Low-temperature self-welding method of carbon-coating copper nanowires

A copper nanowire, carbon coating technology, applied in welding equipment, metal processing equipment, manufacturing tools and other directions, can solve the problems of low working temperature and low solder utilization rate, and achieve high utilization rate of copper atoms, large flow rate adjustment range, and high working efficiency. low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further introduced below in conjunction with the accompanying drawings and specific implementation methods.

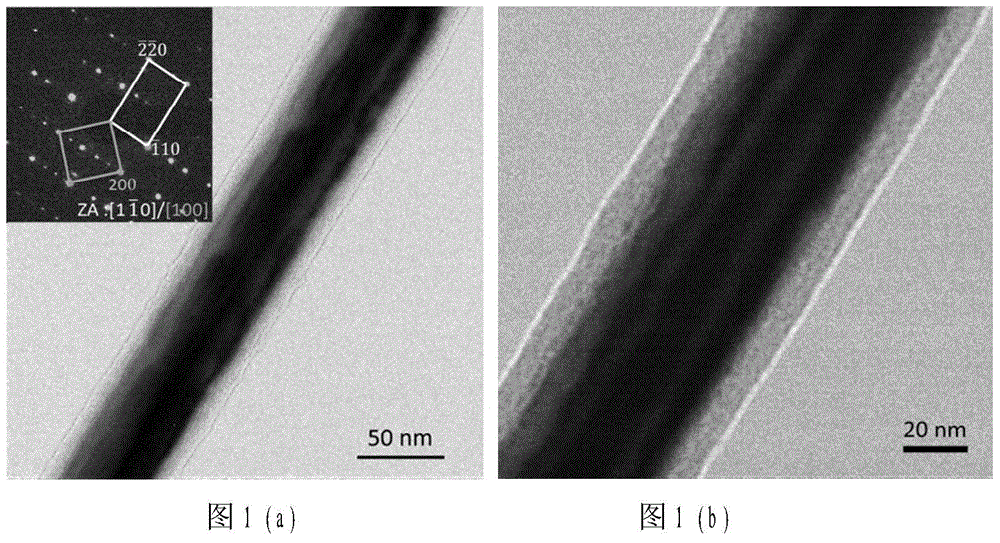

[0021] attached figure 1 It is a transmission electron microscope photo of copper nanowires coated with amorphous carbon shells on the surface synthesized by hydrothermal method in the present invention: figure 1 (a) is a photo of the nanowire at a lower magnification, and the diffraction spot proves the five-time twinning structure of the copper nanowire, figure 1 (b) is a high-resolution electron micrograph of the nanowires. It can be seen that the surface of the copper nanowires is covered by an amorphous shell. The details of the synthesis process of the whole copper nanowires are as follows:

[0022] Add 21 mg of copper chloride and 49 mg of glucose into 10 mL of deionized water in sequence, then add 180 mg of surfactant octadecylamine, and mix thoroughly for 5 hours with magnetic stirring; then transfer the solution to a 25 mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com