An electro-osmotic sludge dewatering machine

A technology of sludge dewatering machine and electroosmosis, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc. It can solve the problems of surrounding environmental pollution, affecting the operation and management of garbage disposal sites, perishable and odorous, etc., and achieves high safety factor, Good dehydration efficiency and odor reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

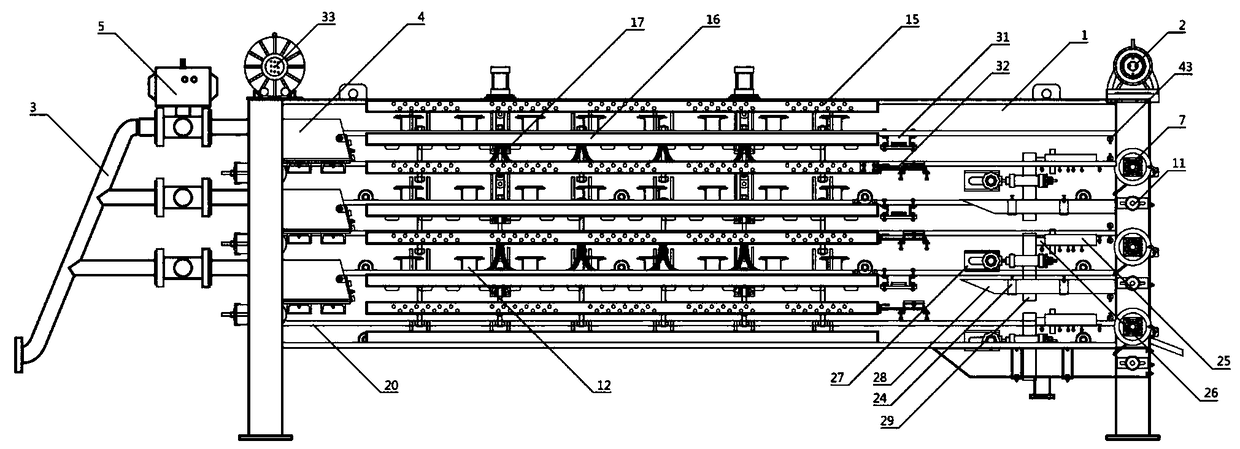

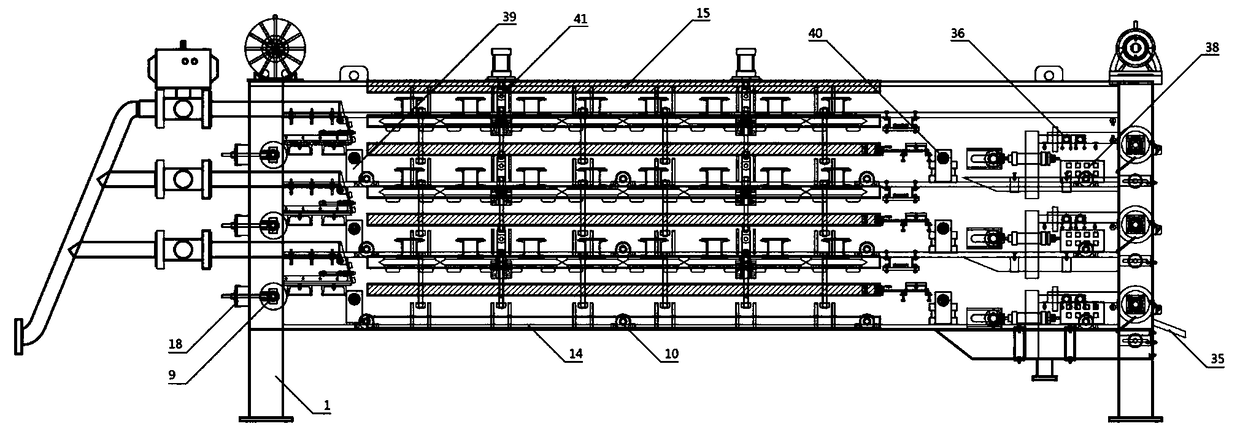

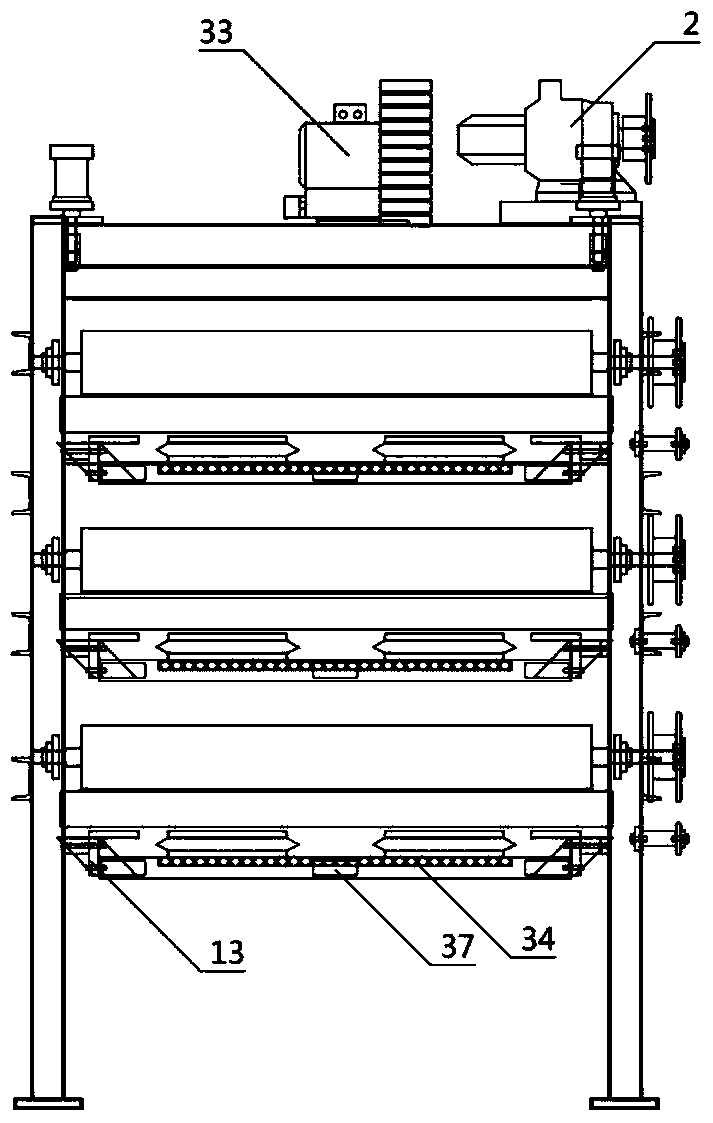

[0043] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0044] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 An electro-osmotic sludge dewatering machine is shown, which is characterized in that it includes a main frame 1, a turbo air pump 2, an intake and exhaust pipeline 3, a mud inlet pipeline 5, several power rollers 7, a reduction motor 33 and a mud outlet guide plate 35 , the turbo air pump 2 is located on the top of the main frame 1, the turbo air pump 2 is fixedly connected to the main frame 1, the intake and exhaust duct 3 is located on one side of the main frame 1, the intake and exhaust duct 3 is connected to the main frame The frame 1 is fixedly connected, the mud inlet pipeline 5 is located on the upper part of the air intake and exhaust pipeline 3, the mud inlet pipeline 5 is fixedly connected with the air inlet and exhaust ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dryness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com