Optical module

A technology of optical modules and optical paths, applied in the field of optical modules, can solve problems such as signal transmission loss, solve heat dissipation problems, and achieve heat dissipation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

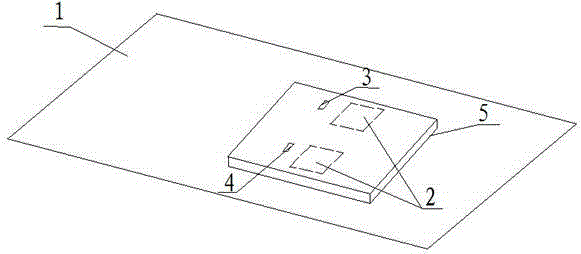

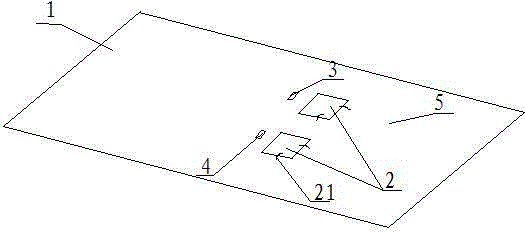

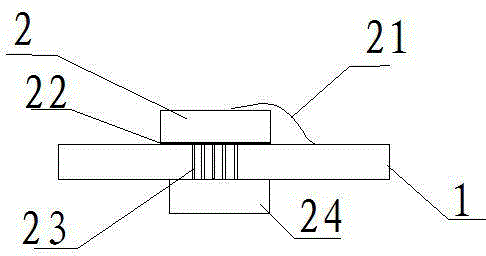

[0018] The embodiment of the present application provides an optical module to solve the heat dissipation problem of the driver chip in the optical module; a heat sink is mounted on the surface of the driver chip buckled by the lens assembly cover, and the heat sink is connected with the heat sink laid on the circuit board. The heat conduction layer is connected, and the heat conduction layer is partly or completely laid outside the space of the lens assembly cover buckle, and conducts the heat emitted by the driver chip out of the lens component cover buckle space, realizing the technical effect of dissipating heat.

[0019] In order to better understand the above technical solution, the above technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation manners.

[0020] Such as Figure 4 with Figure 7 As shown, it is a schematic structural diagram of the optical module proposed in the embodiment of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com