Chamber assembly for synthesizing diamond and cubic boron nitride sintered body and assembling method

A technology of cubic boron nitride and synthetic diamond, which is applied in the fields of diamond for cutting tools, drilling, and cubic boron nitride manufacturing. Problems such as the overall performance of the layer and the performance of superhard material tools are affected, and the effects of high synthesis integrity, small deformation, and low porosity are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

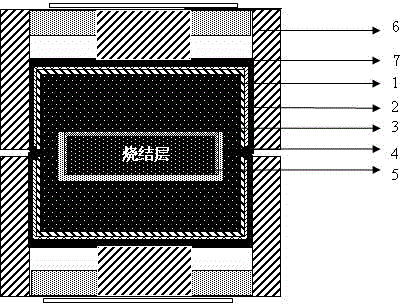

[0015] The invention mainly relates to cavity assembly and cavity assembly method for synthesizing diamond and cubic boron nitride sintered bodies. The present invention adopts the assembly of the cavity to prepare a large-sized sintered body of superhard material (Φ 40 mm*5 mm or more), can effectively control the stability of the synthetic cavity and the uniformity of the pressure field and temperature field, and make the structure of the sintered body The structure is dense and uniform, and at the same time, it can suppress the sintering deformation of diamond and cubic boron nitride, thereby further improving the quality and integrity of the sintered body.

[0016] The cavity assembly is composed of pyrophyllite composite block 6, graphite heating tube 7, magnesium oxide cup, iron cup, graphite cup, molybdenum cup, and niobium cup. The magnesium oxide cup and iron cup assembled in the graphite heating tube in the pyrophyllite composite block , graphite cups, molybd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com