High-temperature-resistant and anticorrosive composite ceramic coating

A technology of anti-corrosion coatings and composite ceramics, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of inability to meet long-term anti-corrosion requirements and short validity period, and achieve the effects of strong anti-aging performance, long service life and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

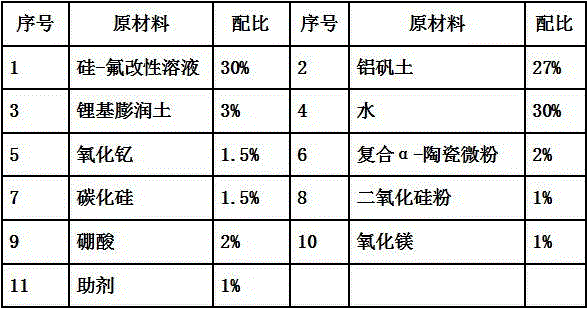

[0011] Firstly (1) make the pre-made lithium bentonite into a gel, then add a certain amount of water and additives, add refractory aggregate bauxite and additives after ball milling for 20 minutes, continue ball milling for 30 minutes (2) mix the silicon-fluorine solution Stir and ripen at high speed, the speed of the mixer should reach more than 3500 / min, stir for more than 30 minutes, and leave the stirred solution for more than 2 hours to mature; (3) gradually add the mature silicon-fluorine solution to the ground under stirring at 3000 / min Lithium-based bentonite bauxite-based powder, yttrium oxide, composite α-ceramic micropowder, silicon carbide, silicon dioxide powder, magnesium oxide, etc. chelate and stir for 30 minutes. Finally, boric acid is added for stabilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com