High-glossiness heat-resistant ABS/PET (acrylonitrile-butadiene-styrene/polyethylene terephthalate) bottle chip composite material and preparation method thereof

A composite material and high-gloss technology, applied in the field of high-gloss and heat-resistant ABS/PET bottle flake composite material and its preparation field, can solve the problem of reducing the toughness of high-gloss ABS alloy resin, the heat resistance cannot be improved, and the toughness of the composite material is reduced. and other problems, to achieve the effect of improving surface gloss and heat resistance, excellent toughness and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

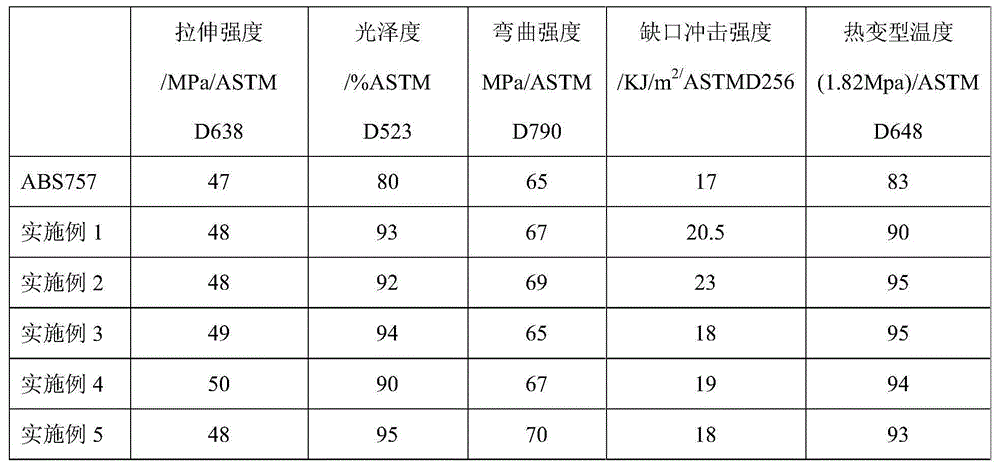

Examples

Embodiment 1

[0036] A preparation method of a high-gloss heat-resistant ABS / PET bottle flake composite material, which adopts the following raw materials and is prepared according to the following steps:

[0037] 1) Raw material composition

[0038] ABS resin 100kg, the weight percentage of acrylonitrile in this ABS resin is 18%;

[0039] ABS high rubber powder 15kg, the percentage by weight of rubber in this ABS high rubber powder is 60%;

[0040] 20kg of PET bottle flakes, the raw material of the PET bottle flakes is the copolymerization product obtained by adding isophthalic acid with a weight percentage of 2% in the conventional PET polymerization process, and its light transmittance is 80%. The viscosity number is 0.70dl / g; the PET bottle flakes are recycled PET slices with a white and transparent appearance, and the slice size is selected as 5mm×5mm;

[0041] Compatibilizer 5kg, the compatibilizer is selected as styrene-acrylonitrile-glycidyl methacrylate copolymer, its melt index ...

Embodiment 2

[0049] A preparation method of a high-gloss heat-resistant ABS / PET bottle flake composite material, which adopts the following raw materials and is prepared according to the following steps:

[0050] 1) Raw material composition

[0051] ABS resin 100kg, the weight percentage of acrylonitrile in this ABS resin is 20%;

[0052] ABS high rubber powder 20kg, the percentage by weight of rubber in this ABS high rubber powder is 50%;

[0053] 30kg of PET bottle flakes, the raw material of the PET bottle flakes is the copolymerization product obtained by adding isophthalic acid with a weight percentage of 4% in the conventional PET polymerization process, and its light transmittance is 85%. The viscosity number is 0.75dl / g; the PET bottle flakes are white and transparent recycled PET slices, and the slice size is 8mm×8mm;

[0054] Compatibilizer 10kg, the compatibilizer is selected as styrene-acrylonitrile-glycidyl methacrylate copolymer, its melt index is 9g / 10min under the conditi...

Embodiment 3

[0062] A preparation method of a high-gloss heat-resistant ABS / PET bottle flake composite material, which is prepared by using the following raw material composition, and its process operation and other parameters are set the same as in Example 1:

[0063] ABS resin 100kg, the weight percentage of acrylonitrile in this ABS resin is 24%;

[0064] ABS high rubber powder 10kg, the percentage by weight of rubber in this ABS high rubber powder is 70%;

[0065] PET bottle flakes 40kg, the raw material of the PET bottle flakes is the copolymerization product obtained by adding isophthalic acid with a weight percentage of 3% in the conventional PET polymerization process, and its light transmittance is 82%. The viscosity number is 0.60dl / g; the PET bottle flakes are white and transparent recycled PET slices, and the slice size is selected as 10mm×10mm;

[0066] Compatibilizer 20kg, the compatibilizer is selected as styrene-acrylonitrile-glycidyl methacrylate copolymer, its melt index...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com