Geopolymer fiber reinforced concrete and preparation method thereof

A geopolymer and reinforced concrete technology, applied in the field of building materials, can solve the problems of reducing natural sand and gravel mining, achieve the effects of reducing environmental damage and pollution, reducing production energy consumption, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

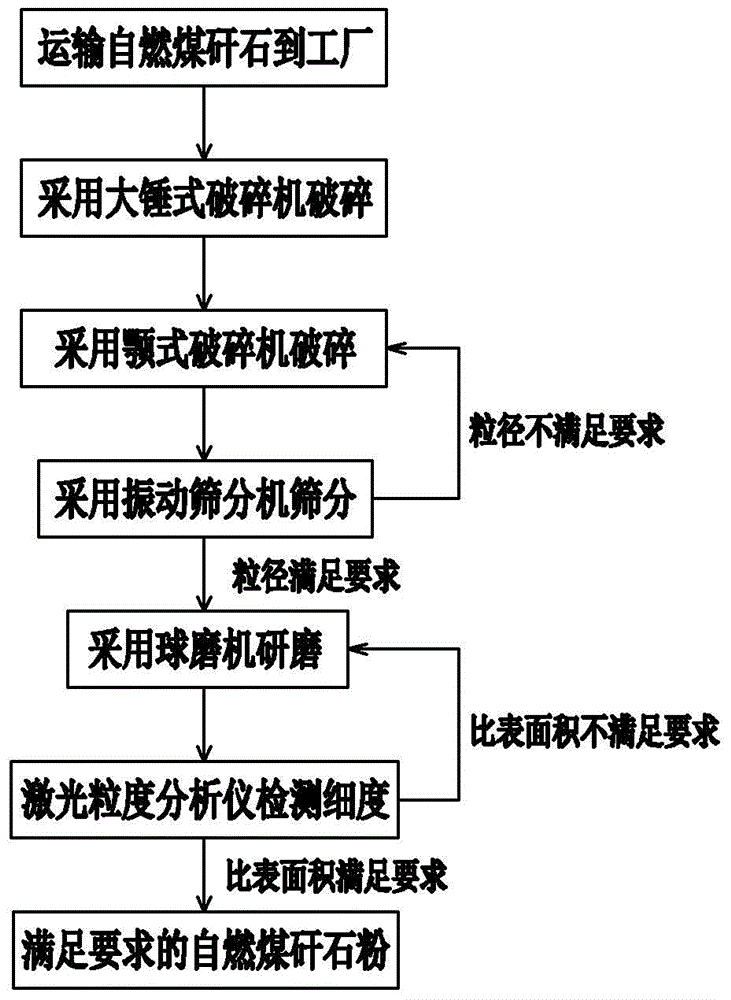

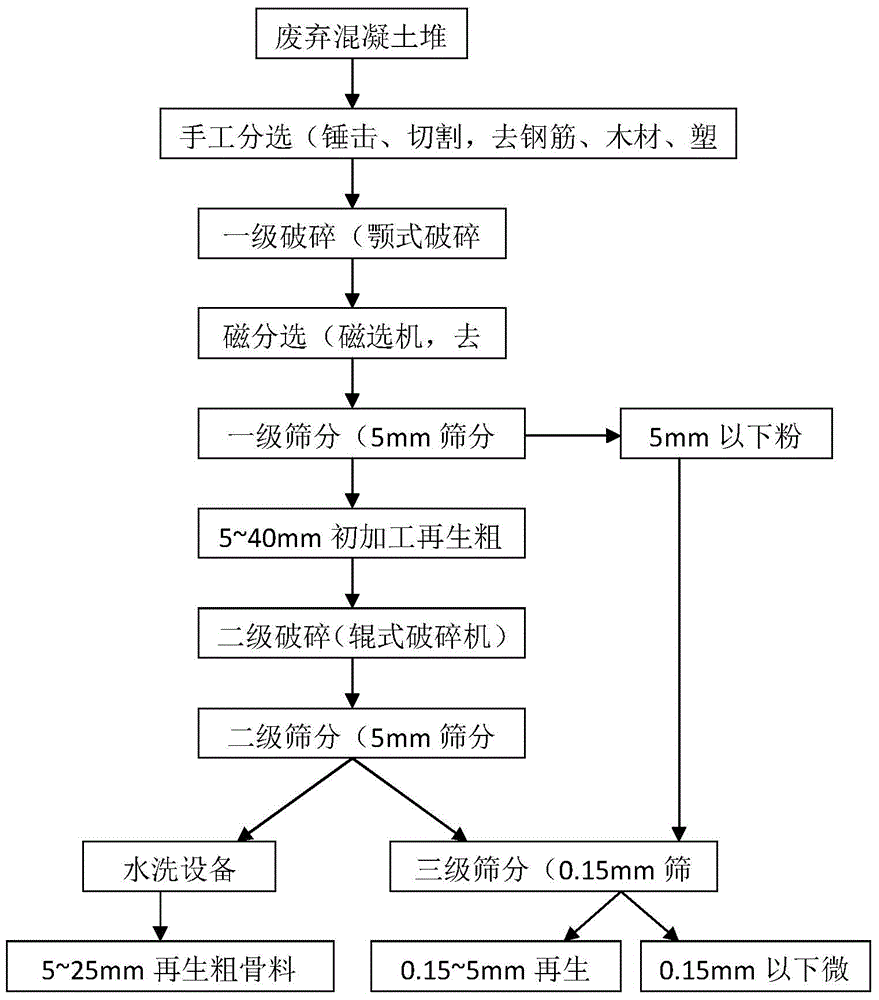

Method used

Image

Examples

Embodiment 1

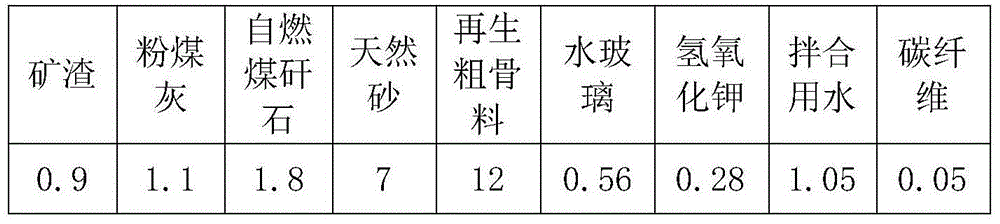

[0034] Embodiment 1: the dosage of each component is shown in Table 1 below

[0035] Table 1: Mix ratio of carbon fiber geopolymer recycled concrete

[0036]

Embodiment 2

[0037] Embodiment 2: the dosage of each component is shown in Table 2 below

[0038] Table 2: Mix ratio of carbon fiber geopolymer recycled concrete

[0039]

Embodiment 3

[0040] Embodiment 3: the dosage of each component is shown in Table 3 below

[0041] Table 3: Mix ratio of carbon fiber geopolymer recycled concrete

[0042]

[0043]The applicant has tested the performance of the product obtained in the above examples, and its performance indicators all meet the requirements of the national standards for concrete performance indicators in the relevant construction industry, and its performance is not lower than that of cement and sand and gravel as the main components on the market. traditional concrete. Specific experiments have shown that its 28-day compressive strength is not less than 200MPa, the tension-compression ratio is not less than 0.09, and its fracture performance and flexural toughness are significantly higher than those of traditional cement concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com