Solid alkali and the method of utilizing solid alkali to realize the synergistic deacidification and decolorization of waste oil

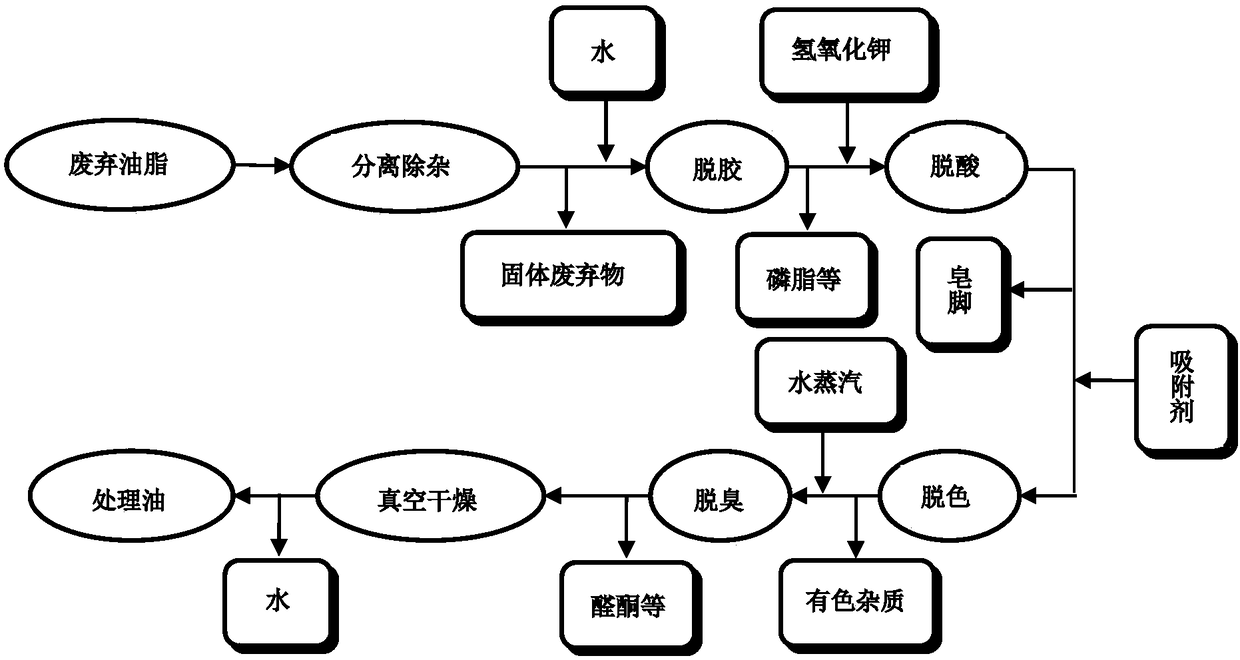

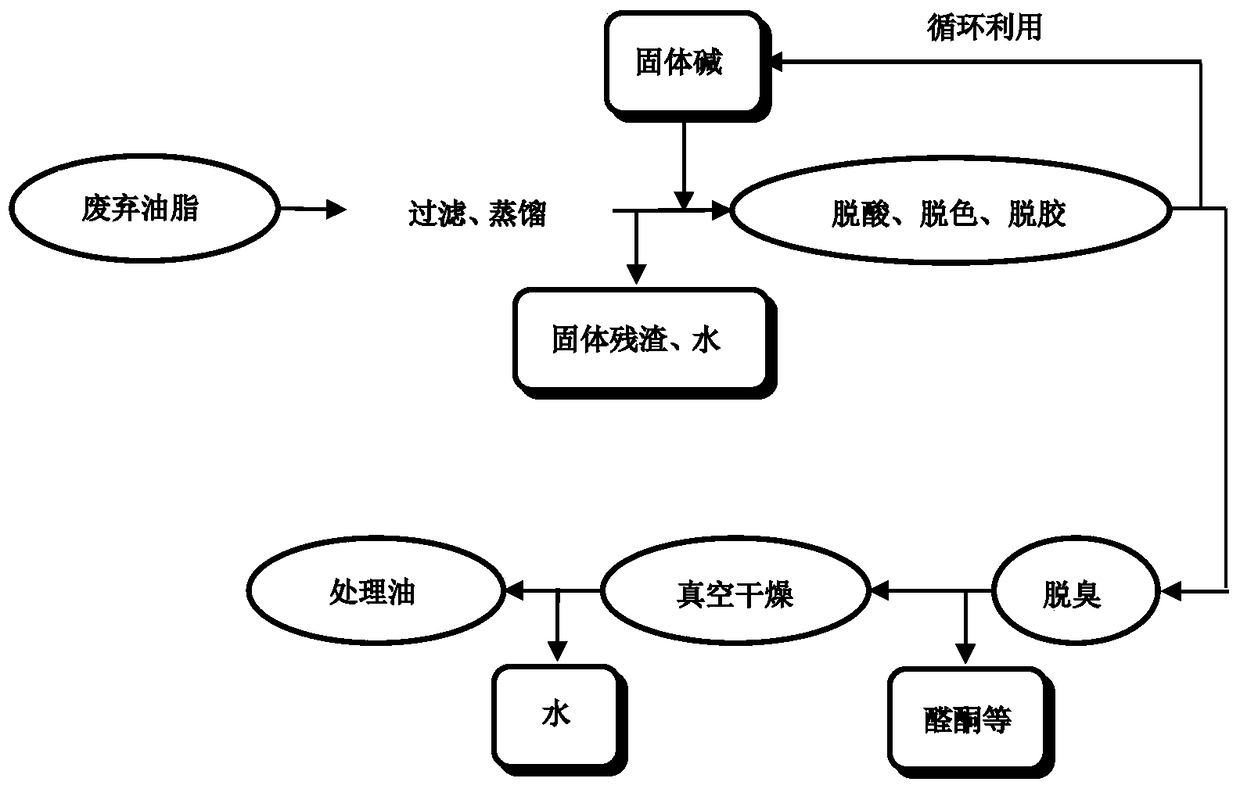

A technology of solid alkali and waste oil, which is applied in chemical instruments and methods, fat oil/fat refining, and other chemical processes. It can solve problems such as complex processes, harsh method conditions, and unsatisfactory conditions, so as to save process flow and neutral oil. High yield and good decolorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The basic preparation parameters of solid base #1 are: take 60 parts by mass of activated carbon and 40 parts of activated clay, fully grind and mix activated carbon and activated clay, add 500 parts of dilute hydrochloric acid, filter after stirring for 1 hour, rinse with distilled water until Neutral, take it out after drying at 105-110°C for 2 hours, add the obtained mixture of activated carbon and activated clay to the prepared impregnation treatment solution with a concentration of 10% NaOH solution, stir at room temperature for 12 hours, filter to obtain solid alkali, and place it in an oven After drying at 105-110°C for 3 hours, take it out, put it in a desiccator to cool, and set it aside.

[0036] Filter and distill waste oil #1 to remove solid residue and moisture, weigh 100kg of waste oil that has been filtered and distilled, add 15kg of solid alkali #1, stir for 30 minutes at a temperature of 70°C, and filter to separate the solid After alkali and treated oi...

Embodiment 2

[0040] Waste oil #2 is filtered and distilled to remove solid residue and moisture, weigh 100 kg of waste oil processed through filtration and distillation, add 15 kg of solid base #1 (prepared as in Example 1), and heat at a temperature of 70° C. , stirred for 30 minutes, filtered to separate the solid alkali and the treated oil, and washed the treated oil with water for 3 times.

[0041] Table 2 is the comparison table of parameters of waste oil before and after treatment in embodiment 2

[0042]

Embodiment 3

[0044] The basic preparation parameters of solid base #2 are: 65 parts by mass of activated carbon and 35 parts of activated clay. After fully grinding and mixing the activated carbon and activated clay, add 500 parts of dilute hydrochloric acid, filter after stirring for 1 hour, and rinse with distilled water to medium Take it out after drying at 105-110°C for 2 hours, add the obtained mixture of activated carbon and activated clay to the prepared impregnating treatment solution with a concentration of 20% NaOH solution, stir at room temperature for 12 hours, filter, and place the solid base at 105-110 After drying at ℃ for 3 hours, take it out, put it in a desiccator to cool, and set it aside.

[0045] Filter and distill waste oil #2 to remove solid residue and water, weigh 100kg of waste oil that has been filtered and distilled, add 10kg of solid alkali #2, stir for 20min at a temperature of 80°C, and filter to separate the solid After alkali and treated oil, the treated oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com