Preparation method of zeaxanthine

A technology of zeaxanthin and corn gluten powder, which is applied in the direction of organic chemistry, can solve the problems of high operating pressure, high operating cost, and high equipment requirements, and achieve the effects of increasing added value, good stability, and high pigment content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

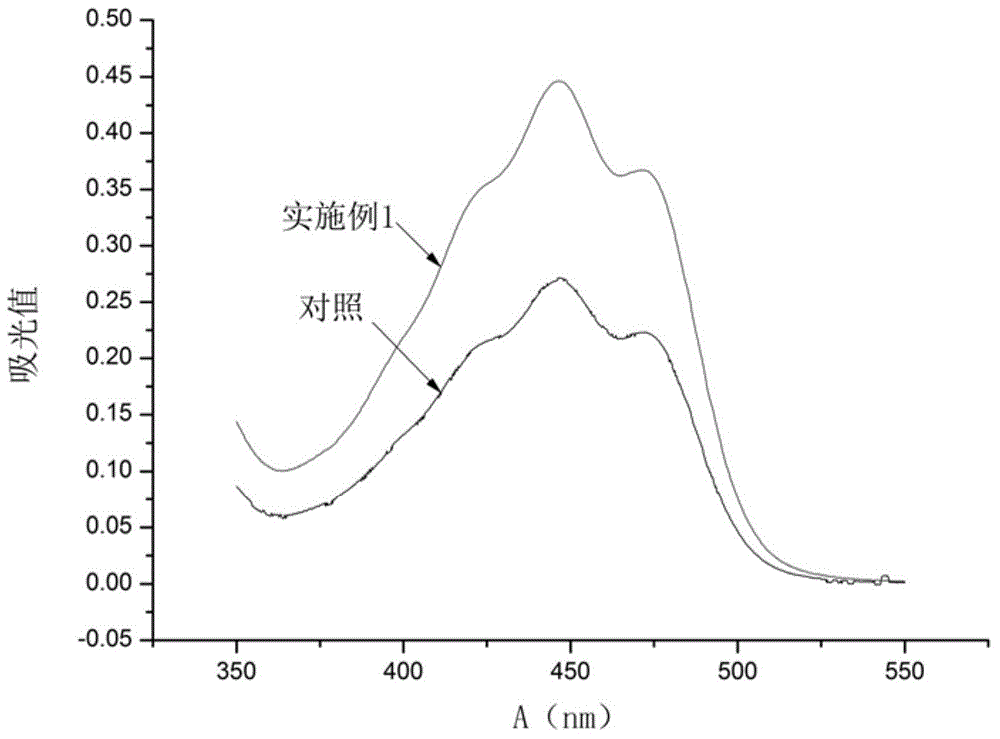

[0025] Get corn gluten powder 500g, add water, control feed liquid mass volume ratio to be 1:10 (volume unit is L, mass unit is kg), add Alcalase2.4L protease, the amount of enzyme added is 5% of the corn gluten powder quality, enzyme The hydrolysis temperature is 50°C, the pH value is 8.0, and the enzymatic hydrolysis time is 60 minutes. After the enzymatic hydrolysis, the enzyme treatment was extinguished in a 90°C water bath, the pH value was adjusted to 4.0, and centrifuged at 8000g for 30 minutes. The obtained crude extract precipitate was dissolved and extracted with absolute ethanol. The ratio of solid to liquid is 1:10 (L / kg), and the extraction time is 4h. After the extraction was completed, the extract was rotary-evaporated with a vacuum rotary evaporator. The operating temperature of the rotary evaporation was 60° C., and the rotary evaporation time was 25 minutes. Finally, 21.25 g of refined zeaxanthin was obtained. As a result of the determination, the extract h...

Embodiment 2

[0029] Get corn gluten powder 1000g, pack in the beaker of 10L. Add water, control the mass-volume ratio of feed liquid to be 1:10 (volume unit is L, mass unit is kg), add Alcalase2.4L protease, the amount of enzyme added is 5% of the corn gluten powder quality, enzymolysis temperature is 55 ℃, The pH value is 8.0, and the enzymatic hydrolysis time is 120min. After the enzymatic hydrolysis, the enzyme treatment was extinguished in a 90°C water bath, the pH value was adjusted to 4.0, and centrifuged at 8000g for 30 minutes. The obtained crude extract precipitate was dissolved and extracted with absolute ethanol. The ratio of solid to liquid is 1:15 (L / kg), and the extraction time is 4h. After the extraction was completed, the extract was rotated with a vacuum rotary evaporator. The operating temperature of the rotary evaporation was 60° C., and the rotary evaporation time was 25 minutes. Finally, 34.81 g of refined zeaxanthin was obtained.

Embodiment 3

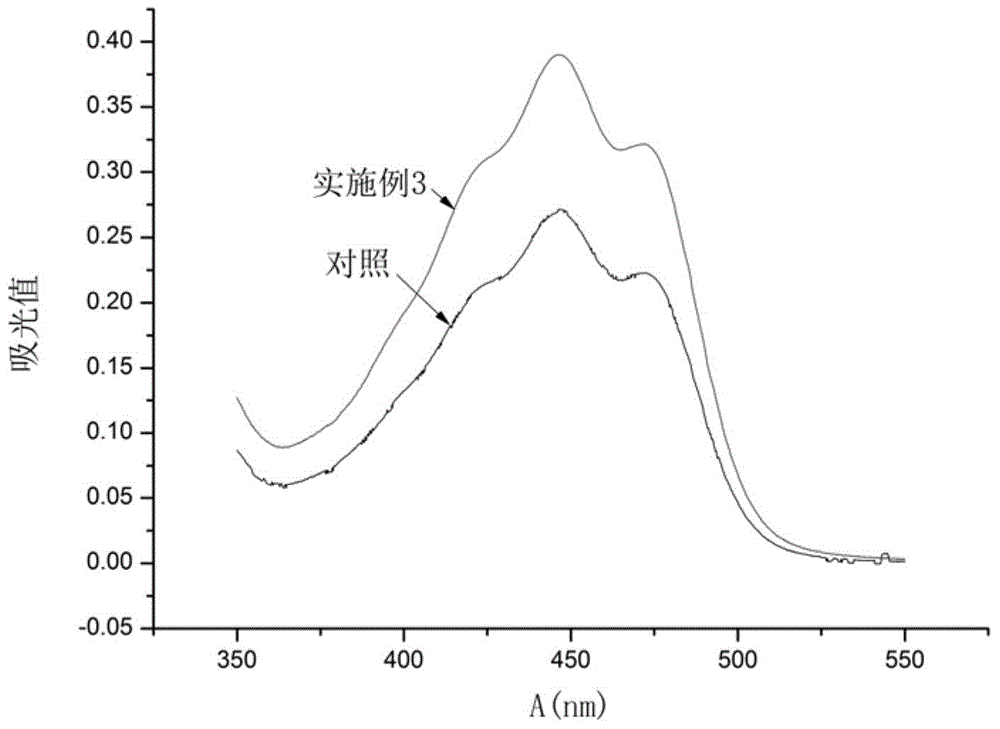

[0031] Get corn gluten powder 1000g, pack in the beaker of 10L. Add water, control the mass-volume ratio of feed liquid to be 1:10 (volume unit is L, mass unit is kg), add Alcalase2.4L protease, the amount of enzyme added is 5% of the corn gluten powder quality, enzymolysis temperature is 55 ℃, The pH value is 8.0, and the enzymatic hydrolysis time is 120min. After the enzymatic hydrolysis, the enzyme treatment was extinguished in a 90°C water bath, the pH value was adjusted to 4.0, and centrifuged at 8000g for 30 minutes. The precipitated crude extract was dissolved and extracted with n-hexane. The ratio of solid to liquid is 1:15 (L / kg), and the extraction time is 4h. After the extraction was completed, the extract was rotated with a vacuum rotary evaporator. The operating temperature of the rotary evaporation was 40° C., and the distillation time was 25 minutes. Finally, 30.23 g of refined zeaxanthin was obtained. After the above extraction is completed, the extract is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com