Hot water non-stick surface structure and preparation method thereof

A technology of interface structure and hot water, which is applied in the field of material science, can solve the problems of micro-nano composite structure collapse and inability to completely resist the impact of reverse hot water, and achieve easy operation and regulation, good industrial application prospects, and good reproducibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In a preferred embodiment, the preparation method of the aforementioned superhydrophobic interface structure that does not stick to hot water may include:

[0034] (1) After cleaning the surface of the substrate, dry it with a gas that does not react with the substrate material;

[0035] (2) Place the substrate treated in step (1) in the reaction solution, heat the reaction solution to 25-100°C, and keep it warm for more than 5 minutes, so as to grow and form the nano-array structure on the bottom end surface of the substrate , the reaction solution is a homogeneous solution containing a soluble zinc source substance and a soluble alkaline substance in a molar ratio of 1:6 to 1:10;

[0036] (3) The surface of the nanoarray structure obtained in step (2) is modified with low surface energy substances to form the superhydrophobic interface structure that does not stick to hot water.

[0037] And in a more specific embodiment, this preparation method can comprise:

[003...

Embodiment 1

[0046] 1. Commercially produced 2 mm thick, about 4 cm in area 2 The glass 11 was ultrasonically cleaned with acetone, ethanol, and deionized water for 15 minutes in sequence.

[0047] Blow dry with pure nitrogen to avoid oxidation, and store for later use.

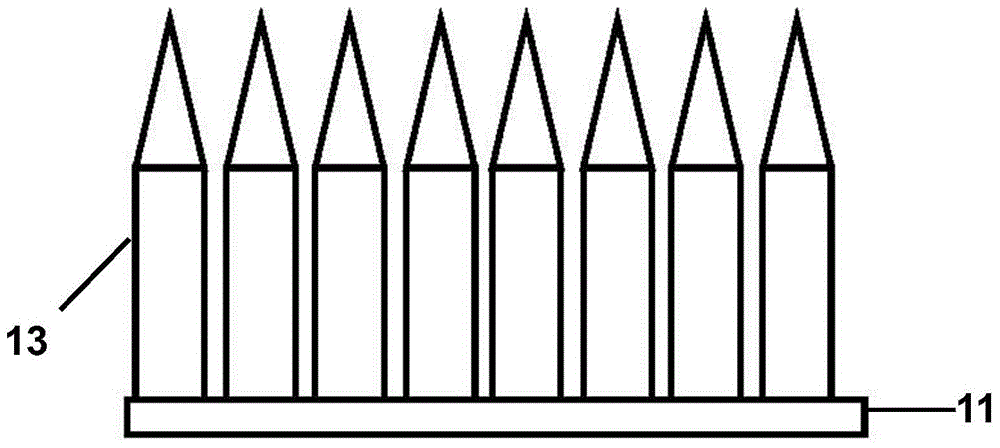

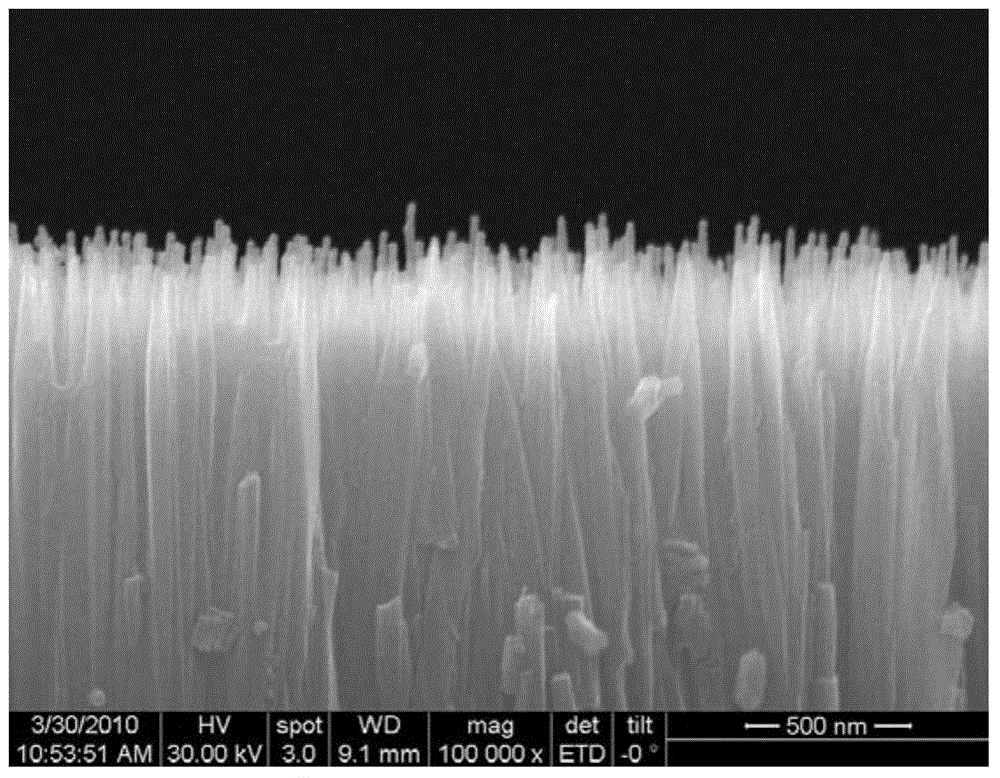

[0048] According to the volume ratio of 1:1, pour the 0.5M zinc nitrate aqueous solution into the 4M sodium hydroxide aqueous solution while stirring to avoid the formation of precipitates. Put the pretreated glass coated with the seed crystal into the reaction liquid with the reverse side up, heat to 90° C. and keep the temperature for 3 hours to obtain the zinc oxide nano-pencil array 13 .

[0049] Surface modification, this step can be achieved by vapor deposition or other modification methods such as first soaking and then drying. Specifically, put the sample to be modified into the o C, after evaporation for 2 hours, take it out after cooling down to room temperature. Or soak in 2% FAS ethanol solution for 2h, t...

Embodiment 2

[0052] 1. A commercially produced copper material 11 with a thickness of 8 mm and an area of about 4 cm2 was selected, and was ultrasonically cleaned with acetone, ethanol, and deionized water for 15 minutes in sequence.

[0053] Blow dry with pure nitrogen to avoid oxidation, and store for later use.

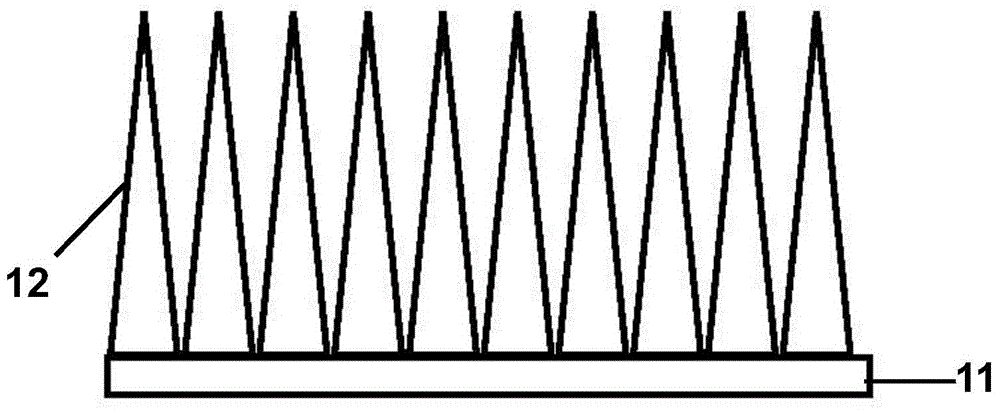

[0054] According to the volume ratio of 1:1, pour the 0.5M zinc nitrate aqueous solution into the 4M sodium hydroxide aqueous solution while stirring to avoid the formation of precipitates. Put the pretreated copper plate into the reaction solution with the reverse side up, heat to 60°C and keep the temperature for 30 minutes to obtain the zinc oxide nanocone structure 12 .

[0055] Surface modification, this step can be achieved by vapor deposition or other modification methods such as first soaking and then drying. Specifically, put the sample to be modified into the o C, after evaporation for 2 hours, take it out after cooling down to room temperature. Or soak in 2% FA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com