Method for preparing rapid solidified fine spherical high-silicon high-wear-resistant aluminum-silicon alloy powder

An aluminum-silicon alloy, high wear-resistant technology is applied in the field of preparation of rapidly solidified fine spherical high-silicon and high-wear-resistant aluminum-silicon alloy powder, which can solve the limitation of the application range of aluminum-silicon alloy, the increase of oxygen content and water content, and the range of alloy crystallization. increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Metal aluminum ingot with a purity of 99.85%, weighed 55Kg, first added to a non-polluting crucible and heated to 850°C, then a metal silicon block with a purity of 99.7%, weighed 45Kg, added to molten aluminum to heat up After reaching 950°C, fully stir, then place the entire crucible furnace directly above the atomization device, and use 4MP pressure and 300°C nitrogen to spray at a cooling rate of 10 3 ~10 4 In the K / s atomization chamber, the aluminum-silicon alloy powder with an average size of 50 μm is collected.

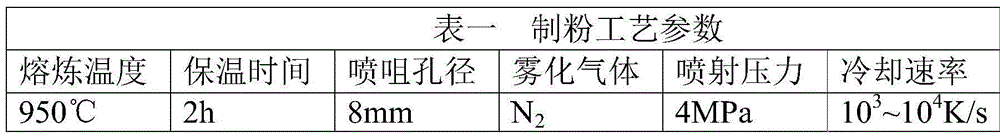

[0015] Its preparation process parameters are attached in Table 1:

[0016]

[0017] Properties of aluminum silicon alloy powder:

[0018] Tap density: 1.221g / cm 3 , bulk density: 0.667g / cm 3 , Oxygen content: 0.41%, water content: 0.1%.

[0019] Chemical composition: Fe≤0.6%, Si44%, Cu3.5%, Al52.3%, other 0.4%.

Embodiment 2

[0020] Example 2: Metal aluminum ingots with a purity of 99.85%, weighed 55Kg, were first added to a non-polluting crucible, heated to 850°C, and then metal silicon blocks with a purity of 99.7%, weighed 45Kg, were added to molten aluminum , stir after heating up to 950°C, then place the entire crucible furnace directly above the atomization device, use 5MPa pressure, nitrogen spray at 300°C temperature at a cooling rate of 10 3 ~10 4 In the atomization chamber of K / s, the aluminum-silicon alloy powder with an average particle size of 42 μm is collected.

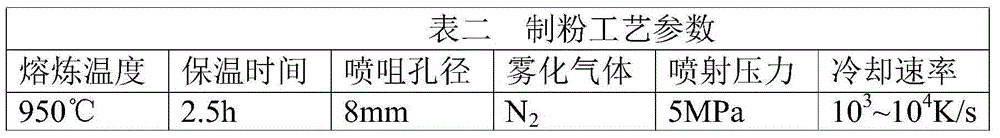

[0021] Its preparation process parameters are attached in Table 2:

[0022]

[0023] Properties of aluminum silicon alloy powder:

[0024] Tap density: 1.33g / cm 3 , bulk density: 0.72g / cm 3 , Oxygen content: 0.41%, water content: 0.1%.

[0025] Chemical composition: Fe≤0.6%, Si44%, Cu3.5%, Al52.3%, other 0.4%.

Embodiment 3

[0026] Example 3: Metal aluminum ingots with a purity of 99.85%, weighed 55Kg, were first added to a non-polluting crucible, heated to 850°C, and then metal silicon blocks with a purity of 99.7%, weighed 45Kg, were added to molten aluminum , stir after heating up to 950°C, then place the entire crucible furnace directly above the atomization device, use 8MPa pressure, 300°C nitrogen spray at a cooling rate of 10 3 ~10 4 In the K / s atomization chamber, the aluminum-silicon alloy powder with an average particle size of 28 μm is collected.

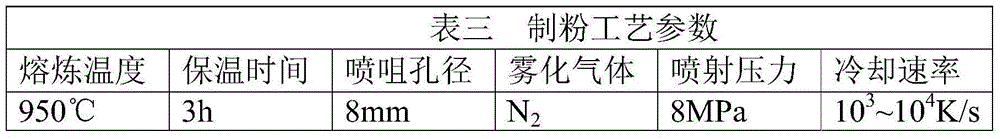

[0027] Its preparation process parameters are listed in Table 3:

[0028]

[0029] Properties of aluminum silicon alloy powder:

[0030] Tap density: 1.32g / cm 3 , bulk density: 0.79g / cm 3 , Oxygen content: 0.41%, water content: 0.1%.

[0031] Chemical composition: Fe≤0.6%, Si44%, Cu3.5%, Al52.3%, other 0.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com