Efficient mould-proof, antibacterial, insect-prevention and deodorization functional microcapsules and application thereof

An anti-mildew, antibacterial, microcapsule technology, applied in application, deodorization, bactericide and other directions, can solve the problem of difficult to achieve safety protection, and achieve the effect of long validity period and efficient anti-mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

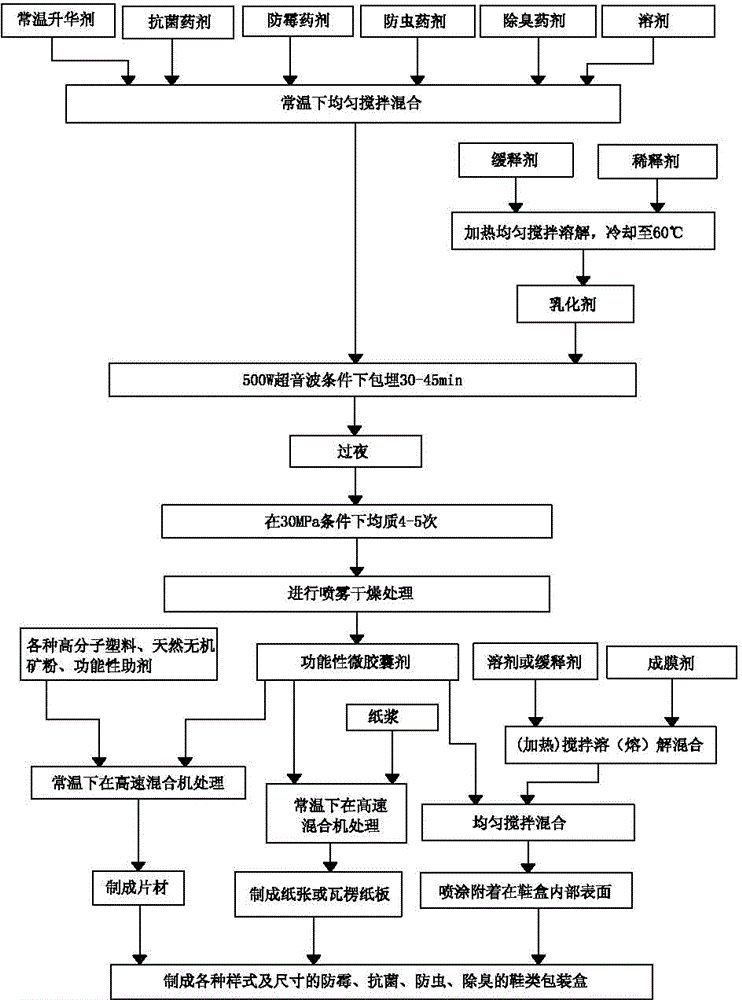

[0039] Stir the normal temperature sublimation agent, antibacterial agent, deodorant agent, insect repellant agent, antifungal agent, and solvent evenly at room temperature into a functional mixture for later use; weigh the slow release agent, add the diluent, heat evenly and stir to dissolve, then cool to Add emulsifier and functional mixture at 60°C, embed under 500W ultrasonic conditions for 30-45 min, overnight, and homogenize 4-5 times under 30MPa conditions, and then spray-dry to obtain functional microcapsules.

[0040] After mixing this functional microcapsule with pulp, it can be made into paper or corrugated cardboard of various grammes; After corona, the sheet is made into a sheet, and then the sheet is made into various styles and sizes of anti-mildew, anti-bacterial, anti-insect, and deodorizing shoe packaging boxes.

[0041]

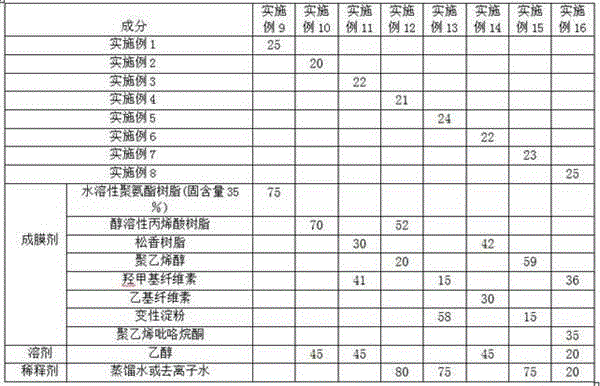

Embodiment 9

[0043] The functional microcapsules prepared in Example 1 are added to the water-soluble polyurethane resin solution, stirred and mixed evenly at room temperature, and then attached to the inner surface of the shoe box by spraying to obtain mildew-proof, anti-bacterial, insect-proof and deodorizing products. shoe packaging box.

Embodiment 10

[0045] Stir the alcohol-soluble acrylic resin and the solvent at room temperature until the solution is completely dissolved, then add the functional microcapsules prepared in Example 2, stir and mix evenly at room temperature, and then adhere to the inner surface of the shoe box by spraying. The mold-proof, antibacterial, insect-proof and deodorizing shoe packaging box can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com