Microwave burning preparation method of nano gadolinium oxide powder

A technology of nano-gadolinium oxide and microwave combustion, which is applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of long preparation process and cumbersome process, and achieve the promotion of powder crystallization, uniform heat distribution, and difficulty in agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

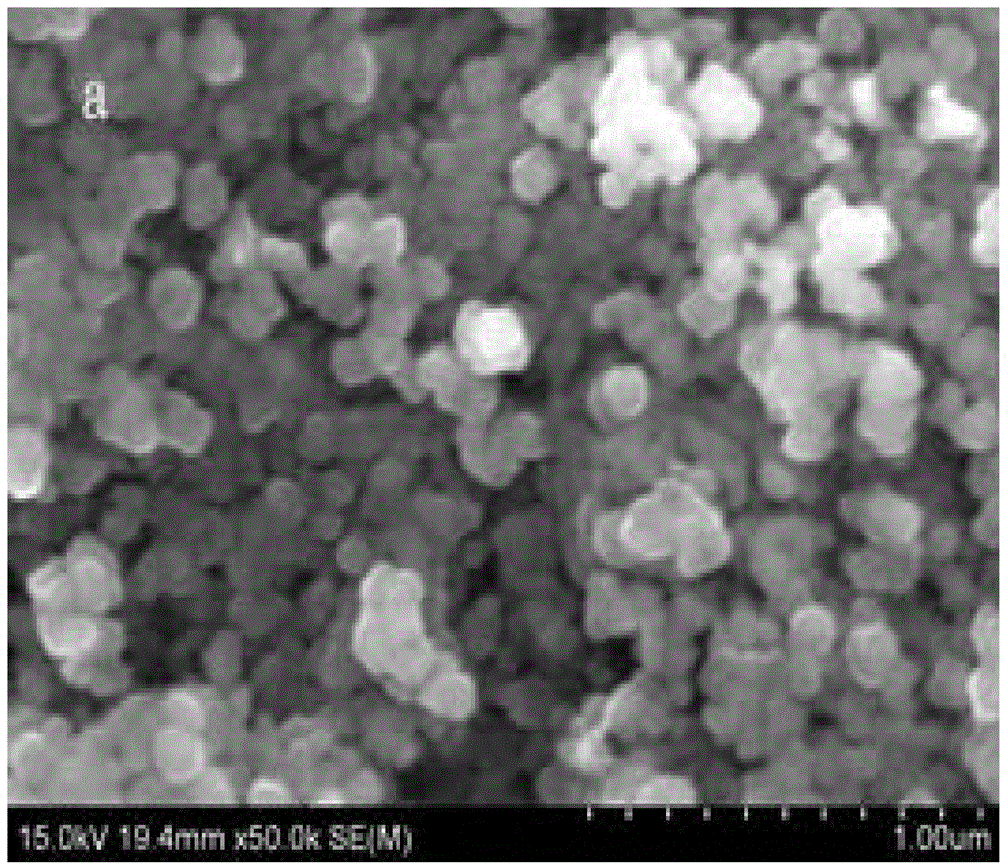

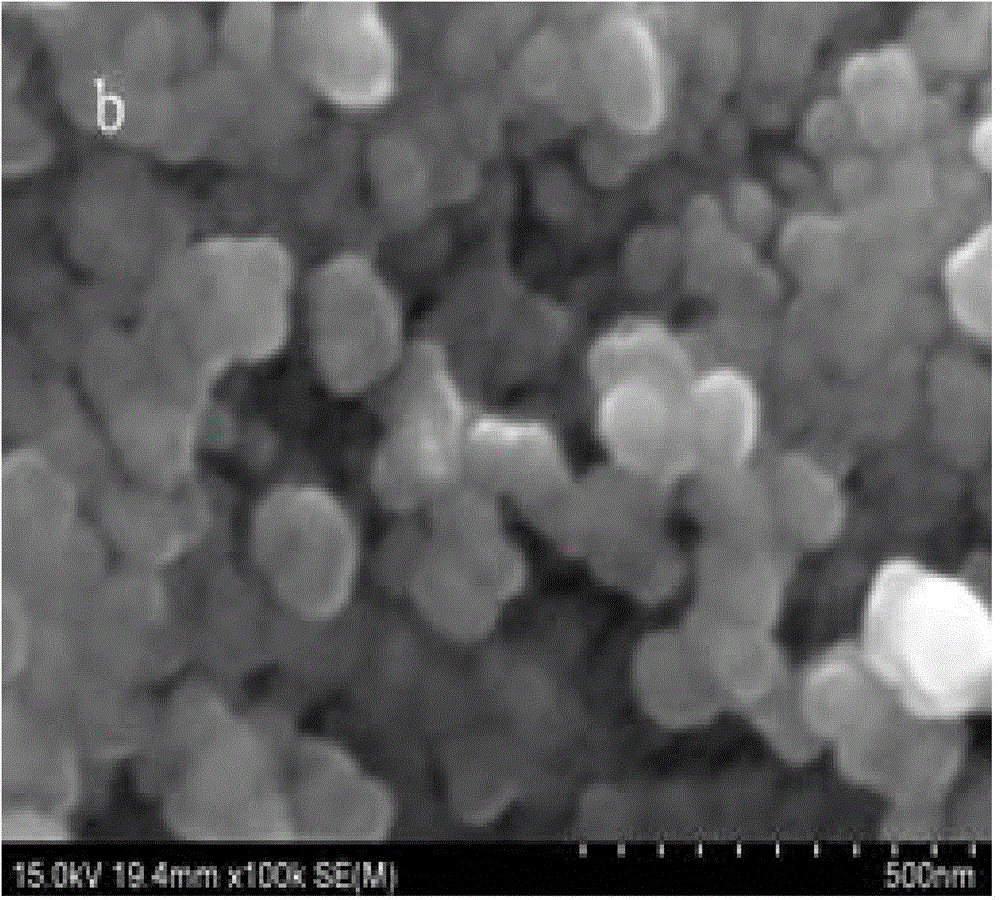

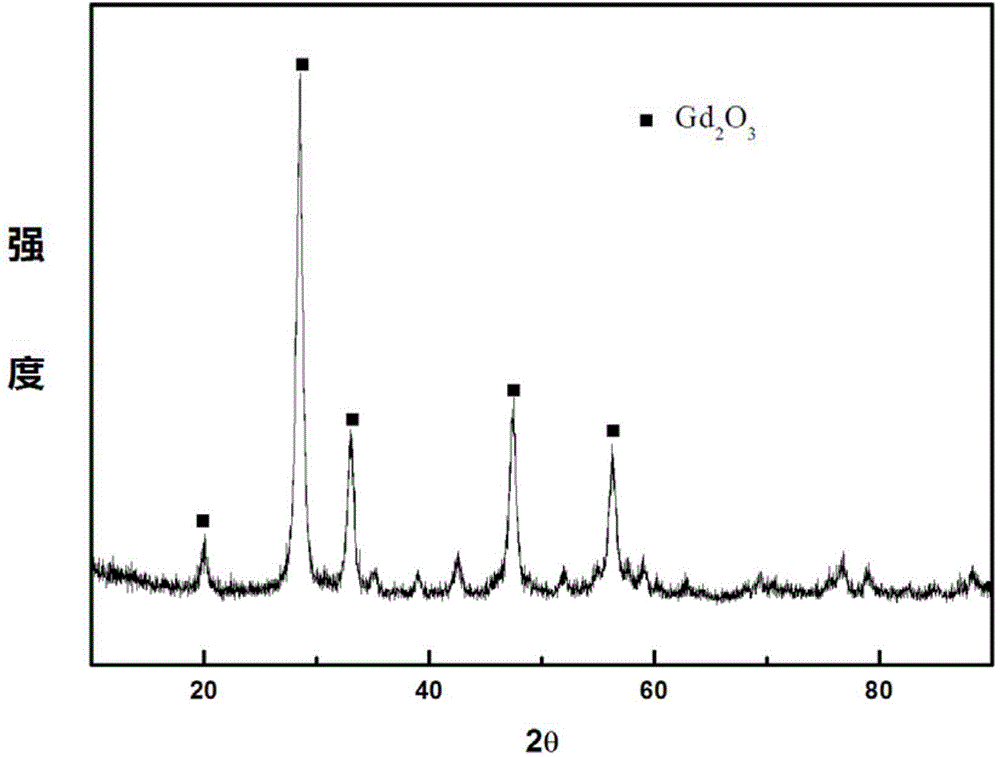

Image

Examples

Embodiment 1

[0033] A method for preparing nanometer gadolinium oxide powder by microwave combustion, comprising the following steps:

[0034] (1) Configure Gd(NO 3 ) 3 Solution: Weigh 20g of micron-sized gadolinium oxide powder, dilute 31.2g of concentrated nitric acid with a mass fraction of 69% to 35wt% with 28.2g of deionized water, by molar ratio Gd 2 o 3 :HNO 3 =1:6, configure Gd(NO 3 ) 3 Solution, put the solution in a 500ml beaker, stir and dissolve it with a magnetic stirrer, and disperse it by ultrasonic for 5min;

[0035] (2) Gadolinium nitrate solution is mixed with citric acid: take 92.4g monohydrate citric acid and dissolve it in 150ml water, by molar ratio Gd 3+ :C 6 h 8 o 7 ·H 2 O=4:1 Prepare the precursor solution, place it in a constant temperature water bath at 50°C, and stir it magnetically for 10 minutes;

[0036] (3) Adjust the pH value: add ammonia water dropwise to the precursor solution to adjust the pH value to 8;

[0037] (4) Microwave combustion synt...

Embodiment 2

[0042] A method for preparing nanometer gadolinium oxide powder by microwave combustion, comprising the following steps:

[0043] (1) Configure Gd(NO 3 ) 3 Solution: take by weighing 20g micron grade gadolinium oxide powder, 36.6g mass fraction 68% concentrated nitric acid is diluted to 35wt% with 32.9g deionized water concentrated nitric acid, by molar ratio Gd 2 o 3 :HNO 3 =1:7 configure Gd(NO 3 ) 3 Solution, put the solution in a 500ml beaker, stir and dissolve it with a magnetic stirrer, and disperse it ultrasonically for 5 minutes;

[0044] (2) Gadolinium nitrate solution is mixed with citric acid: take 92.4g monohydrate citric acid and dissolve it in 150ml water, by molar ratio Gd 3+ :C 6 h 8 o 7 ·H 2 O=4:1 Prepare the precursor solution, place it in a constant temperature water bath at 50°C, and stir it magnetically for 10 minutes;

[0045] (3) Adjust the pH value: add ammonia water dropwise to the precursor solution to adjust the pH value to 10;

[0046] (4...

Embodiment 3

[0050] A method for preparing nanometer gadolinium oxide powder by microwave combustion, comprising the following steps:

[0051] (1) Configure Gd(NO 3 ) 3 Solution: Weigh 20g of micron-sized gadolinium oxide powder, 36.6g of mass fraction 68% concentrated nitric acid, dilute the concentrated nitric acid to 35wt% with 28.2g of deionized water, by molar ratio Gd 2 o 3 :HNO 3 =1:8 configure Gd(NO 3 ) 3 Solution, put the solution in a 500ml beaker, stir and dissolve it with a magnetic stirrer, and disperse it ultrasonically for 5 minutes;

[0052] (2) Gadolinium nitrate solution is mixed with citric acid: take 92.4g monohydrate citric acid and dissolve it in 150ml, by molar ratio Gd 3+ :C 6 h 8 o 7 ·H 2 O=4:1.5 Prepare the precursor solution, place it in a constant temperature water bath at 50°C, and stir it magnetically for 10 minutes;

[0053] (3) adjust the pH value: add ammonia water dropwise to the precursor solution to adjust the pH value to 9;

[0054] (4) Micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com