Experimental method for simulating fault slip

An experimental method and sliding technology, applied in the field of mines, can solve the problems of high manpower and material resources, non-reusable models, large errors, etc., and achieve a highly practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

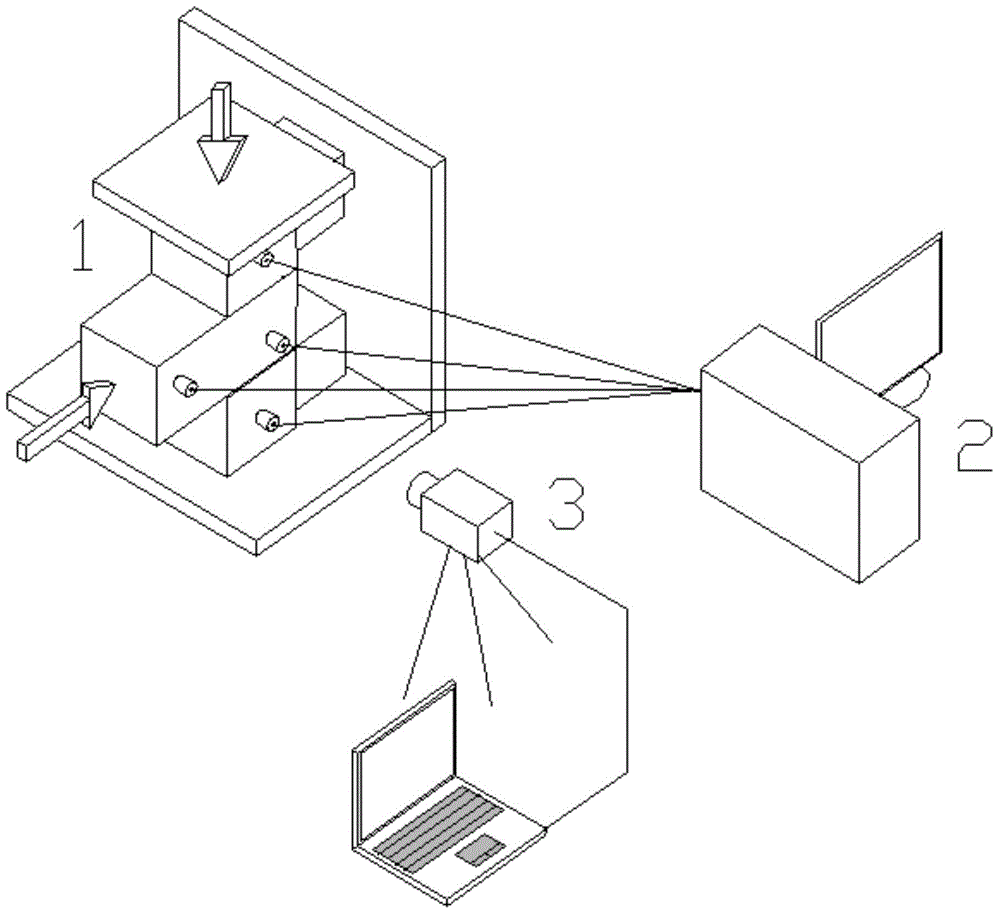

[0018] Such as figure 1 As shown, an experimental system for simulating fault slip is composed of a micro-controlled rock servo pressure testing machine, an acoustic emission monitoring system, a digital camera and a laptop computer; the digital camera is connected to the laptop computer, and the micro-controlled rock servo pressure test The machine is composed of a main engine, a pressure chamber and a microcomputer control system. The main engine is a four-column loading frame, and the oil cylinder is placed below; the pressure chamber is made of high-quality alloy steel forgings, and the surface is plated with hard chrome; High performance, complete protection functions and strong reliability. Therefore, the system can satisfy independent loading in vertical direction and horizontal direction, and the loading stress and stress loading speed can be precisely controlled b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com