Heat collecting plate core and flat-plate type solar thermal collector

A technology of solar heat collectors and heat-absorbing plate cores, applied in the field of solar heat collection, can solve the problems of large flow resistance of series flow channels, difficult welding process, poor dynamic characteristics, etc., achieve a high degree of standard production, reduce plate Effect of core weight and material usage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

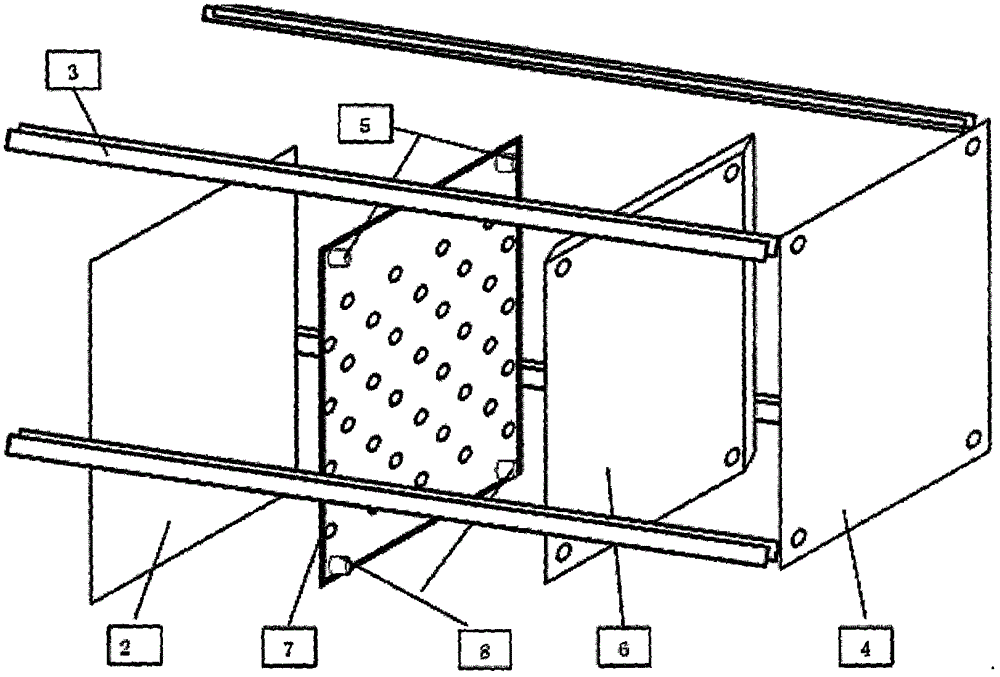

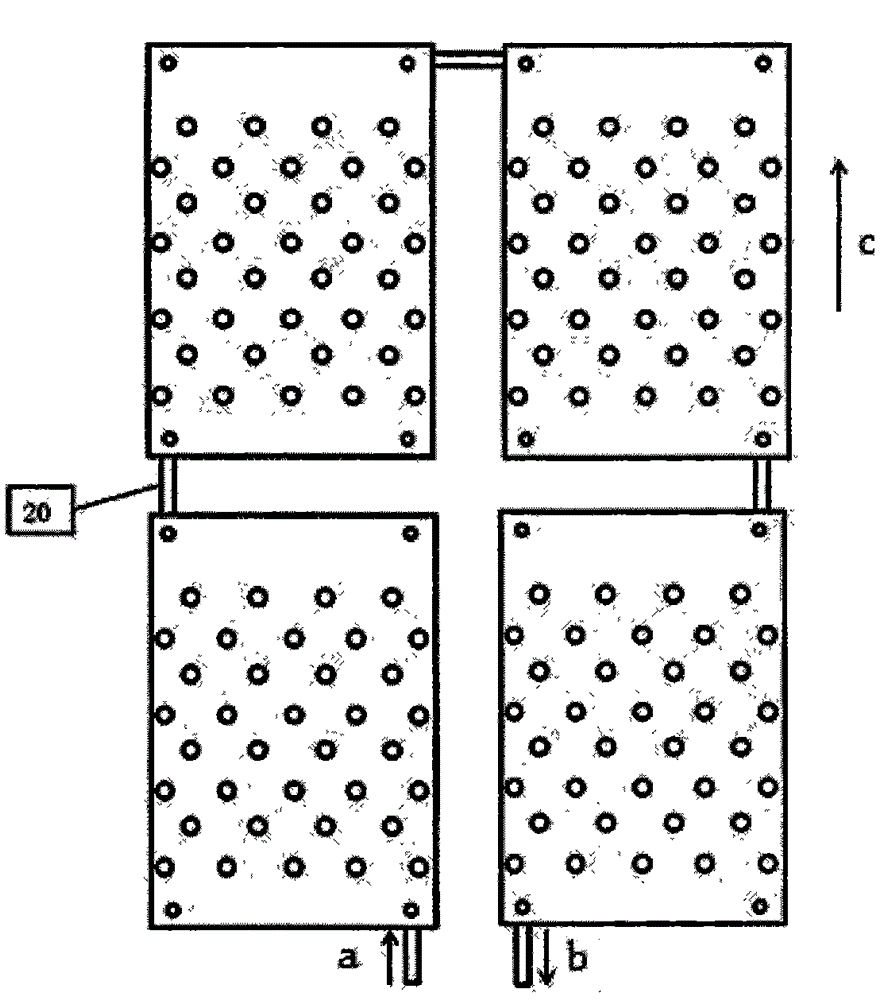

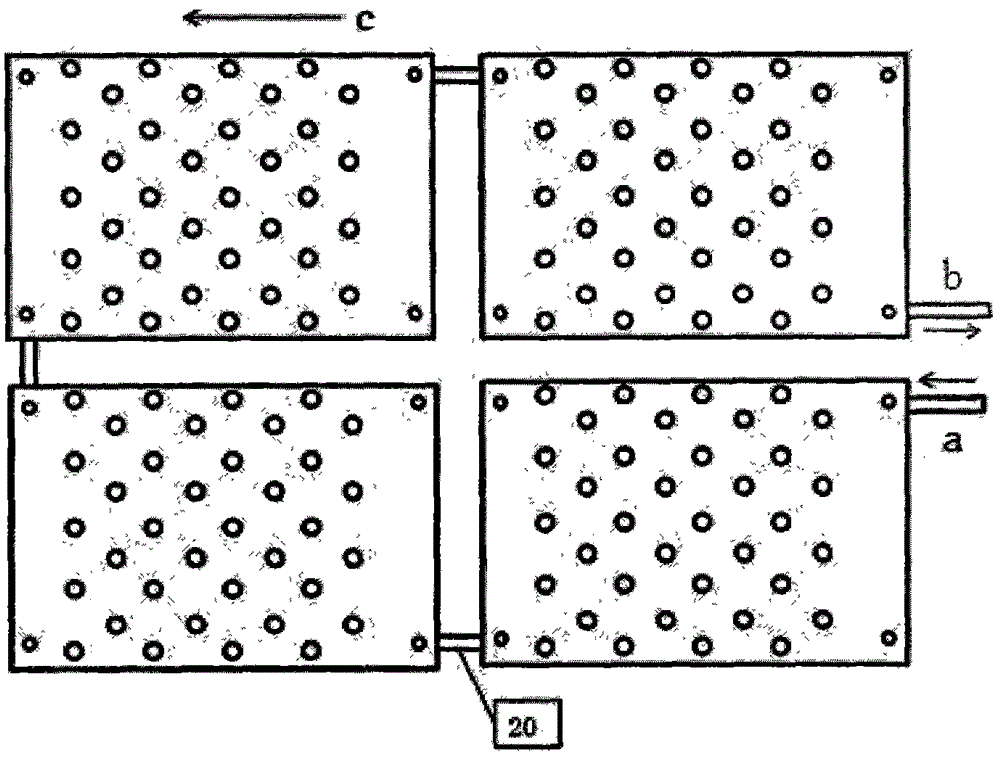

[0061] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0062] refer to Figure 1-17 , the heat-absorbing plate core 7 of the present invention is arranged in parallel by a smooth metal sheet 10 and a corrugated metal sheet 9, the outer surface of the smooth metal sheet 10 is coated with a composite solar heat-absorbing coating 11, and the inner surface of the corrugated metal sheet 9 is stamped and formed to guide Raised or ribbed12. In order to generate turbulent flow at a lower Reynolds number and improve the heat transfer efficiency of the heat-absorbing core 7, among the two metal sheets of the flat metal plate body, one is a non-corrugated flat sheet 10, and the other is stamped on the inner surface The corrugated thin plate 9 with flow-guiding protrusions or ribs 12 is formed.

[0063] The metal thin-plate heat-absorbing core 7 in the present invention does not u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com