Water-based additive having antirust extreme-pressure capability, preparation method and application thereof

An additive, water-based technology, applied in the preparation of water-based additives, water-based additives, water-based additives as lubricant additives in the application field, to achieve the effects of low cost, sufficient raw material sources, convenient and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

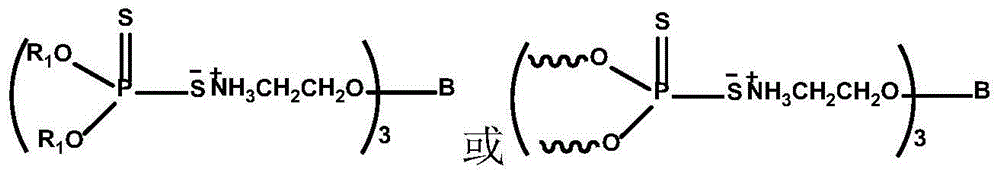

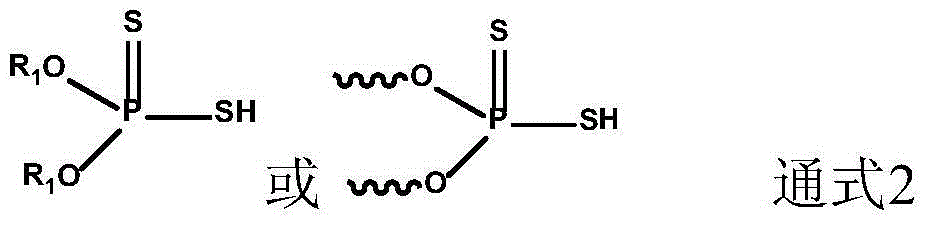

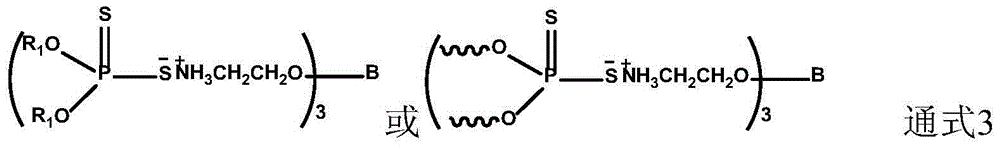

[0023] The borate of the monoethanolamine salt of ethyl phosphorothioate, its synthetic steps are:

[0024] a. Put 0.2mol boric acid, 0.64mol monoethanolamine and a small amount of toluene into a three-necked flask equipped with a stirrer, a thermometer and a water separator as water-carrying agents, stir and react at 100-120°C for 4-8 hours, and wait for the water separator After the water in the solution no longer increases, the reaction ends, and after the remaining toluene, a small amount of water and excess monoethanolamine are removed by distillation under reduced pressure, a light yellow viscous liquid is obtained, which is monoethanolamine borate;

[0025] b. Add 1.3mol ethanol to the three-necked flask, and connect the gas absorption device (aqueous solution of NaOH), use n-heptane as solvent, add 0.4mol P in batches under vigorous stirring 2 S 5 , continue to stir at room temperature for 0.5 ~ 1h, the reaction proceeds violently, exothermic and accompanied by a larg...

Embodiment 2

[0028] The borate of the monoethanolamine salt of polyethylene glycol thiophosphate, its synthetic steps are:

[0029] a. Put 0.2mol boric acid, 0.8mol monoethanolamine and a small amount of toluene into a three-necked flask equipped with a stirrer, a thermometer and a water separator as a water-carrying agent, stir and react at 100-120°C for 4-8 hours, and put it in the water separator After the water no longer increases, the reaction ends, and after the remaining toluene, a small amount of water and excess monoethanolamine are removed by distillation under reduced pressure, a light yellow viscous liquid is obtained, which is monoethanolamine borate;

[0030] b. Add 1.2 mol polyethylene glycol (PEG 200) into a three-necked flask, connect it to a gas absorption device (aqueous solution of NaOH), use n-heptane as a solvent, and add 0.3 mol P in batches under vigorous stirring. 2 S 5 , continue to stir at room temperature for 0.5 ~ 1h, the reaction proceeds violently, exothermi...

Embodiment 3

[0033] The boric acid ester of monoethanolamine salt of lauryl polyoxyethylene ether thiophosphate, its synthetic steps are:

[0034] a. Put 0.2mol boric acid, 0.8mol monoethanolamine and a small amount of toluene into a three-necked flask equipped with a stirrer, a thermometer and a water separator as a water-carrying agent, stir and react at 100-120°C for 4-8 hours, and put it in the water separator After the water no longer increases, the reaction ends, and after the remaining toluene, a small amount of water and excess monoethanolamine are removed by distillation under reduced pressure, a light yellow viscous liquid is obtained, which is monoethanolamine borate;

[0035] b Add 1.2mol lauryl polyoxyethylene ether into the three-necked flask, and connect the gas absorption device (aqueous solution of NaOH), use n-heptane as solvent, add 0.3mol P in batches under vigorous stirring 2 S 5 , continue to stir at room temperature for 0.5 ~ 1h, the reaction proceeds violently, exo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com