A solid flux for stainless steel soldering

A flux and soldering technology, which is applied in welding medium, welding equipment, welding/cutting medium/material, etc. Soldering performance instability and other problems, to achieve the effect of improving the reliability of solder joints, promoting spreading, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Correspondingly, the present invention also provides a method for preparing solid flux as described above, which is characterized in that it includes the following steps:

[0049] Step a, by weight ratio, mixing and stirring the organic co-solvent and the metal active agent;

[0050] Step b, adding an acid active agent to the solution prepared in step a, and standing for 24 hours;

[0051] Step c, heating the solution prepared in step b to 140-145°C to remove moisture brought in or generated during the reaction, and then cooling to room temperature to obtain solid crystals;

[0052] Step d, placing the solid crystalline substance obtained in step c in a reactor, heating and maintaining the temperature at 105-120°C, and stirring until it melts into a liquid substance;

[0053] Step e, adding the corrosion inhibitor to the molten liquid substance, and continuously stirring for 5-30min;

[0054] Step f, cooling the liquid substance in step e to a temperature of 90-95°C, ...

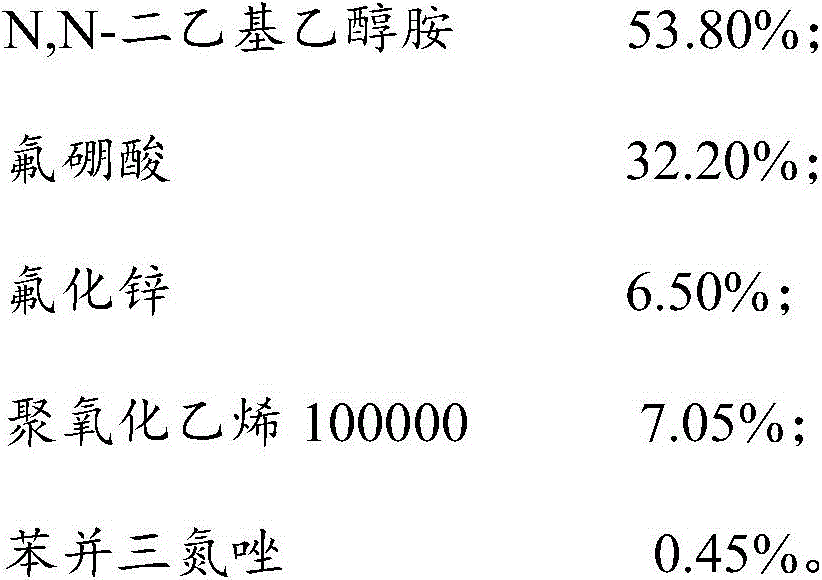

Embodiment 1

[0058] A kind of solid-state flux used for stainless steel soldering, the raw material formula components are as follows:

[0059]

[0060] Configuration method: Weigh N, N-diethylethanolamine and zinc fluoride according to the above ratio and stir evenly in the corrosion-resistant reaction kettle, slowly add the weighed 40%wt concentration of fluoboric acid into the reaction kettle drop by drop place in the reactor for 24 hours until the reaction is complete; heat the above reaction solution to 145°C to fully remove the water, and wait to cool to obtain a solid active mixture; then heat the above solid mixture to 110°C in the reactor, and then add benzotriazepam Add azoles into the above liquid, continue to stir for 20 minutes, add the above ratio of polyethylene oxide 100,000 carrier when the temperature of the liquid flux drops to 90°C, continue to stir until the mixture is uniform, and cool to room temperature to obtain a flux for stainless steel. Solid flux for brazing...

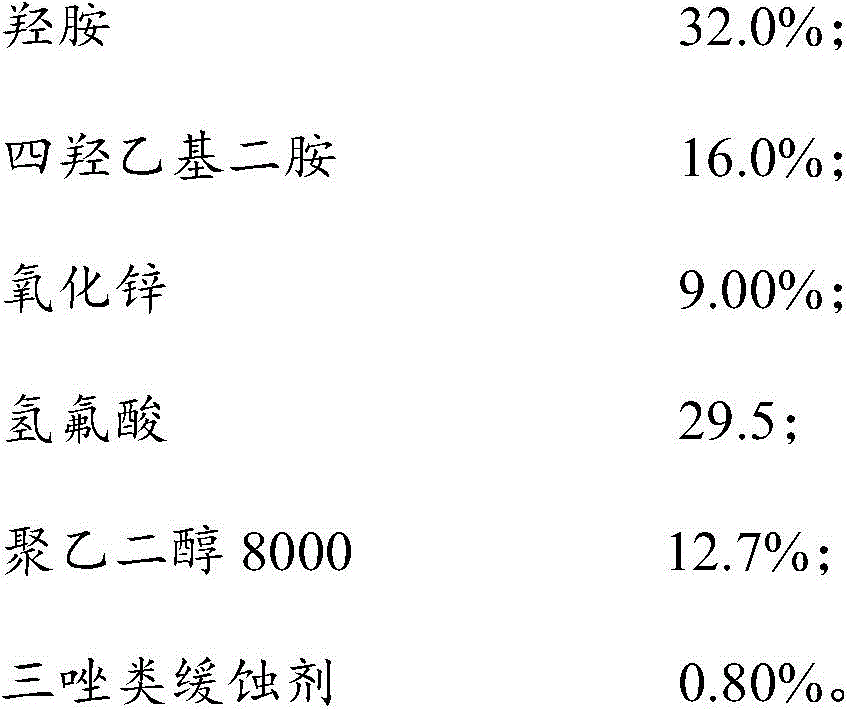

Embodiment 2

[0062] A kind of solid-state flux used for stainless steel soldering, the raw material formula components are as follows:

[0063]

[0064] Configuration method: weigh hydroxylamine, tetrahydroxyethyldiamine, and zinc oxide according to the above ratio and stir evenly in the corrosion-resistant reaction kettle, and slowly add the weighed 40% hydrofluoric acid into the reaction kettle drop by drop , place it for 24 hours until the reaction is complete; heat the above reaction solution to 140°C to fully remove the water, and wait to cool to obtain a solid active mixture; then heat the above solid mixture to 105°C in the reactor, and then add triazole corrosion inhibitors Add the flux into the above-mentioned liquid, continue to stir for 15 minutes, add the polyethylene glycol 8000 carrier of the above ratio when the temperature of the liquid flux drops to 90°C, continue to stir until the mixture is uniform, and cool to room temperature to obtain a Solid flux for stainless ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com