Preparation method for metal capturing agent

A technology of metal trapping agent and waste catalyst, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, catalyst protection, etc., can solve the problems of waste of resources, high safety landfill cost, etc., and achieve Reduce production cost, reduce dry gas and coke yield, and improve the effect of metal capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

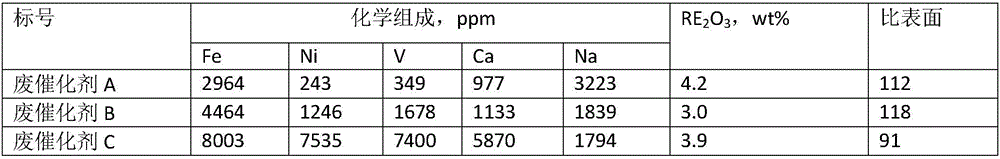

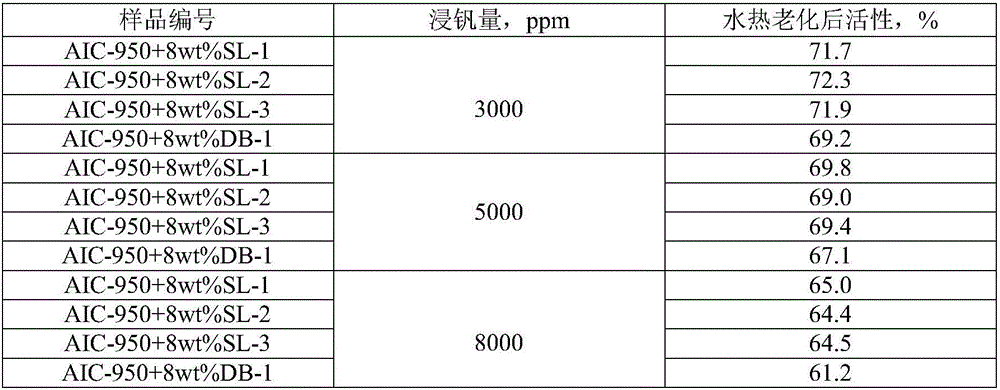

Embodiment 1

[0055] (1) 100 grams of spent catalyst A is beaten with 800 grams of water, and 150 mL of oxalic acid-ammonium fluorosilicate solution is added, and the solution H 2 C 2 o 4 / (NH 4 ) 2 SiF 6 =8:1, its concentration is C 2 o 4 2- Calculated as 100g / L, react at room temperature for 1h.

[0056] (2) Filter the slurry exchanged in step (1), beat the filter cake with 800 g of water, add 240 mL of magnesium nitrate solution, adjust the pH value of the slurry to 3.1 with hydrochloric acid, and exchange at room temperature for 1 h.

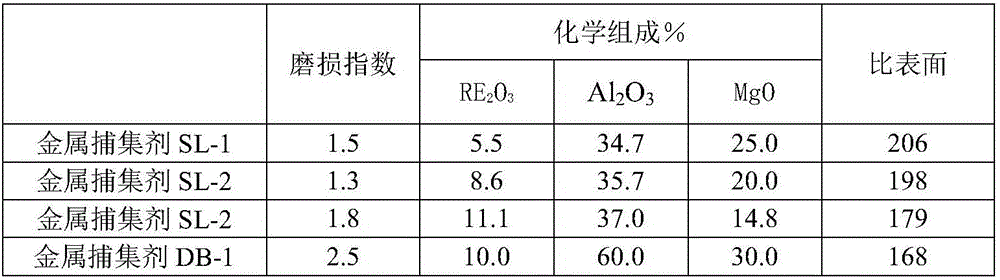

[0057] (3) Filter the slurry exchanged in step (2), rinse 53.3mL of lanthanum chloride solution, and dry the filter cake to obtain the title product, which is denoted as SL-1.

Embodiment 2

[0059] (1) 100 grams of spent catalyst B is beaten with 850 grams of water, and 300 mL of oxalic acid-ammonium fluorosilicate solution is added, and the solution H 2 C 2 o 4 / (NH 4 ) 2 SiF 6 =4.5:1, its concentration is C 2 o 4 2- Calculated as 100g / L, react at room temperature for 2h.

[0060] (2) Filter the slurry exchanged in step (1), beat the filter cake with 800 g of water, add 186.6 mL of magnesium nitrate solution, adjust the pH value of the slurry to 3.2 with hydrochloric acid, and exchange at room temperature for 2 hours.

[0061] (3) Filter the slurry exchanged in step (2), rinse with 80.0 mL of lanthanum chloride solution, and dry the filter cake to obtain the title product, which is denoted as SL-2.

Embodiment 3

[0063] (1) 100 grams of spent catalyst C is beaten with 900 grams of water, and 450 mL of oxalic acid-ammonium fluorosilicate solution is added, and the solution H 2 C 2 o 4 / (NH 4 ) 2 SiF 6 =1:1, its concentration is C 2 o 4 2- Calculated as 100g / L, react at room temperature for 3h.

[0064] (2) Filter the slurry exchanged in step (1), beat the filter cake with 800 g of water, add 133.3 mL of magnesium nitrate solution, adjust the pH value of the slurry to 3.2 with hydrochloric acid, and exchange at room temperature for 3 hours.

[0065] (3) Filter the slurry exchanged in step (2), rinse with 100.0 mL of lanthanum chloride solution, and dry the filter cake to obtain the title product, which is designated as SL-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com