Multi-stage internal circulation semi-dry desulfurization, denitrification and mercury removal integrated device

A technology of semi-dry desulfurization and internal circulation, which is applied in the field of flue gas purification, can solve the problems of large power consumption and difficult implementation of ozone generating devices, large resistance of cyclone separators, and high operating costs, and achieves improved treatment effect, simple structure, and reduced cost. The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

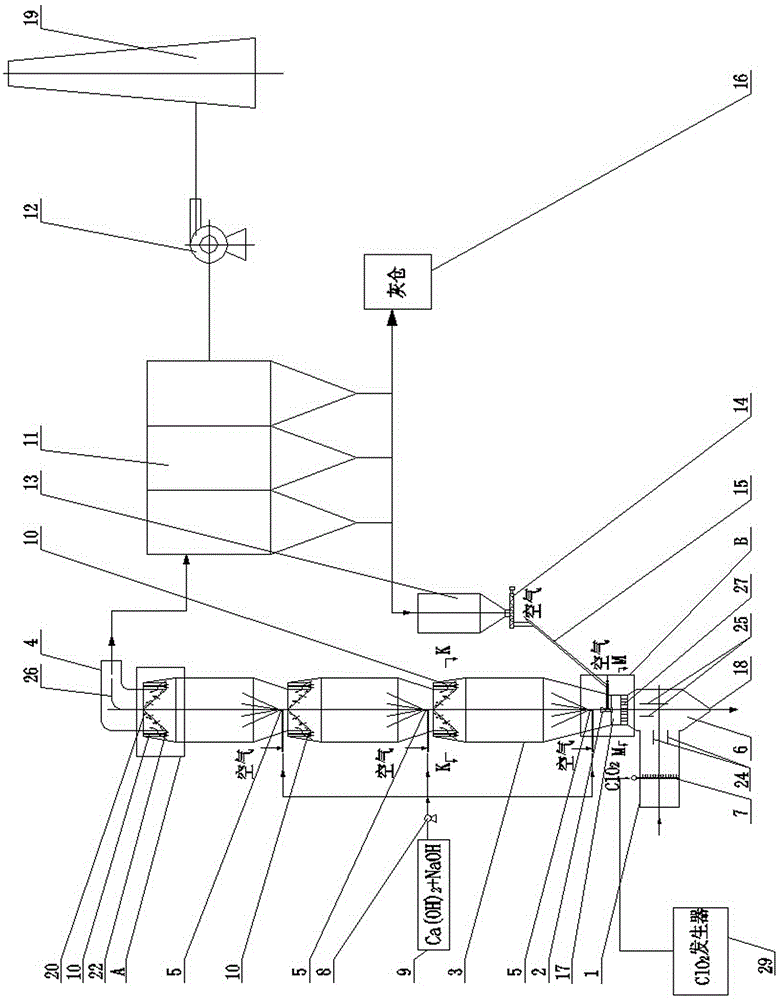

[0029] Specific implementation mode one: as Figure 1~Figure 8 As shown, the multi-stage internal circulation semi-dry desulfurization, denitrification and mercury removal integrated device includes flue gas inlet 1, small venturi tube 2, multi-stage internal circulation reactor 3, flue gas outlet 4, and multiple double lye atomizers Nozzle 5, ash hopper 6, ClO 2 Distributor 7, slurry pump 8, container filled with double lye 9, multiple U-shaped tank separators 10, bag filter 11, induced draft fan 12, ash storage tank 13, screw feeder 14, feeding pipe 15 and ash bins 16;

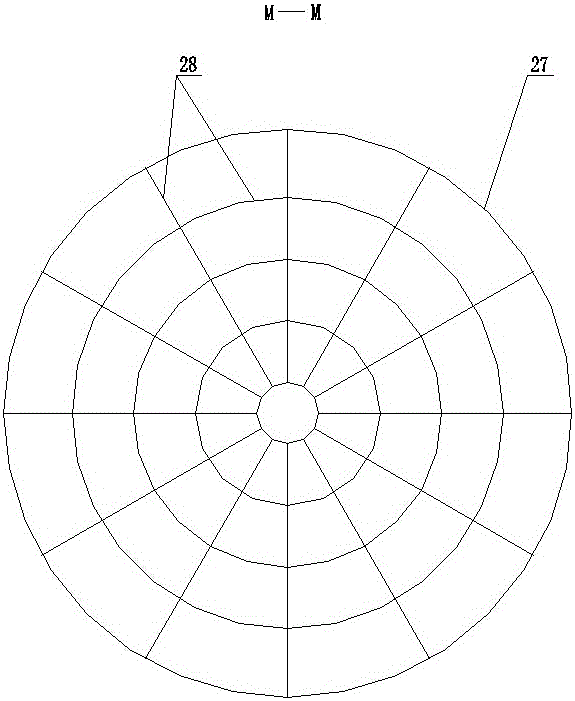

[0030]The multi-stage internal circulation reactor 3 is vertically arranged, and the multi-stage internal circulation reactor 3 is sequentially from the first-stage internal circulation reactor to the Nth-stage internal circulation reactor from bottom to top, N is a natural number, and N= 3~5; the lower part of the first-stage internal circulation reactor is a large venturi tube 17, and the large venturi t...

specific Embodiment approach 2

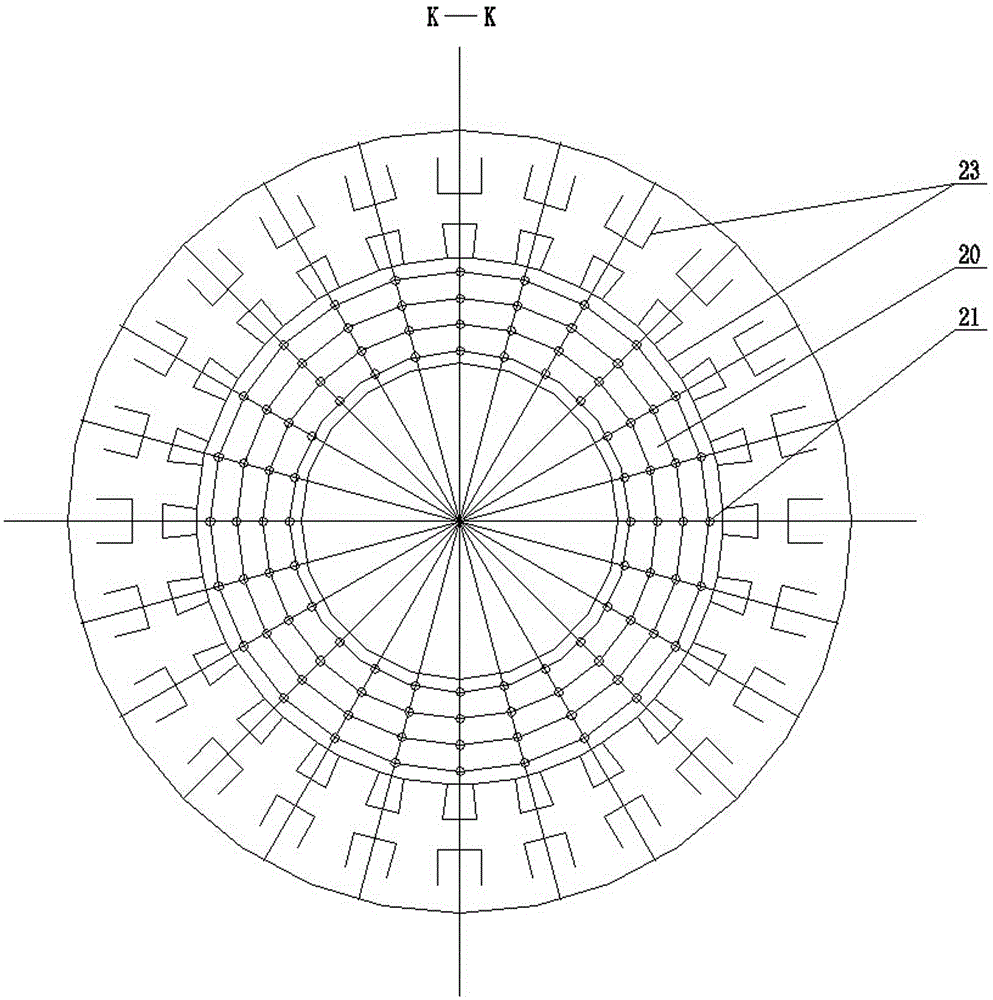

[0034] Specific implementation mode two: as figure 1 , figure 2 , Figure 4 , Figure 6~Figure 8 As shown, the specific embodiment one is the multi-stage internal circulation semi-dry desulfurization, denitrification and mercury removal integrated device, each of the U-shaped groove separators 10 includes a multi-layer U-shaped groove, and the side of the conical shell 20 Several ventilation holes 21 are processed on the wall, and the large-diameter end of the conical shell 20 is provided with an annular outer edge 22. The outside of the conical shell 20 is provided with multi-layer U-shaped grooves from the inside to the outside, and the inner U-shaped groove The lower end of the ring-shaped outer edge 22 is fixedly connected to the upper surface of the ring-shaped outer edge 22, and openings are processed on the ring-shaped outer edge 22 corresponding to the U-shaped groove in the inner layer. The upper end of the U-shaped groove is fixedly connected, and each layer of U...

specific Embodiment approach 3

[0036] Specific implementation mode three: as figure 1 As shown, the multi-stage internal circulation semi-dry integrated desulfurization, denitrification and mercury removal device described in Embodiment 1 or Two, the multi-stage internal circulation semi-dry integrated desulfurization, denitrification and mercury removal device also includes at least one horizontal guide plate 24 The at least one horizontal guide plate 24 is arranged inside the smoke inlet 1 parallel to the center line of the smoke inlet 1, and all the horizontal guide plates 24 are fixedly connected to the inner wall of the smoke inlet 1 (the purpose of setting the horizontal guide plate 24 is : used for evenly distributing the flue gas, after the flue gas passes through the horizontal guide plate 24, it is transported to the large venturi tube 17, and part of the solid particles fall into the ash hopper 6 under the action of gravity and centrifugal inertial force, and pass through the ash hopper 6's ash o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com