Harmless treatment method of red sludge in after-treatment liquid of cold galvanizing

A harmless treatment and post-processing technology, applied in dehydration/drying/concentrated sludge treatment, iron oxide, iron oxide/iron hydroxide, etc., can solve secondary pollution of the environment, waste of resources, inability to be effectively utilized, etc. problems, to achieve the effect of solving secondary pollution, benefiting environmental protection, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

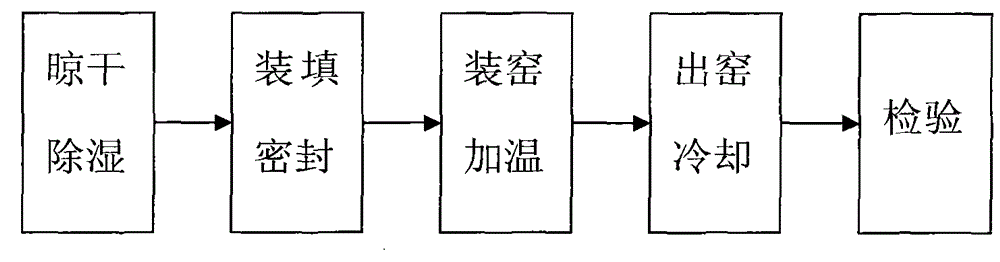

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] As shown in the process flow diagram of the present invention, the present invention comprises the following steps:

[0014] A. Drying and dehumidification: Transport the red mud to the shed area and stack it naturally. After drying until it is basically dry mud or slightly wet, it can be filled and sealed. The slightly wet moisture content of the red mud should be controlled at about 17%;

[0015] B. Filling and sealing: choose a high-temperature resistant container, put the air-dried red mud into the container and compact it to minimize the air trapped in the red mud to ensure the quality of the heating treatment, and then cover and seal, that is, put the lid on Use mud or other materials that are resistant to high temperature and not easy to shrink and deform tightly at the joint with the mouth of the high temperature resistant container to ensure the tight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com