Detection method, sampling device and sampling equipment of no-cleaning particle concentration

A particle concentration and sampling device technology, which is applied in the field of no-clean particulate concentration detection and no-clean particulate concentration sampling device, can solve the problems of complex cleaning operation, high sampling time and sampling conditions, and inaccurate chemical reagent testing. , to achieve the effect of simple test steps and process, avoiding the difficulty of manual cleaning, and accurate and reliable test structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This embodiment provides a method for detecting the concentration of no-clean particulate matter, which detects the concentration of particulate matter based on a weighing method through a detachable sampling device;

[0063] The sampling device includes a first half shell, a second half shell and a fume filter element; the oil fume filter element is located in a cavity formed by the first half shell and the second half shell; the first half shell, the second half shell The shell can be, but not limited to, stainless steel or polytetrafluoroethylene;

[0064] The oil fume filter element includes a first membrane structure and a second membrane structure;

[0065] The inlet of the sampling device is arranged on the first half-shell, and its outlet is arranged on the second half-shell; along the direction from the inlet to the outlet are the first half-shell, the first half-shell, Membrane structure, the second membrane structure and the second half-shell; preferably, th...

Embodiment 2

[0088] In order to better implement the detection method of the no-clean particle concentration in Embodiment 1 of the present invention, the present invention also provides a sampling device for realizing the no-clean particle concentration of the present invention. The implementation of the sampling device for cleaning the concentration of particulate matter will be further described in detail.

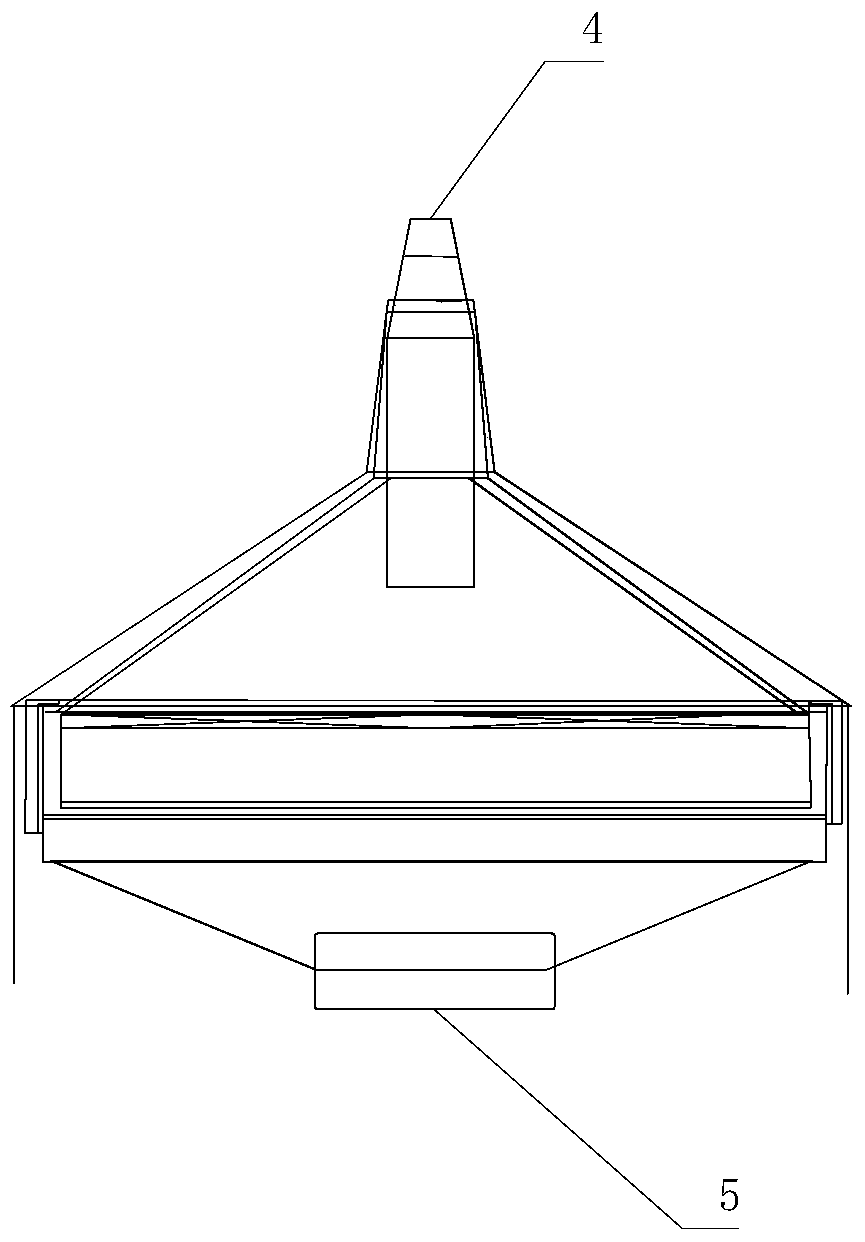

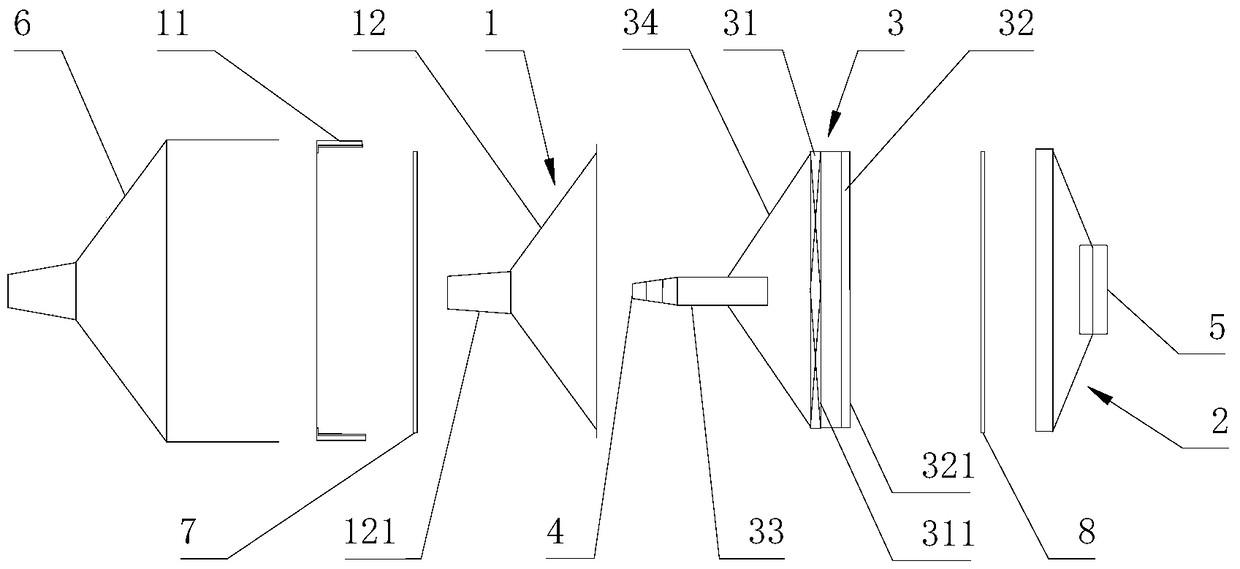

[0089] see figure 1 , figure 2 As shown, the present embodiment provides a sampling device for no-cleaning particle concentration; figure 1 It is a structural schematic diagram of the sampling device; figure 2 is an exploded view of the sampling device; in order to show the structure more clearly, figure 1 Shown is a cutaway view of the sampling device, figure 2 The fume filter shown is shown in cutaway view.

[0090] see figure 1 , figure 2 As shown, the no-clean particulate matter concentration sampling device provided in this embodiment includes a first half shell 1, a...

Embodiment 3

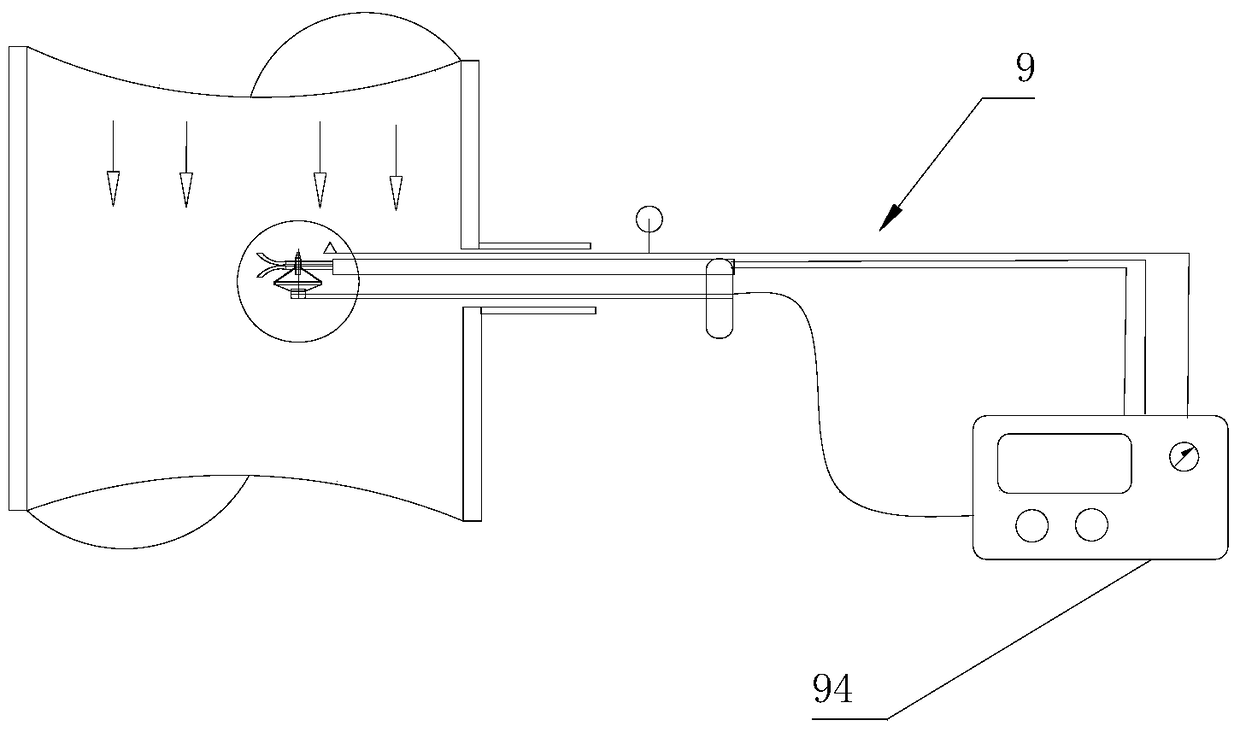

[0115] see image 3 , Figure 4 As shown, this embodiment provides a sampling device for no-cleaning particle concentration, and the sampling device for no-cleaning particle concentration includes the sampling device for no-cleaning particle concentration in Embodiment 2; the technical solution disclosed in Embodiment 2 It also belongs to this embodiment, and this embodiment will not be described again.

[0116] image 3 Schematic diagram of the structure of the sampling device for the no-cleaning particle concentration provided in this embodiment, the figure shows the state where the tip of the sampling gun is inserted into the chamber of the sampling gas, and the direction of the arrow shown in the figure is the flow velocity direction of the sampling gas; Figure 4 for image 3 A close-up view of the sampling device for the indicated no-clean particulate concentration.

[0117] see image 3 , Figure 4 As shown, the sampling device for no-cleaning particle concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com