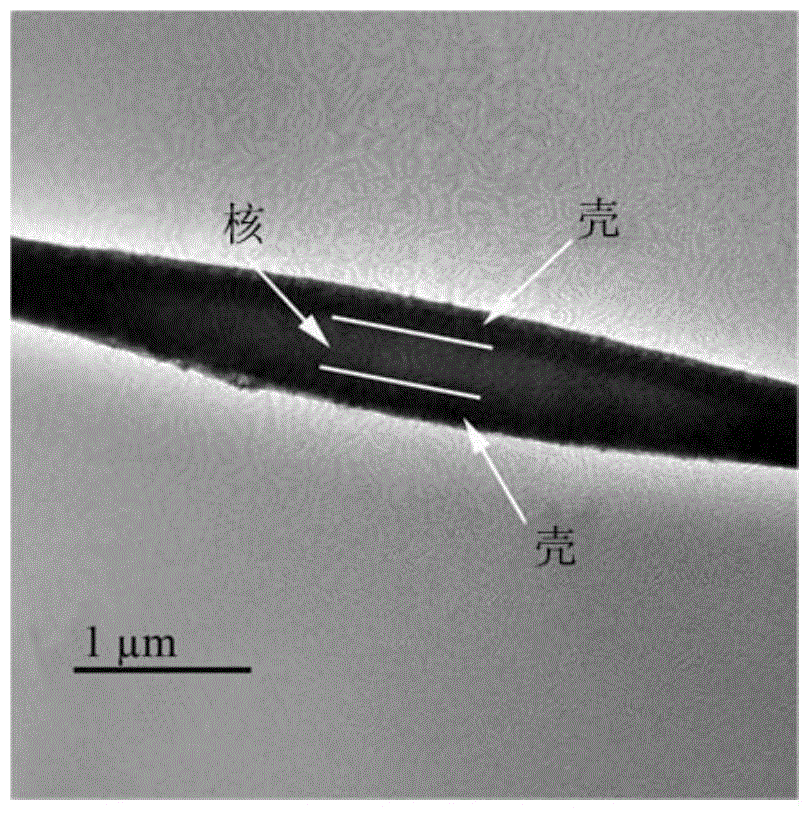

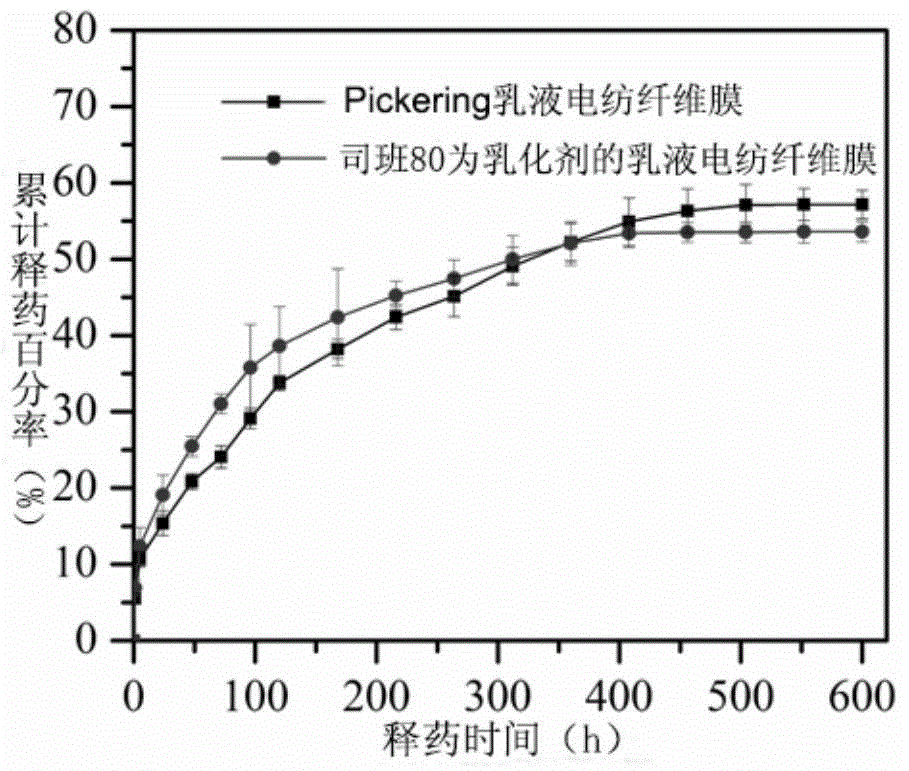

Method for preparing medicine-carrying nanofibers of core-shell structure by virtue of Pickering emulsion electrospinning

A technology of electrospinning and drug-loaded nanometers, which can be used in fiber processing, pharmaceutical formulations, rayon manufacturing, etc., and can solve problems such as limiting nanofiber materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

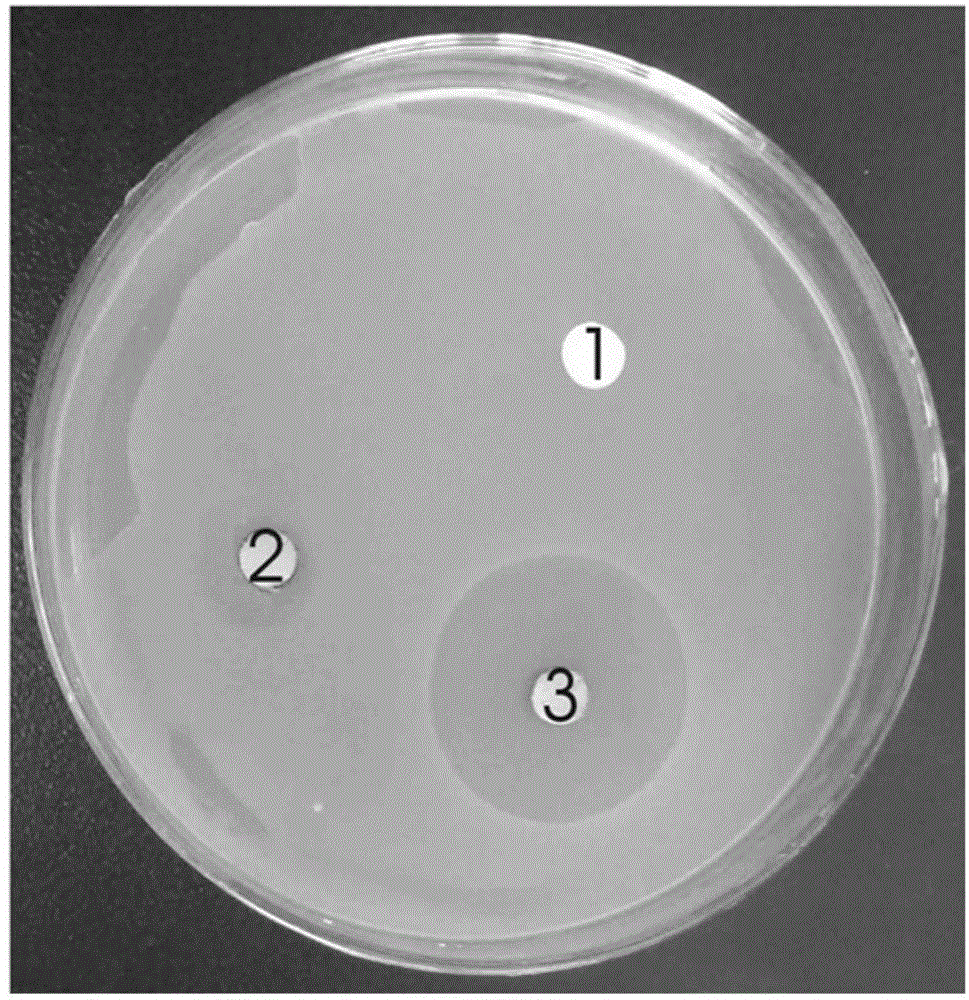

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of amphiphilic modified iron ferric oxide nanoparticle emulsifier: disperse 100mg ferric iron tetroxide ultrasonically for 30min into deionized water to obtain a dispersion with a mass fraction of 10%. Inject 5ml of oleic acid at a speed of 5ml / h to obtain an amphiphilic oleic acid-modified nanoparticle emulsifier;

[0024] (2) Preparation of Pickering emulsion: Firstly, the amphiphilic modified iron ferric oxide nanoparticles prepared in step (1) were dispersed into 1 g N,N-dimethylformamide and 9 g chloroform by ultrasonication for 30 min as an emulsifier Then add 1.0g polylactic acid to the mixed organic solvent of 1g N,N-dimethylformamide and 9g chloroform, fully dissolve under magnetic stirring conditions, and then use this solution as an oil phase at room temperature at high speed Add it under the condition of stirring in the above-mentioned modified iron ferric oxide nanoparticle dispersion with amphiphilicity, and finally add 1.5ml of an aqueous ...

Embodiment 2

[0029] (1) Preparation of amphiphilic modified nano-silica particle emulsifier: 150 mg of nano-silica particle was dispersed in deionized water by ultrasonic 60 min to obtain a dispersion with a mass fraction of 15%. Inject 10ml of oleic acid at a speed of 10ml / h to prepare an amphiphilic oleic acid-modified nano-silica particle emulsifier;

[0030] (2) Preparation of Pickering emulsion: first, the amphiphilic modified nano-silica particles prepared in step (1) were dispersed into a mixed solvent of 10 g tetrahydrofuran and 10 g chloroform as an emulsifier ultrasonically for 60 min, and then 1.5 g Add polyε-caprolactone into the mixed organic solvent of 10g tetrahydrofuran and 10g chloroform and fully dissolve under the condition of magnetic stirring, and then add this solution as an oil phase to the above-mentioned amphiphilic modification under the condition of high-speed stirring at room temperature. In the nano-silica particle dispersion, finally add 2.0ml of an aqueous so...

Embodiment 3

[0035] (1) Preparation of amphiphilic modified iron ferric oxide nanoparticle emulsifier: 200 mg nano iron ferric oxide ultrasonic 60min is dispersed in deionized water to obtain a dispersion with a mass fraction of 20%. Under stirring conditions, Inject 15ml oleic acid at a speed of 15ml / h to prepare oleic acid modified nanoparticle emulsifier;

[0036] (2) Preparation of Pickering emulsion: firstly, the amphiphilic modified iron ferric oxide nanoparticles prepared in step (1) were dispersed into 18 g of N,N-dimethylformamide and 2 g of acetone by ultrasonication for 60 min as an emulsifier Then add 2.0g polylactic acid to the mixed organic solvent of 18g N,N-dimethylformamide and 2g acetone, fully dissolve under the condition of magnetic stirring, then use this solution as oil phase at room temperature Add it into the above-mentioned amphiphilic modified iron ferric oxide nanoparticle dispersion under stirring conditions, and finally add 2.5ml of an aqueous solution containi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com