Surface treatment method for disposable plastic petri dish

A surface activation treatment and petri dish technology, which is applied in the fields of medicine and biology, can solve the problems of non-hydrophilicity, bacteria, difficult cell adherence culture, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

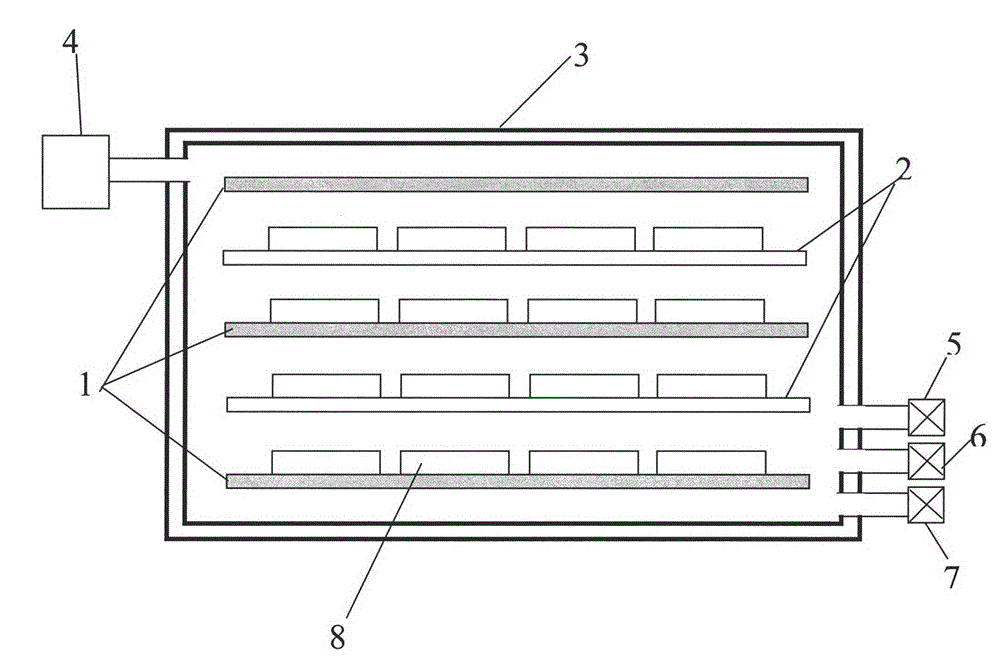

[0010] Such as figure 1 As shown, the plastic petri dish 8 is placed between the cathode plate 1 and the anode plate 2. In this embodiment, four layers can be arranged to improve efficiency.

[0011] Turn on the vacuum pump 4, and when the vacuum degree reaches 5Pa, open and adjust the nitrogen valve 5 to keep the vacuum degree at 30Pa, and apply high frequency and high voltage (40KHz, 1KV) between the cathode plate 1 and the anode plate 2. Glow discharge occurs between the anode plates, nitrogen plasma is generated, and the surface of the plastic culture dish is activated. After 2 minutes, the high-frequency high-voltage power supply and the nitrogen valve 5 are turned off in sequence.

[0012] Turn on and adjust the H 2 o 2 Steam valve 6 to keep the vacuum at 20Pa.

[0013] Then open and adjust the acrylic acid vapor valve 7 to keep the vacuum at 40Pa.

[0014] Turn on the high-frequency high-voltage power supply again, and at this time, a glow discharge is generated bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com