A single sulfur source temperature control process to improve the uniformity of molybdenum disulfide thin film growth

A molybdenum disulfide, thin film growth technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problem that the vulcanization time of molybdenum trioxide cannot be accurately controlled, so as to avoid premature vulcanization and avoid reaction. Uncontrollable, improved uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

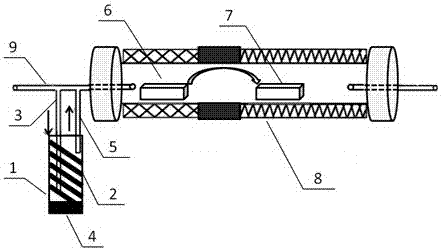

[0017] Example: refer to figure 1 , using molybdenum trioxide 6 as the Mo source and sapphire 7 as the substrate, the growth of molybdenum disulfide thin films was carried out.

[0018] (1) Finely polish the inner surface of the stainless steel bottle 1 with a diameter of 25mm and a height of 150mm to avoid chemical corrosion of the inner surface of the bottle 1 by sulfur at high temperature;

[0019] (2) Put the material bottle 1 outside the tube furnace, the material bottle 1 is provided with argon gas input pipe 3 and argon gas output pipe 5, and connect the argon gas input pipe 3 and argon gas output pipe 5 with the tube furnace 8 The argon gas input pipe 9 communicates;

[0020] (3) Put 5-10g of sulfur powder 4 in the feeding bottle 1;

[0021] (4) Wrap the heating cable 2 tightly around the periphery of the material bottle 1 to realize the heating of the material bottle 1. The maximum heating temperature of the heating cable 2 is 300°C;

[0022] (5) Connect the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com