Vertical multistage AO ecological sewage treatment system

A sewage treatment system, vertical technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high construction cost, limited sewage treatment capacity, etc. The effect of short construction period, reduction of external carbon sources, and reduction of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

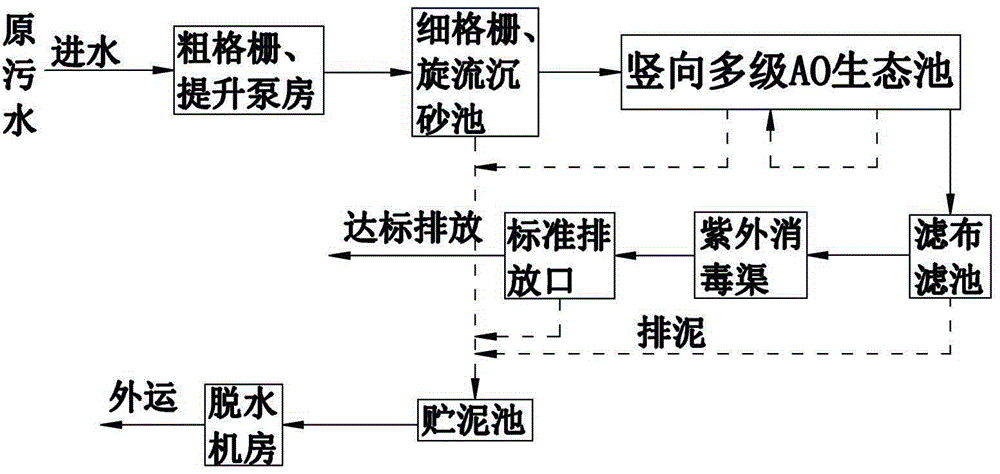

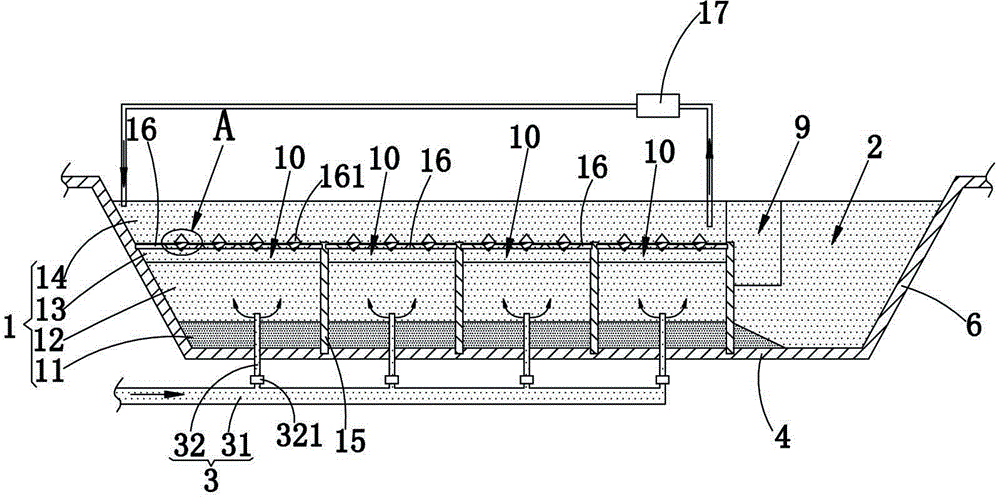

[0031] refer to figure 1, a vertical multi-stage AO ecological sewage treatment system, the sewage is treated sequentially through coarse screens, lifting pump rooms, fine screens, grit chambers, vertical multi-stage AO ecological pools, filter cloth filters, and ultraviolet disinfection channels Standard outlet discharge. The sludge generated by the fine grid, grit chamber, vertical multi-stage AO ecological pool and standard discharge port is transferred to the sludge storage tank, and can be transported outside after being treated in the dehydration machine room. Furthermore, both the coarse grill and the fine grill adopt a rotary grill decontamination machine, a submersible sewage pump is installed in the lifting pump room, and the grit chamber adopts a swirl grit chamber. The ecological sewage treatment system is also equipped with a biological deodorization system divided into two parts, one is the collection system, and the other is the treatment system. The collectio...

Embodiment approach 2

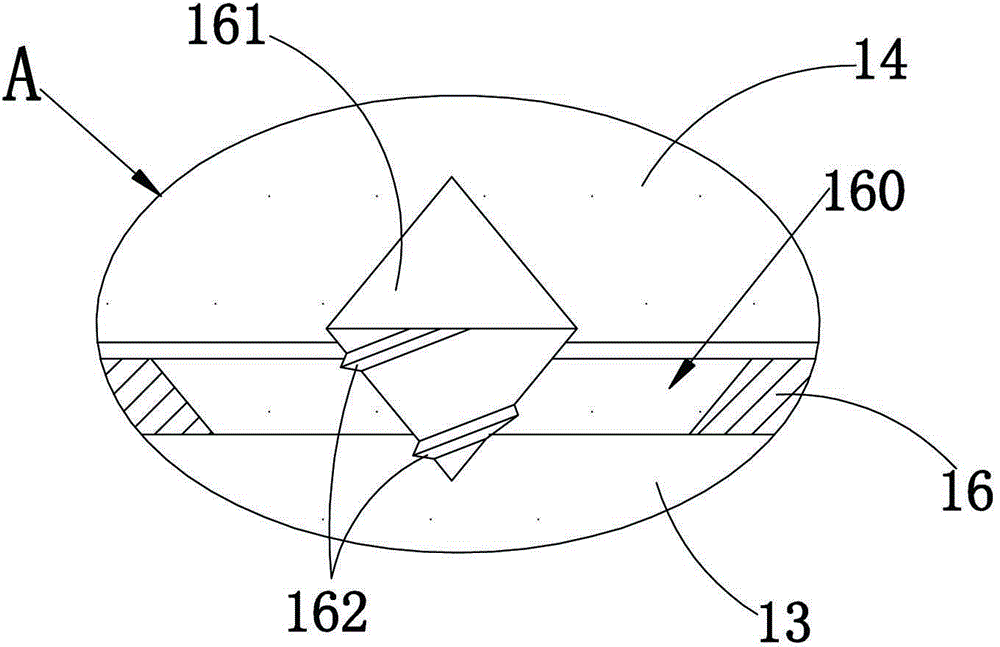

[0043] The difference between this embodiment and Embodiment 1 is that: refer to Figure 6 , Figure 7 , the guide body 161 of the present embodiment is a hollow structure, and the upper cone wall of the guide body 161 is provided with some air outlet holes 167, and the lower cone wall of the guide body 161 is provided with several water holes 163, or as Figure 4 , Figure 5 As shown, the water hole 163 is arranged at the bottom of the guide body 161, and the inside of the guide body 161 is equipped with an aerobic filler 164 and / or anoxic filler 164, and the guide body 161 is also equipped with a gas supply pipe for connecting to it. The aeration pipe 165 constitutes an aeration structure. The air blown into the aeration pipe 165 is discharged upwards from the air outlet 167, and the sewage flowing upwards from the anoxic layer 13 can also enter the guide body 161 through the water hole 163, and the sludge entering the guide body 161 can also pass through the water guide b...

Embodiment approach 3

[0045] The difference between this embodiment and Embodiment 1 is that: refer to Figure 8 , Figure 9 , the aeration structure of the present embodiment adopts the conventional aeration device 18 of the prior art, referring to Figure 10 , the aeration device 18 is disposed above each through hole 160 , and the aeration device 18 is assembled on the above-mentioned ballast plate 16 . The aeration device 18 includes a main box body 181 with an open top, and a plurality of through flow holes 180 are arranged at the bottom of the main box body 181 . The top edges of the two opposite outer walls of the main box body 181 are respectively fixed with floating strips 183 with a density lower than that of sewage. The setting of the floating strips 183 reduces the dependence of the main box body 181 on the supporting frame. Such as Figure 10 As shown, the side wall of the main box 181 is provided with two air intake ducts 182, the inner end of the air intake duct 182 communicates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com