A kind of preparation method of aluminum sol

A technology of aluminum sol and aluminum chloride, which is applied in chemical instruments and methods, aluminum compounds, colloidal chemistry, etc., can solve the problems of expensive raw materials for preparing aluminum sol, and achieve the effects of reducing the production risk factor, simplifying the process, and reducing the preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

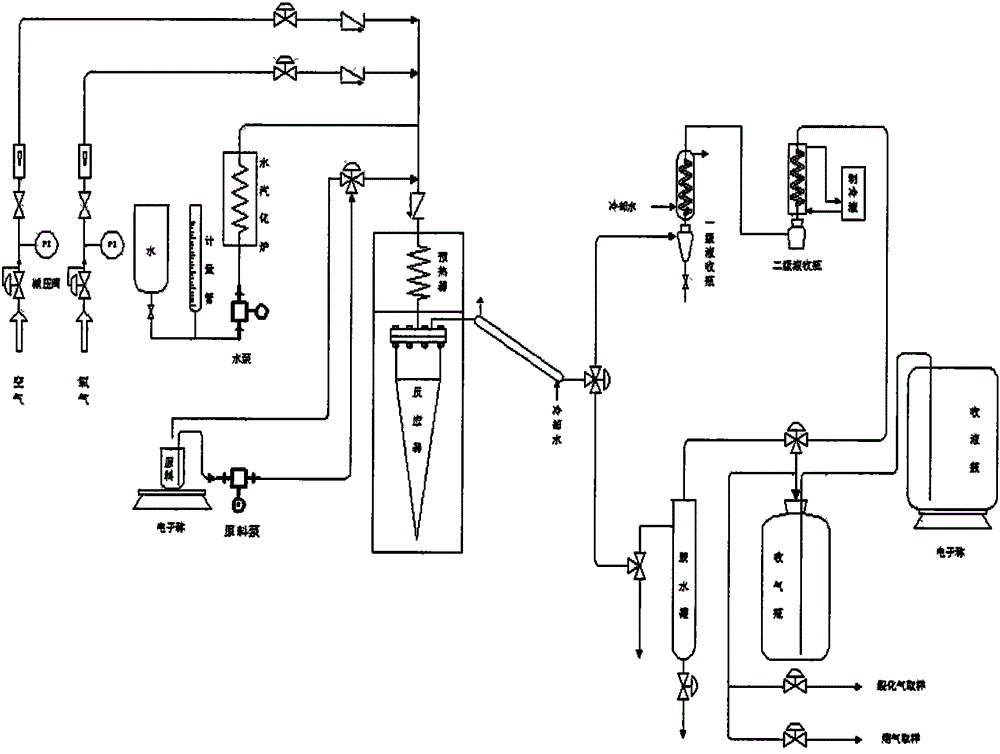

Method used

Image

Examples

Embodiment 1

[0027] (1) Select the spent catalyst CAT-1 unloaded from the FCC unit, then mix and stir it with an acetic acid buffer solution with a pH value of 4, and heat it to 90°C, then add EDTA solution to the mixed system, and keep the temperature at 90°C for reaction 4 hours, wherein the weight ratio of organic acid:complexing agent:water:spent catalyst in the mixed system is 2:1.5:6:1, and then the obtained product is washed and filtered. Wherein, the heavy metal content (ppm) in the filter cake: iron, nickel, vanadium, calcium, sodium are 562,136,152,262,224 respectively.

[0028] (2) Re-beat the filter cake in step (1), mix and stir with hydrochloric acid solution with a pH value of 1, and heat to 90°C, keep the temperature for 4 hours, wherein the hydrochloric acid in the system: water: the weight of the filter cake The ratio is 1.5:6:1, and then the resulting product is filtered.

[0029] (3) Transfer the filtrate in step (2) to the reaction kettle, add aluminum particles, cont...

example 2

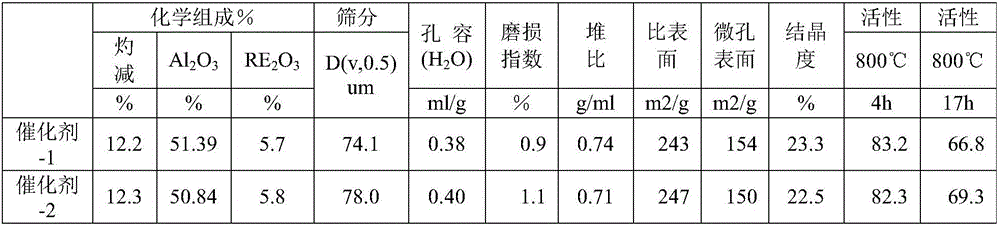

[0033] Take 40 parts by weight of kaolin on a dry basis, 10 parts by weight of aluminum sol-1 on a dry basis, 18 parts by weight of pseudo-boehmite on a dry basis and 32 parts by weight of HCRY on a dry basis (produced by our company) mixed and stirred, the acid-aluminum ratio is 0.07, sprayed in a small spray granulation tower, roasted in a muffle furnace at 450°C for 2 hours, washed, and dried to obtain catalyst microspheres, which are recorded as catalyst-1.

example 3

[0035] Get the kaolin of 40 parts by weight on a dry basis, the aluminum sol A (Hunan Xinpeng) of 10 parts by weight on a dry basis, the pseudo-boehmite of 18 parts by weight on a dry basis and 32 parts by weight on a dry basis HCRY (produced by our company) in parts by weight is mixed and stirred, the acid-aluminum ratio is 0.07, sprayed in a small spray granulation tower, roasted in a muffle furnace at 450°C for 2 hours, washed, and dried to obtain catalyst microspheres, which are recorded as catalysts -2.

[0036] The analysis result of catalyst in the example is as follows

[0037]

[0038] Catalyst Aging: The two prepared catalysts were hydrothermally treated at 800°C and 100% steam for 17 hours before use.

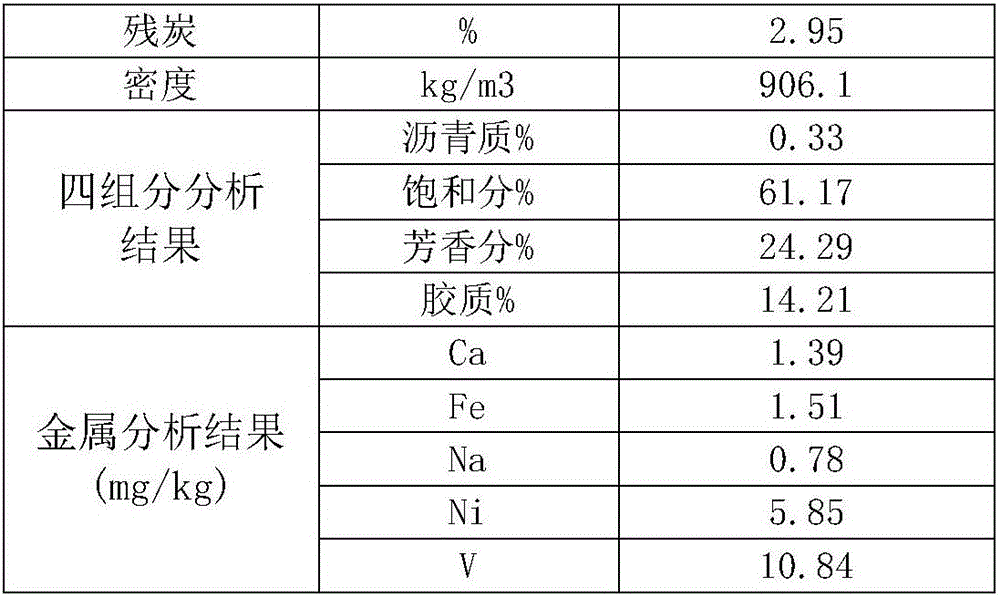

[0039] Catalyst evaluation: The evaluation of catalyst was carried out on FFB fixed fluidized bed. The raw material is Changyi No. 1 catalytic raw material oil (see attached table 1 for the properties of the raw material), the reaction temperature is 500°C, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com