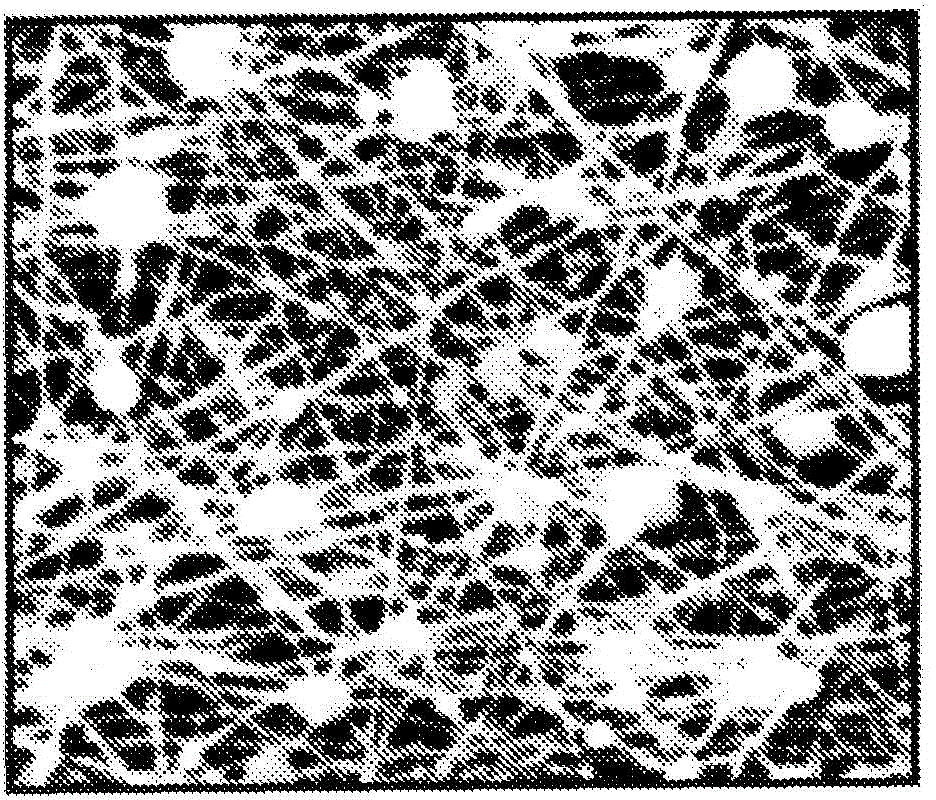

Image

Examples

Embodiment 1

[0111] Example 1. Preparation of Nylon stock solution for electrospinning

[0112] This example provides an exemplary procedure for preparing a nylon solution for electrospinning according to an embodiment of the invention.

[0113] Nylon 6 is supplied by BASF Corporation (Florham Park, NJ, USA) under the trademark Ultramid B24. A 15% wt. solution was prepared from a mixture of three solvents (formic acid, acetic acid and water) present in a weight ratio of 2:2:1. The solutions were prepared by vigorously stirring a mixture of solvent and polymer at 80°C for 5 to 6 hours in a glass reactor. It was then cooled to room temperature. The molecular weight of the final polymer was analyzed by SEC and found to decrease due to heating in this solvent system (Table 1). In addition, the molecular weight distribution (Mw / Mn) also decreased.

[0114] Table 1. Molecular weight analysis of nylon 6 before preparation of stock solutions and as a result of hydrolysis.

[0115]

[0116]...

Embodiment 2

[0117] Example 2. Preparation of Nylon Solutions Ready for Electrospinning According to Embodiments of the Invention.

[0118] The stock solution prepared in Example 1 was diluted to 8% wt. polymer with 2,2,2-trifluoroethanol (TFE), formic acid and water. Ammonium formate was added to a concentration of 1% wt. The composition of the spinning solution is listed in Table 2.

[0119] Table 2. Composition of the spinning solution.

[0120]

[0121] The viscosity of the final solution at 25°C was 30 cP to 35 cP, and the conductivity was 1.0 mS / cm to 1.5 mS / cm.

Embodiment 3

[0122] Example 3. Preparation of Parvovirus Retention Pads According to Embodiments of the Invention.

[0123] Nanospider purchased from Elmarco (Morrisville, NC USA) was used immediately TM The solution from Example 2 was spun by a nozzleless electrospinning device. The 6-wire rotating electrode is equipped with 33-gauge steel wire, the distance between the solution pan (pan) and the collector is 140mm, the electrode rotation speed is 60Hz, and the humidity is maintained between 10° dew point and 16° dew point using an external humidification system . The spinning time was 30 min. In this embodiment, the support material used to collect the nanofibers was also an electrospun nylon 6 mat with an average fiber diameter of about 100 nm. In this embodiment, the supportive electrospun material was prepared from a 12 wt. Nylon 6 is produced by electrospinning, and the weight ratio between the acids is 2:1.

[0124] Table 3 summarizes the properties of the fabricated electrospu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com